Method for improving uniformity of Al element in TC4 titanium alloy

A technology of uniform elements and titanium alloys is applied in the field of improving the uniformity of Al elements in TC4 titanium alloys, which can solve the problems of segregation of alloy elements, limiting the application of TC4 alloys, and low waste utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

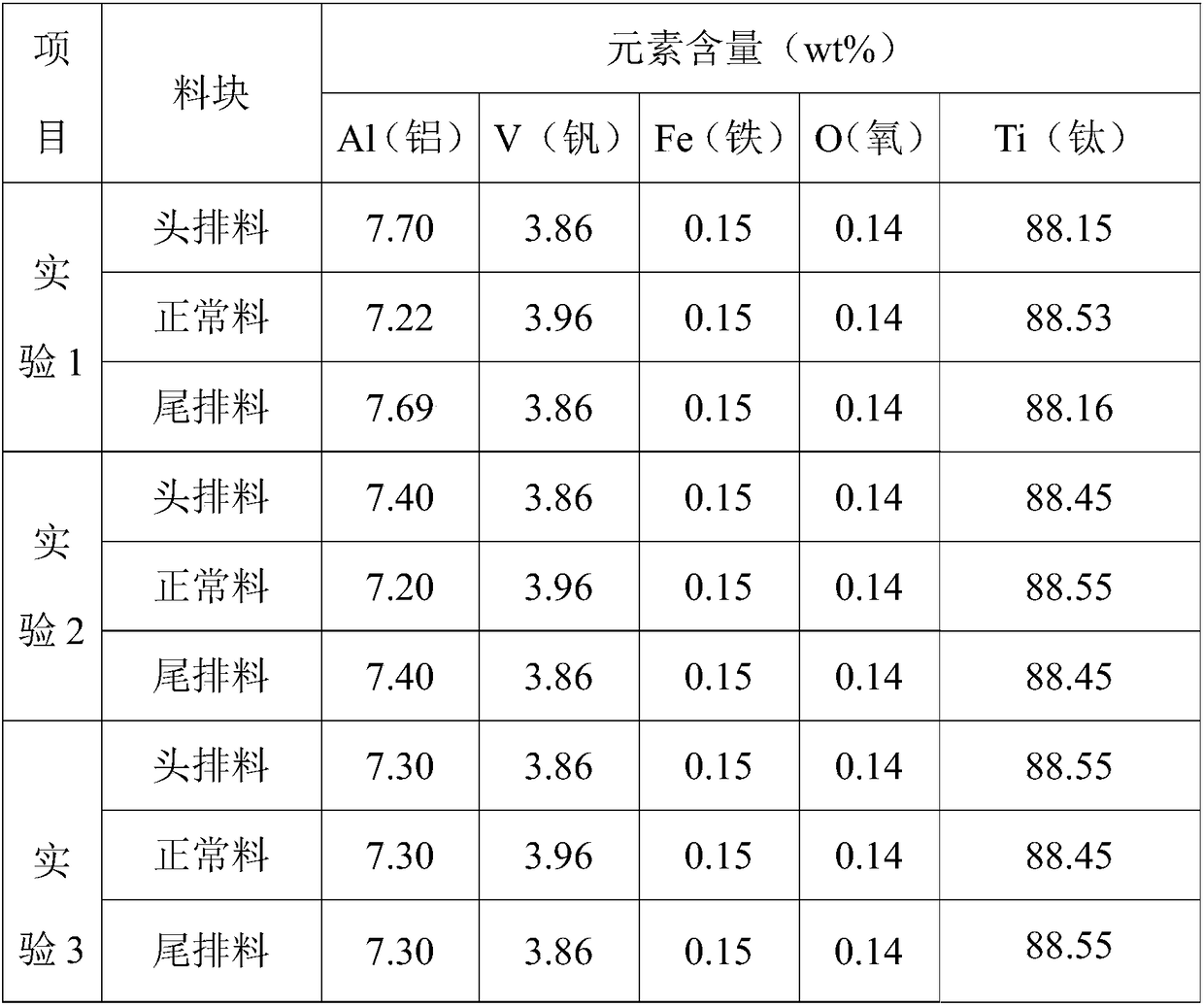

[0037] Example 1, the influence of the preparation of raw materials on the homogeneity of TC4 titanium alloy melted in one-time electron beam cooling hearth furnace

[0038] 1. Preparation of raw materials

[0039] The main factors affecting the uniformity of the chemical composition of the ingot tail are: the amount of alloying elements in the head discharge and the process parameters in the stage of starting the electron gun and the stage of making the bottom of the ingot. Let's consider the amount of ingredients first. In the stage of starting the electron gun, due to the unstable working conditions and the low melting speed at the end of the smelting stage, these all lead to a long time for the volatilization of Al elements to a large extent, and finally lead to a relatively low volatilization rate of Al elements. Large, the content at the tail of the ingot is low or even lower than the international standard, and the overall distribution of Al elements in the ingot is une...

