Manufacturing technique of austenitic stainless steel cold-rolled plate with good surface performance

A technology of austenitic stainless steel, manufacturing technology, applied in the direction of manufacturing tools, coatings, grinding machines, etc., can solve the problem of increased nitriding layer thickness and surface nitrogen concentration, shallow, generally only reach tens of microns, technical devices and processes Complicated problems, to achieve the effect of improved wear resistance and corrosion resistance, excellent mechanical properties, and short nitriding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Table 1 Chemical composition of 304 test paper (wt%)

[0033] Grade

C

Si

mn

P

S

Ni

Cr

N

304

0.049

0.39

1.13

0.026

0.002

8.06

18.02

0.044

[0034] The chemical composition of the 304 hot-rolled test coil with a specification of 4.0 mm is shown in Table 1. The hot-rolled test coils are first annealed and pickled, then cold-rolled to 1.2mm after pickling, and then shot-peened and degreased and degreased after cold-rolling. min, the shot peening speed is 78m / s. 304 stainless steel was annealed at 1150°C, normal pressure, and nitrogen-containing mixed atmosphere for 20 minutes, and water-cooled at a cooling rate of 5°C / S after annealing. The surface of the annealed austenitic stainless steel plate is ground to remove a 20 μm surface layer.

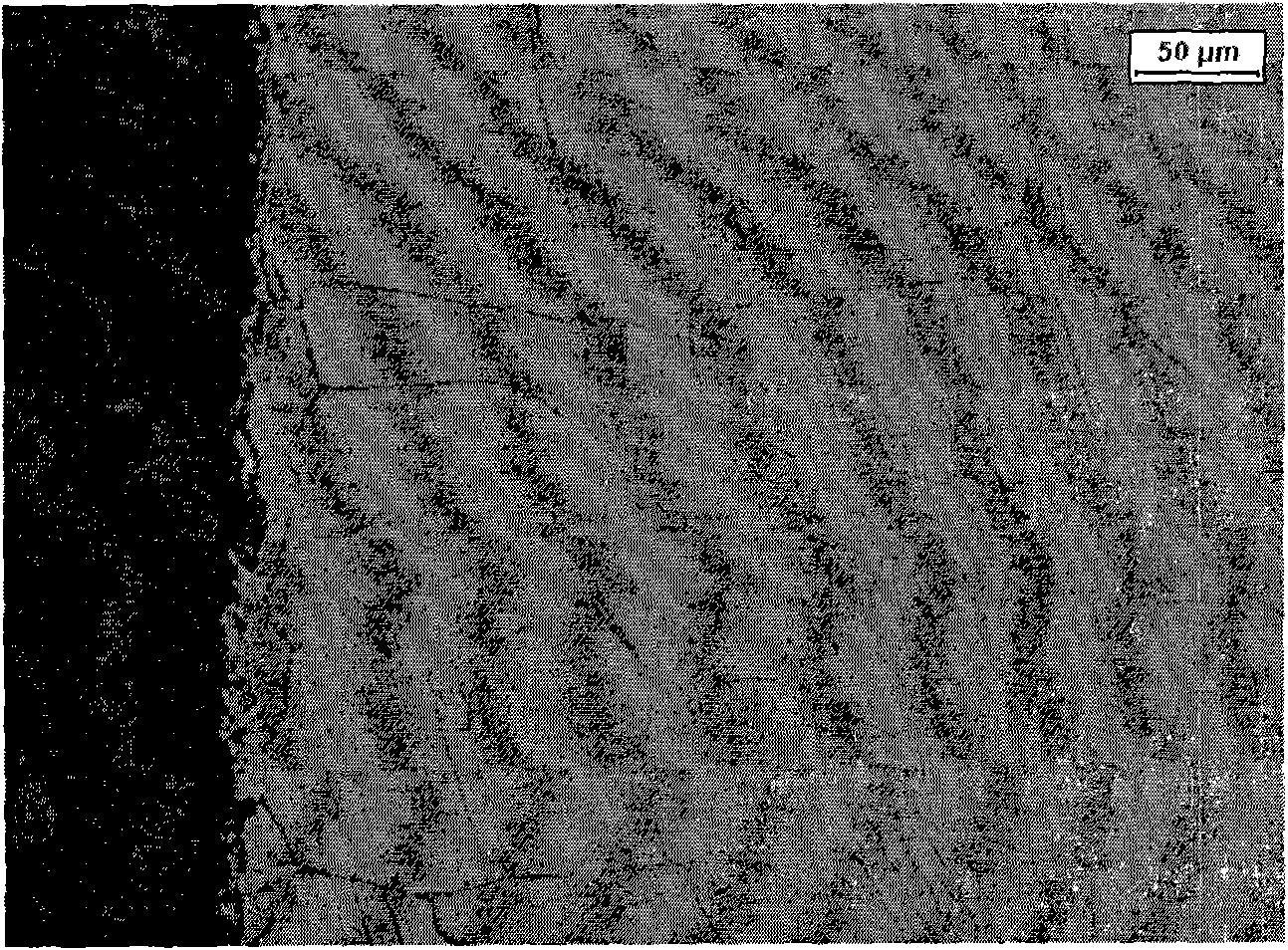

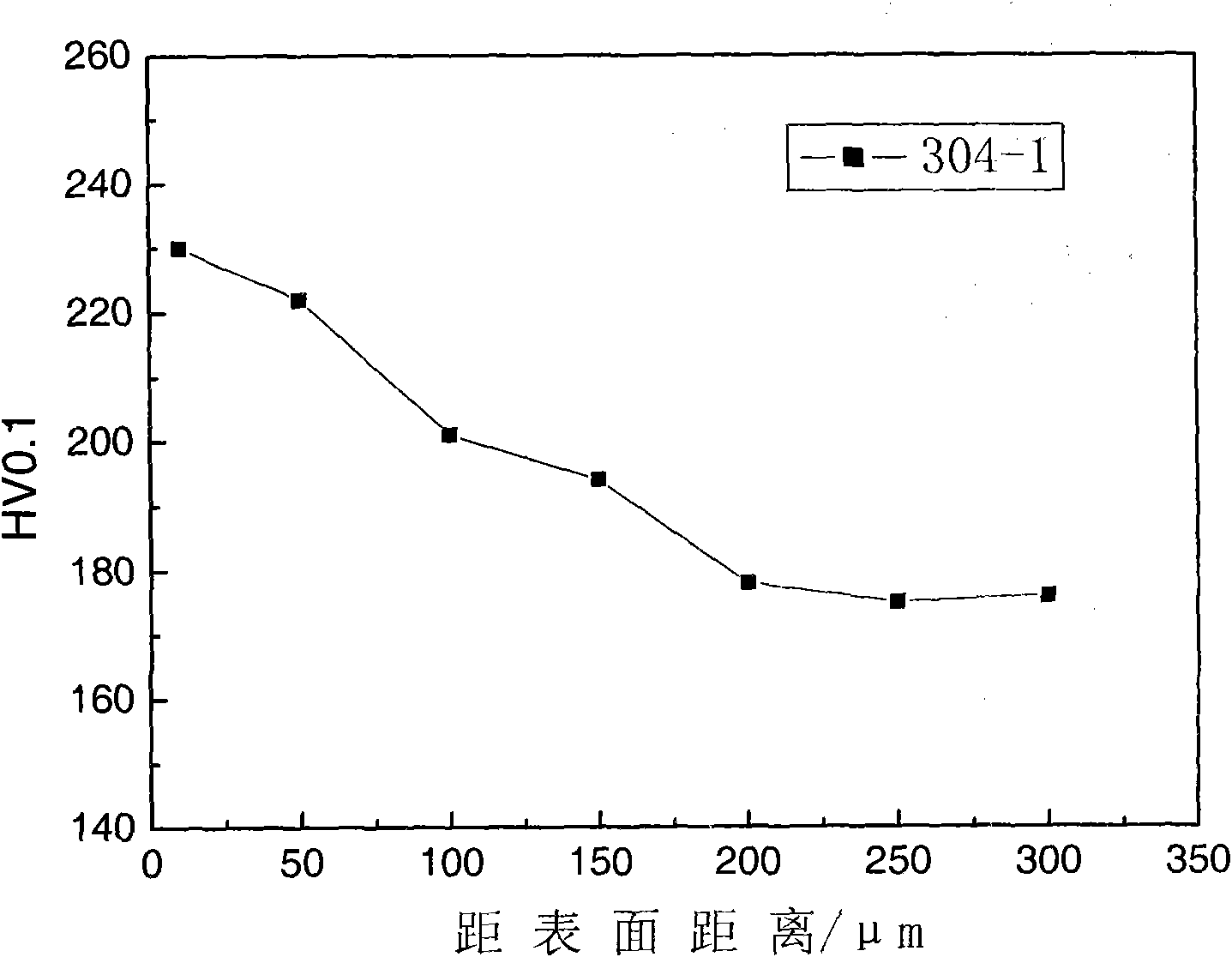

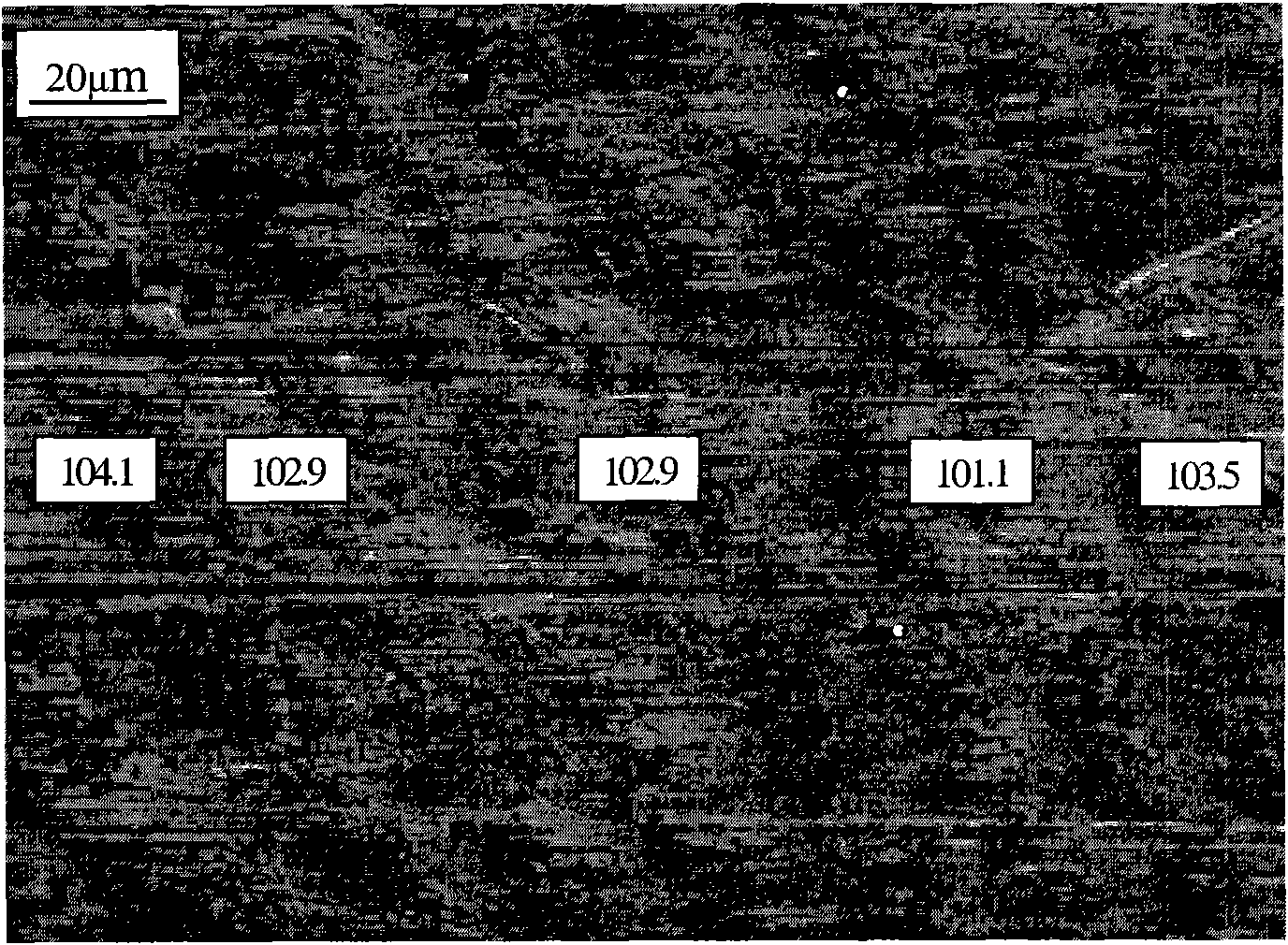

[0035] The microstructure observation and performance test were carried out on the 304 test roll sample (No. 304-1), an...

Embodiment 2

[0043] Table 3 Chemical composition of 304L test paper (wt%)

[0044] Grade

C

Si

mn

P

S

Ni

Cr

N

304L

0.012

0.36

1.26

0.02

0.002

8.16

18.28

0.058

[0045] The chemical composition of the 304L hot-rolled test coil with a specification of 4.0mm is shown in Table 3. The hot-rolled test coils are first annealed and pickled, then cold-rolled to 1.0mm after pickling, and then shot-peened and degreased and degreased after cold-rolling. min, the shot peening speed is 75m / s. 304L stainless steel was annealed for 20 minutes at 1150°C, normal pressure, and nitrogen-containing mixed atmosphere, and then water-cooled at a cooling rate of 4°C / s after annealing. The surface of the annealed austenitic stainless steel plate is ground to remove a 20 μm surface layer.

[0046] The microstructure observation and performance test were carried out on the 304L test roll sample (No. 30...

Embodiment 3

[0054] The cold working and annealing process of 304 austenitic stainless steel with a specification of 3.0mm is as follows: the hot-rolled test coil is annealed and pickled first, and then cold-rolled to 0.9mm after pickling. The shot size used in the shot is 0.05mm, the flow rate is 820kg / min, and the shot peening speed is 72m / s. Anneal 304 stainless steel for 10 minutes at 1200°C, normal pressure, and nitrogen-containing mixed atmosphere, and then water-cool at a rate of 6°C / S after annealing. The surface of the annealed austenitic stainless steel plate is ground to remove a 10 μm surface layer.

[0055] The thickness of the high nitrogen content surface layer formed on the surface of the stainless steel plate exceeds 60 μm, and its surface hardness is about HV 0.1 200. Pitting corrosion resistance E b100μA It reaches 460mV. Compared with the traditional industrial annealed board, the improvement range of various properties is between 10% and 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com