Heat-resistant magnesium alloy and preparation method thereof

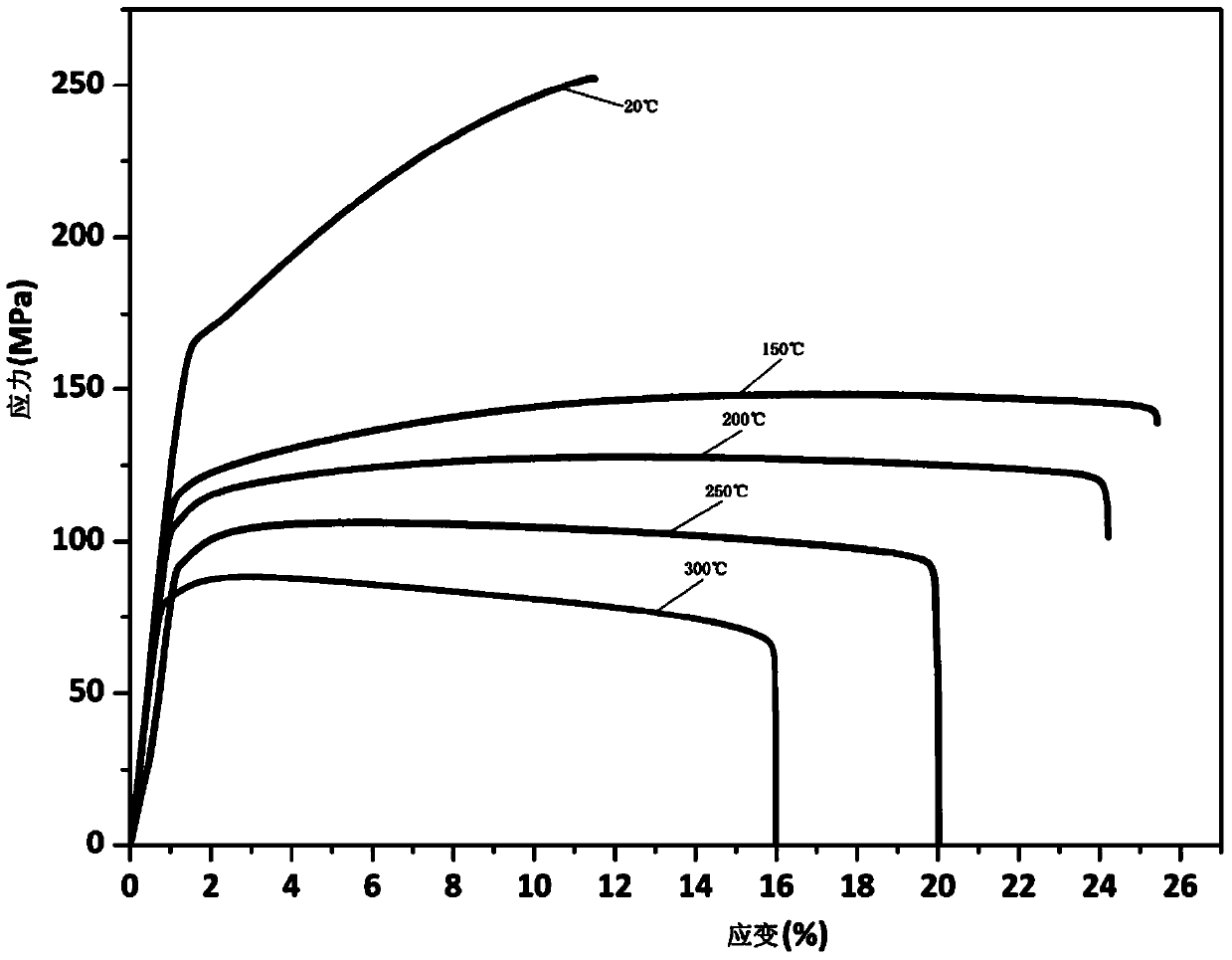

A magnesium alloy, heat-resistant technology, applied in the field of magnesium alloys, can solve the problems of unsatisfactory use requirements, poor mechanical properties and creep resistance, etc., achieve good solid solution strengthening effect, improve mechanical properties and creep resistance , good mechanical properties and creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing a heat-resistant magnesium alloy, comprising the following steps:

[0043] 1), melting magnesium source, aluminum source, lanthanum source, samarium source and manganese source to obtain alloy liquid;

[0044] 2), die-casting the alloy liquid to obtain a heat-resistant magnesium alloy, the heat-resistant magnesium alloy comprising:

[0045] 3.5wt% to 4.5wt% of Al, 2.5wt% to 3.5wt% of La, 1.5wt% to 3.0wt% of Sm, 0.2wt% to 0.4wt% of Mn, and a total amount of impurity elements less than 0.03wt%, The balance is magnesium.

[0046] In the invention, magnesium source, aluminum source, lanthanum source, samarium source and manganese source are smelted to obtain alloy liquid. In the present invention, the melting temperature is preferably 740°C to 765°C, more preferably 750°C to 760°C, and most preferably 755°C. The present invention has no special limitation on the smelting method, and the technical scheme of metal smelting well...

Embodiment 1

[0065] Preheat 22600g of pure magnesium, 1400g of pure aluminum, 7000g of magnesium-lanthanum master alloy, 3000g of magnesium-samarium master alloy and 6000g of magnesium-manganese master alloy to 200°C. Put pure magnesium and magnesium-manganese master alloy preheated to 200°C into a crucible preheated to 320°C, and pour SF into the crucible 6 and CO 2 The mixed gas with a volume ratio of 1:100 is added to the crucible at 740°C under stirring conditions, and the above-mentioned magnesium-lanthanum master alloy and magnesium-samarium master alloy preheated to 200°C are mixed for 5 minutes to obtain the first A mixed metal liquid; adding the above-mentioned pure aluminum preheated to 200°C to the first mixed metal liquid and mixing for 15 minutes to obtain an alloy liquid; refining the alloy liquid with argon for 8 minutes, and refining The alloy solution was left to stand for 30 minutes.

[0066] Die-cast the above-mentioned molten alloy after standing on a cold-chamber die...

Embodiment 2

[0071] Preheat 20400g of pure magnesium, 1600g of pure aluminum, 8000g of magnesium-lanthanum master alloy, 4000g of magnesium-samarium master alloy and 6000g of magnesium-manganese master alloy to 200°C. Put pure magnesium and magnesium-manganese master alloy preheated to 200°C into a crucible preheated to 320°C, and pour SF into the crucible 6 and CO 2 The mixed gas with a volume ratio of 1:100 is added to the crucible at 750°C under stirring conditions, and the above-mentioned magnesium-lanthanum master alloy and magnesium-samarium master alloy preheated to 200°C are mixed for 6 minutes to obtain the first A mixed metal liquid; adding the above-mentioned pure aluminum preheated to 200°C to the first mixed metal liquid and mixing for 16 minutes to obtain an alloy liquid; refining the alloy liquid with argon for 9 minutes, and refining The alloy solution was left to stand for 35 minutes.

[0072] Die-cast the above-mentioned molten alloy after standing on a cold-chamber die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com