Embodiment 2

[0073] Example 2, the influence of smelting process on the homogeneity of TC4 titanium alloy smelted in one-time electron beam cooling hearth furnace

[0074] The 3150KWB BMO-01 electron beam cooling hearth furnace uses a cold cathode electron gun. Since the cold cathode electron gun does not have a separate vacuum system, the inside of the entire gun body communicates with the melting chamber, and the gun body obtains vacuum through the melting chamber. When the vacuum degree of the smelting chamber reaches the requirement, the high-voltage power supply of the electron gun is turned on, and the working gas is introduced to start the electron gun. Hydrogen enters the gas ionization area of the electron gun shell from the inlet nozzle, and the gas is ionized under vacuum and high pressure conditions to generate H + , since the positive pole of the high voltage electron gun is connected to the anode, and the negative pole is connected to the cathode, so the ionized H + Under ...

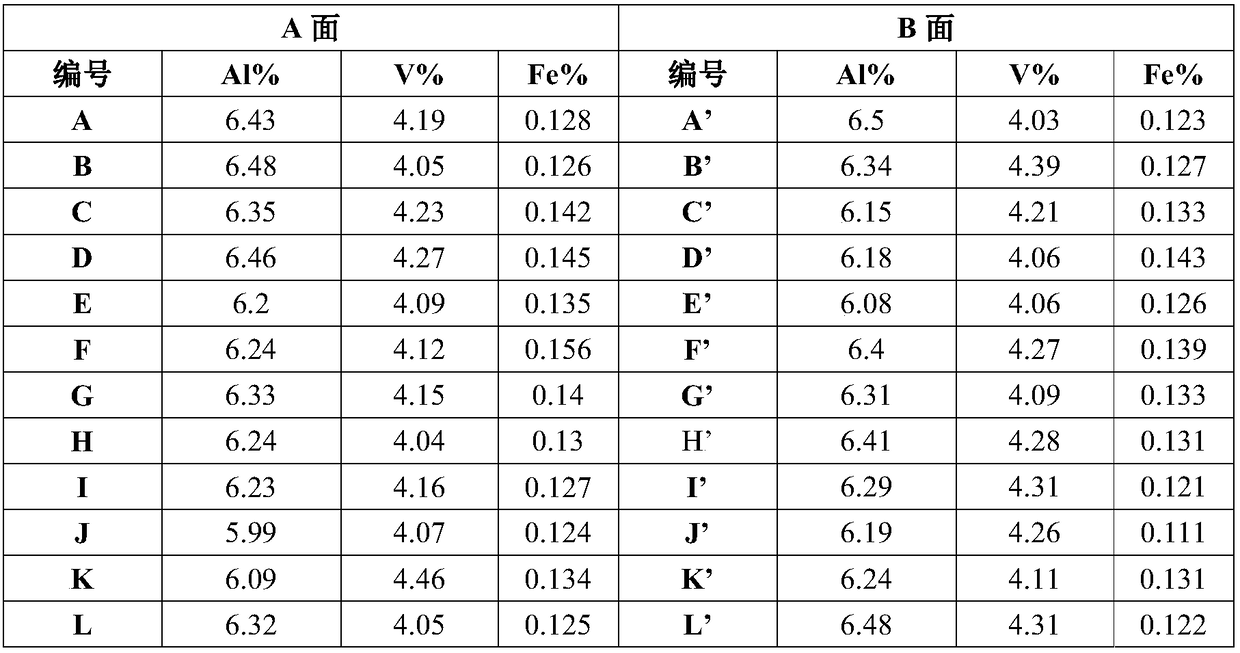

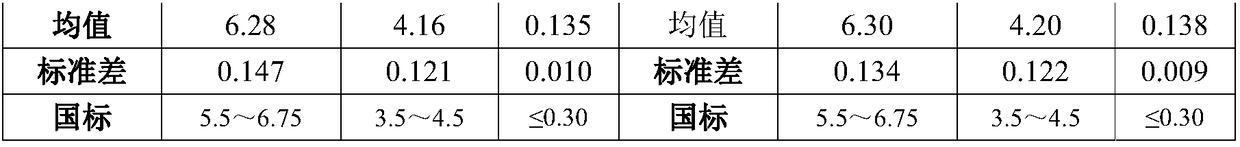

Embodiment 3

[0096] Example 3, the influence of smelting process on the uniformity of TC4 titanium alloy smelted in one-time electron beam cooling hearth furnace

[0097] The EB furnace smelting stage is the core link of EB furnace single smelting TC4 alloy, and it is the key link to control the volatilization of Al element. The volatilization of Al element is mainly related to the following two factors:

[0098] (1) Melting speed. If the smelting speed is too slow, it will take a long time to melt the entire ingot, and the time for Al volatilization will be long, and the volatilization rate will increase; if the smelting speed is too fast, the heat absorbed by the alloy liquid per unit time will increase, the volatilization speed of Al element will increase, and the volatilization rate will increase. The speed of smelting mainly depends on the total power of the 1~4# electron guns. When the smelting speed increases, the total feeding speed and the ingot pulling speed increase, and there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com