Apparatus for fabricating a III-V nitride film and a method for fabricating the same

a technology of nitride film and nitride film, which is applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas, etc., can solve the problem that the hvpe method cannot achieve good and stable properties, the aln film with poor crystallinity cannot be used for opto-electronic device substrates, and the hvpe method is not suitable for the above method. problem, to achieve the effect of reducing the cost of fabrica

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

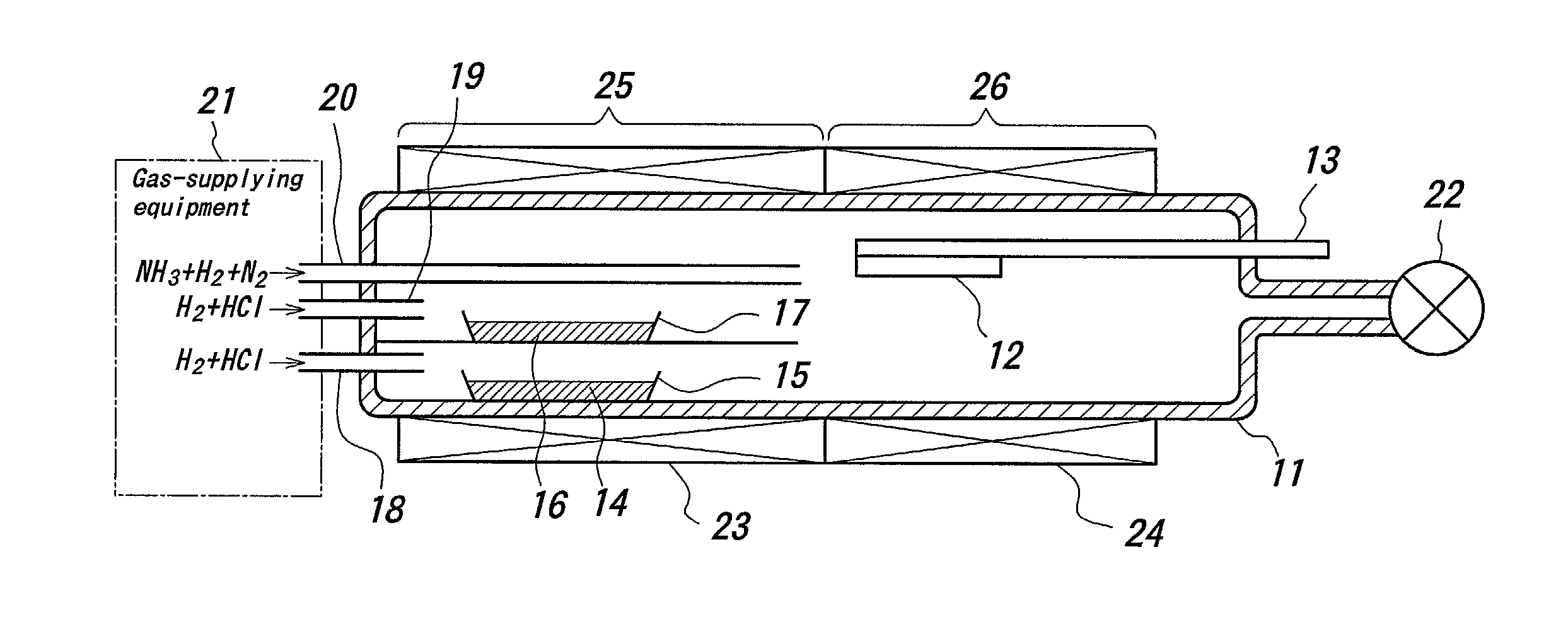

