High-chromium martensitic heat-resistant steel and manufacturing method thereof

A manufacturing method and technology of heat-resistant steel, applied in the field of heat-resistant alloys, can solve the problem of not being able to meet the requirements of oxidation resistance and creep resistance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

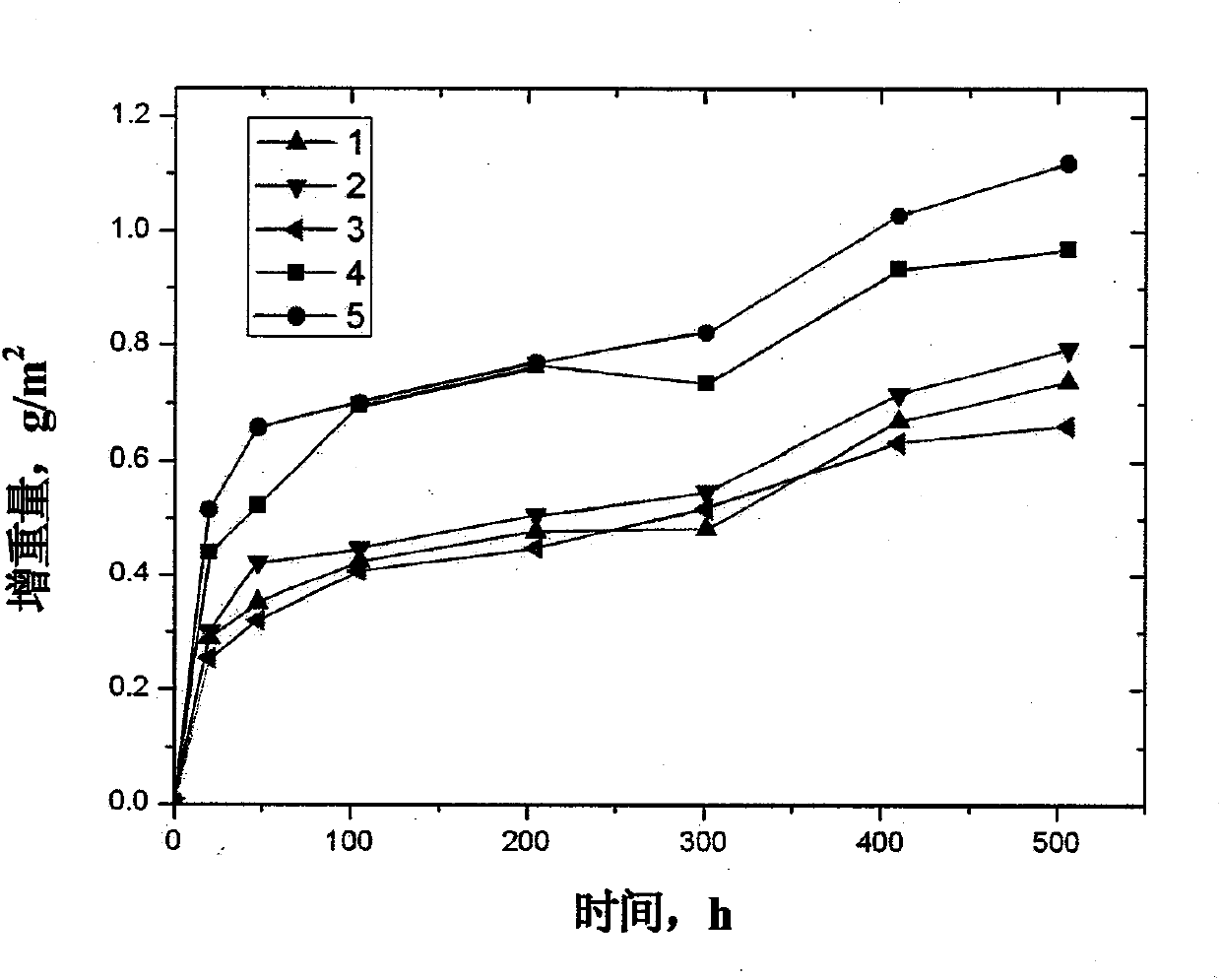

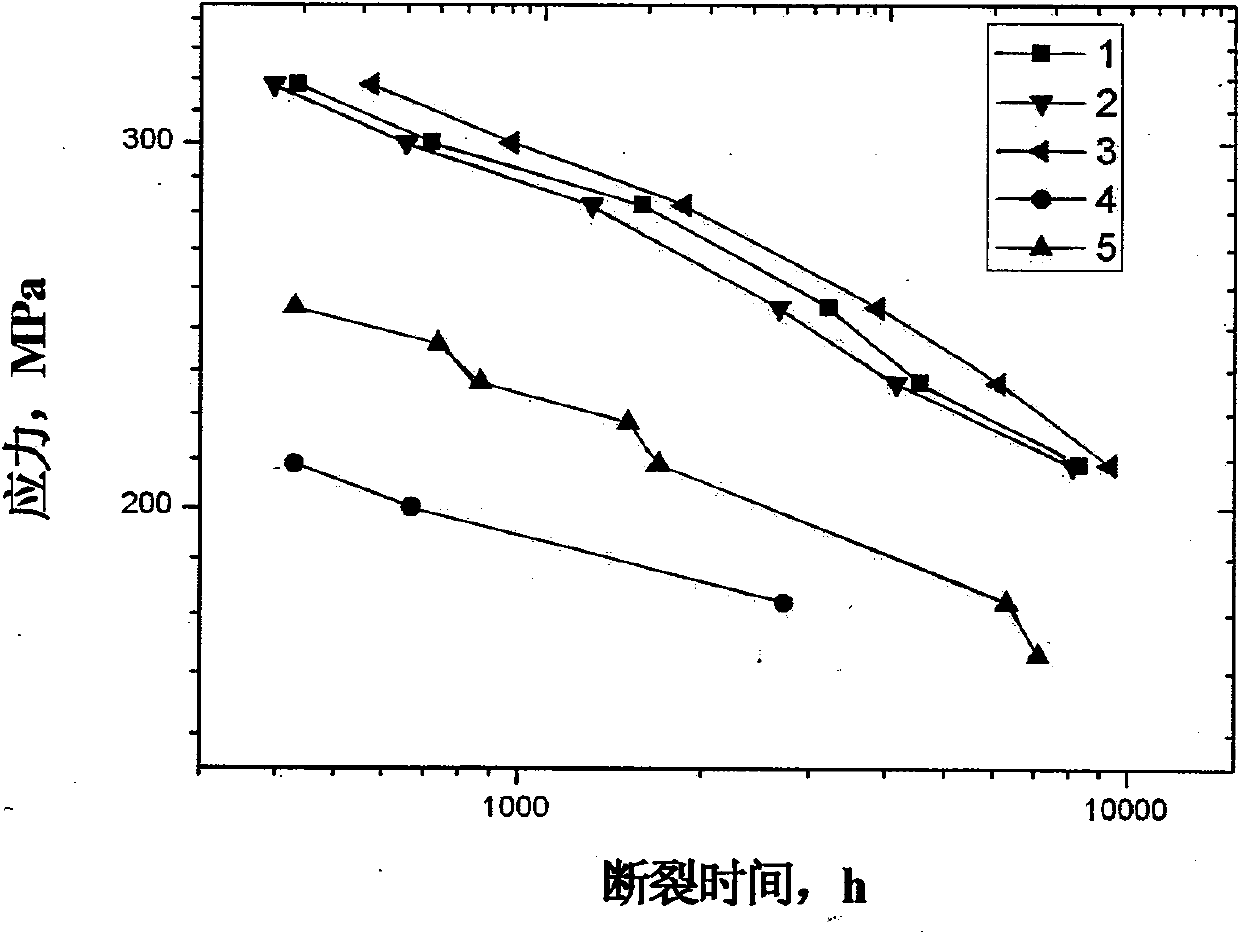

[0051] Table 1 lists three heat-resistant steels whose composition is within the composition range specified by the present invention and two comparative steels whose composition deviates from the composition range specified by the present invention. Steel No. 4 is ASME P92 steel, which does not contain the Co element required to be added in the composition specified in the present invention, and the W content is lower than the lower limit specified in the present invention. The Co and W contents of No. 5 steel are both lower than the lower limit specified in the present invention.

[0052] After the above heat-resistant steel is mixed, it is put into a vacuum induction furnace for melting. After smelting, the ingot is subjected to thermal processing and heat treatment according to the following process conditions:

[0053] (1) Heated forging in the austenitic single-phase zone, the initial forging temperature is 1150°C, the final forging temperature is 850°C, the forging-pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com