Multichannel gas spark switch applying plasma synthesis jet trigger technology

A gas spark switch and plasma technology, which is applied to spark gaps, spark gaps, electrical components and other directions with auxiliary triggering devices, can solve problems such as single discharge channel, electrode ablation, and low self-discharge probability, and achieve simplified structure, The effect of reducing electrode ablation and reducing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

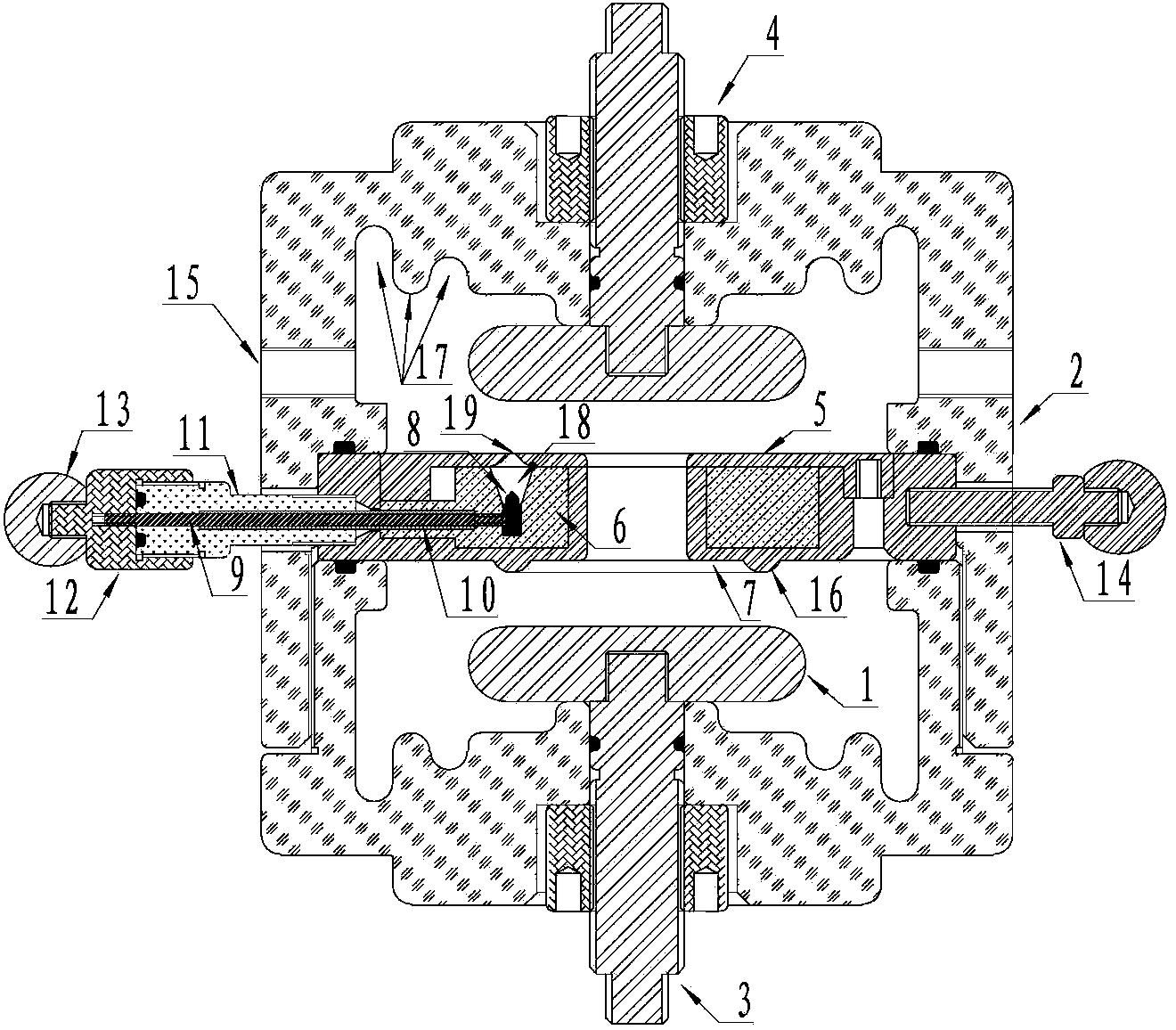

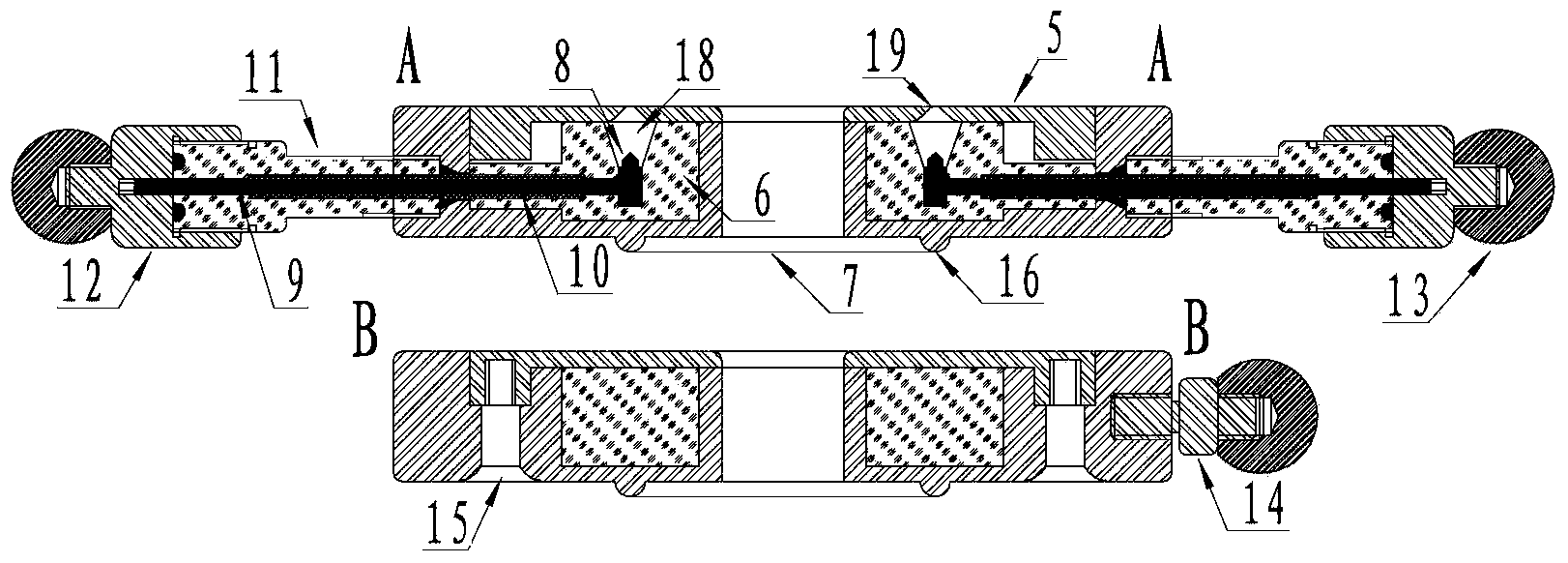

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0029] see figure 1 , showing the overall cross-section of a multi-channel gas spark switch, figure 2 Sectional views of different orientations of the trigger electrode inside the gas spark switch are shown.

[0030] A multi-channel gas spark switch with plasma synthetic jet trigger technology, comprising a switch housing 2, a trigger electrode inside the switch housing 2, a needle electrode 8 and two main electrodes 1, and on one side of the trigger electrode Spray holes 19 on the surface, wherein the two main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com