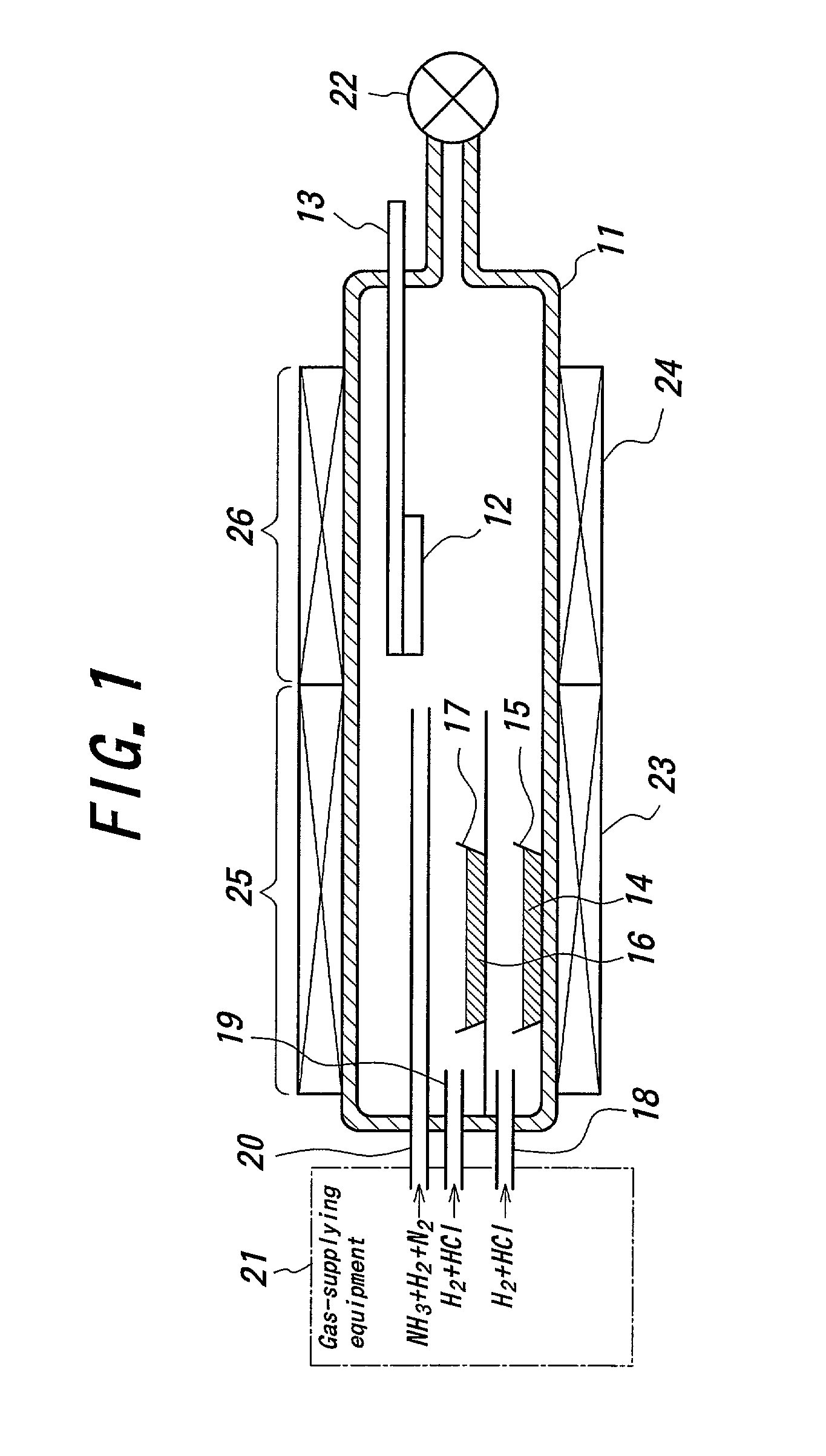

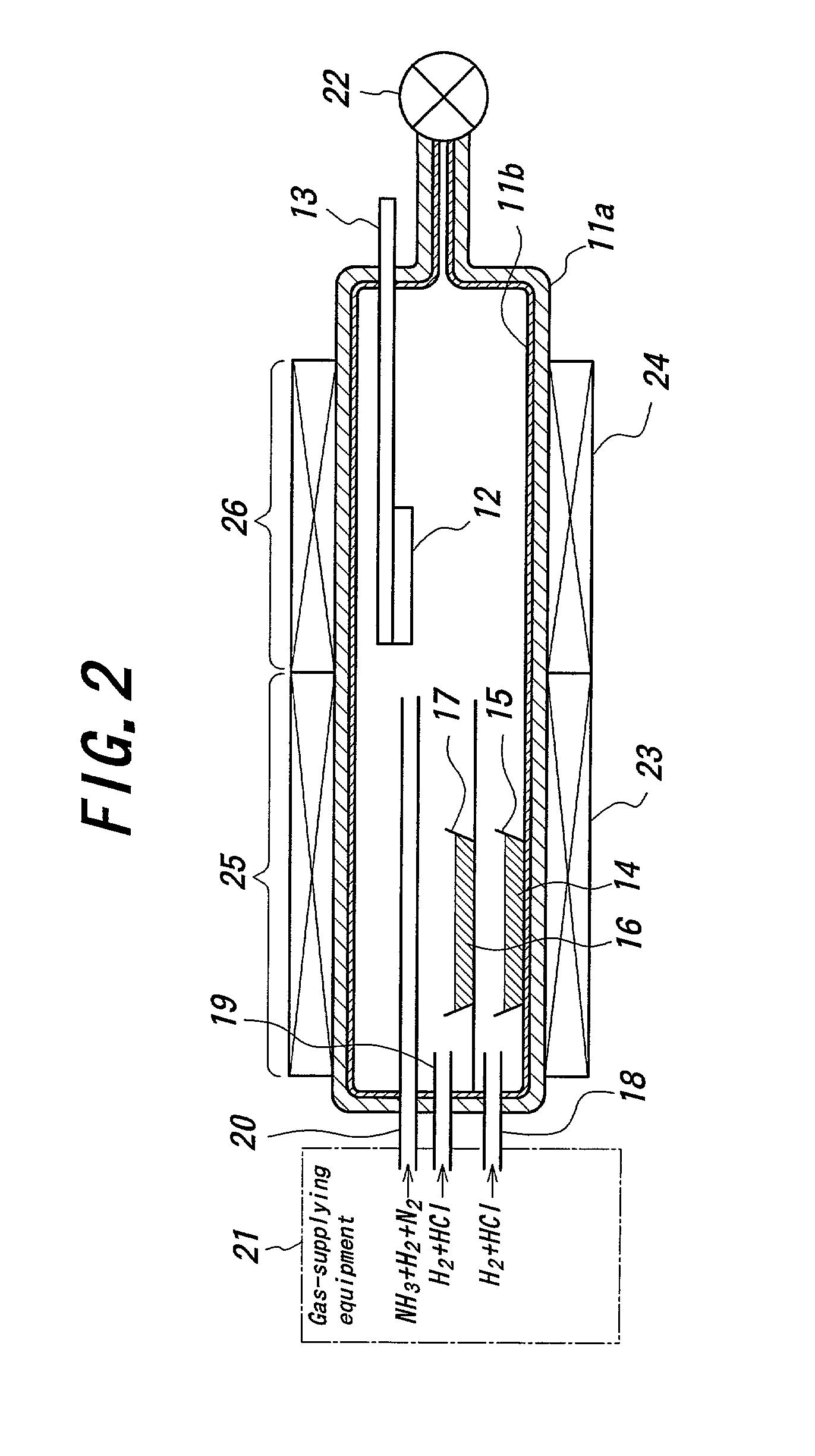

[0038]FIG. 1 is a structural view showing a first embodiment of the first fabricating apparatus of the present invention. In this embodiment, the whole of the reactor 11 is made of an aluminum nitride material not to be corroded by an AlCl gas. Herein, the wall thickness of the reactor 11 is exaggerated. The aluminum nitride material has a hexagonal or a cubic crystal structure, and may incorporate other elements up to 10% or so as impurities or additives.

[0039]Also, in this embodiment, an AlGaN film will be fabricated.

[0040]In the reactor 11 are arranged a susceptor 13 to hold a sapphire substrate 12 horizontally, a boat 15 to hold an aluminum metallic material 14 and a boat 17 to hold a gallium metallic material 16. In this embodiment, although the sapphire substrate 12 is held downward, it may be upward.

[0041]In this embodiment, a GaN underfilm is formed on the sapphire substrate 12 beforehand to complete an epitaxial growth substrate 12. For the sake of this, the boats 15 and 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Corrosion properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com