High strength alloy round aluminium rod and production method thereof

A high-strength alloy and production method technology, applied in the field of aluminum alloy materials, can solve the problems of inability to produce high-strength alloy round aluminum rods and in-depth research and development of the production process of high-strength alloy round aluminum rods, so as to achieve the improvement of tensile strength and elongation The effect of rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

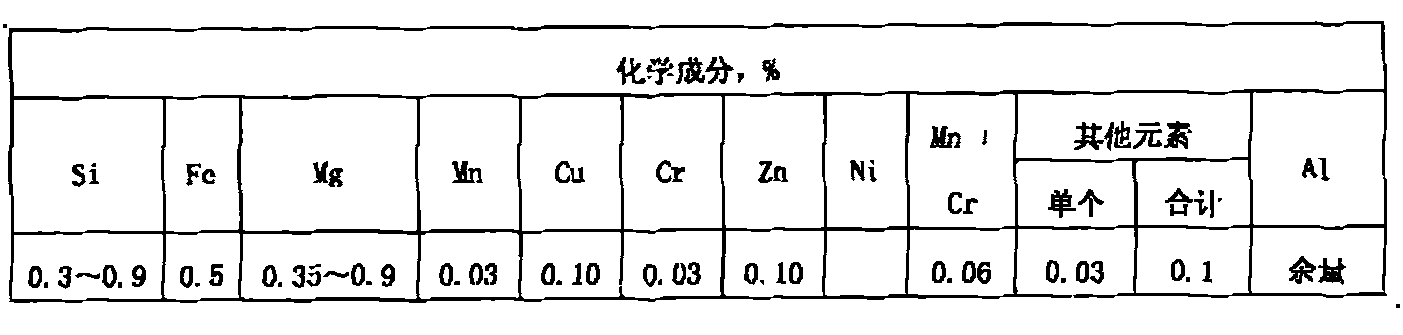

Embodiment Construction

[0021] 1. Purification and disposal of ingredients and aluminum solution

[0022] (1) Add molten aluminum with a content of more than 99.5% in the furnace, and control the temperature between 760 and 800°C;

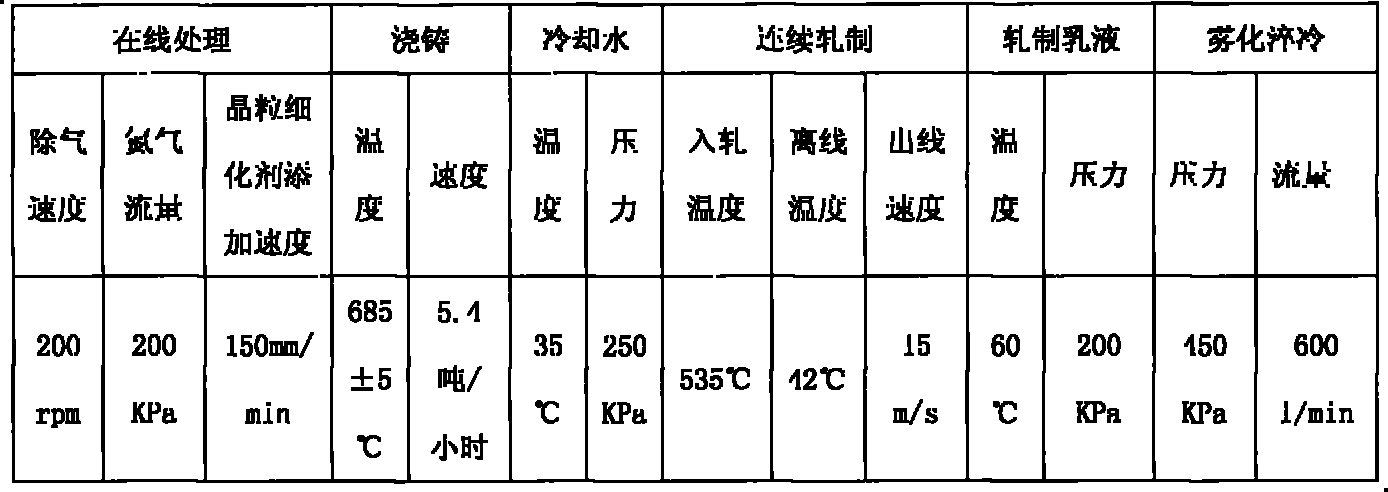

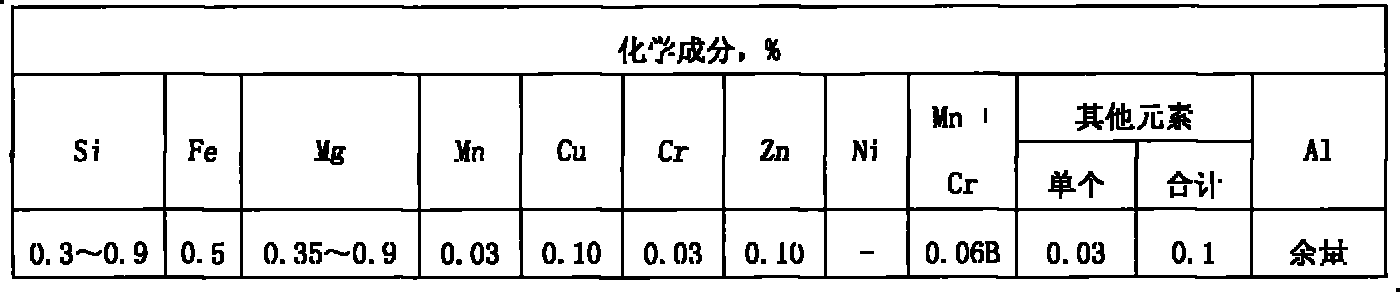

[0023] (2) After accurate calculation, metals such as silicon and magnesium and iron (or intermediate alloys such as titanium and aluminum boron) are added, and the content is controlled to be Si≤0.6%, Fe≤0.3%, Mg: 0.3-0.9% (chemical Other elements in the composition are regarded as impurities, not added, just monitored during composition analysis, and do not exceed the upper control limit); the chemical composition requirements in the formula are shown in Table 1:

[0024] Table 1 Chemical Composition Requirements Table

[0025]

[0026] (3) Add silicon and iron metals to the smelting furnace for smelting, keep at a temperature of 760-800°C for 30-40 minutes, and use electromagnetic stirring to stir thoroughly and evenly for half an hour, then add pure metal magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com