Si-Al-O-C ceramic material and preparation method thereof

A technology of ceramic materials and elements, applied in the field of high temperature resistant ceramic materials and their preparation, can solve the problems of unsuitable operating temperature conditions, loss of functional properties, decline in mechanical properties, etc., and achieves low equipment requirements, less mass loss, and thermal good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

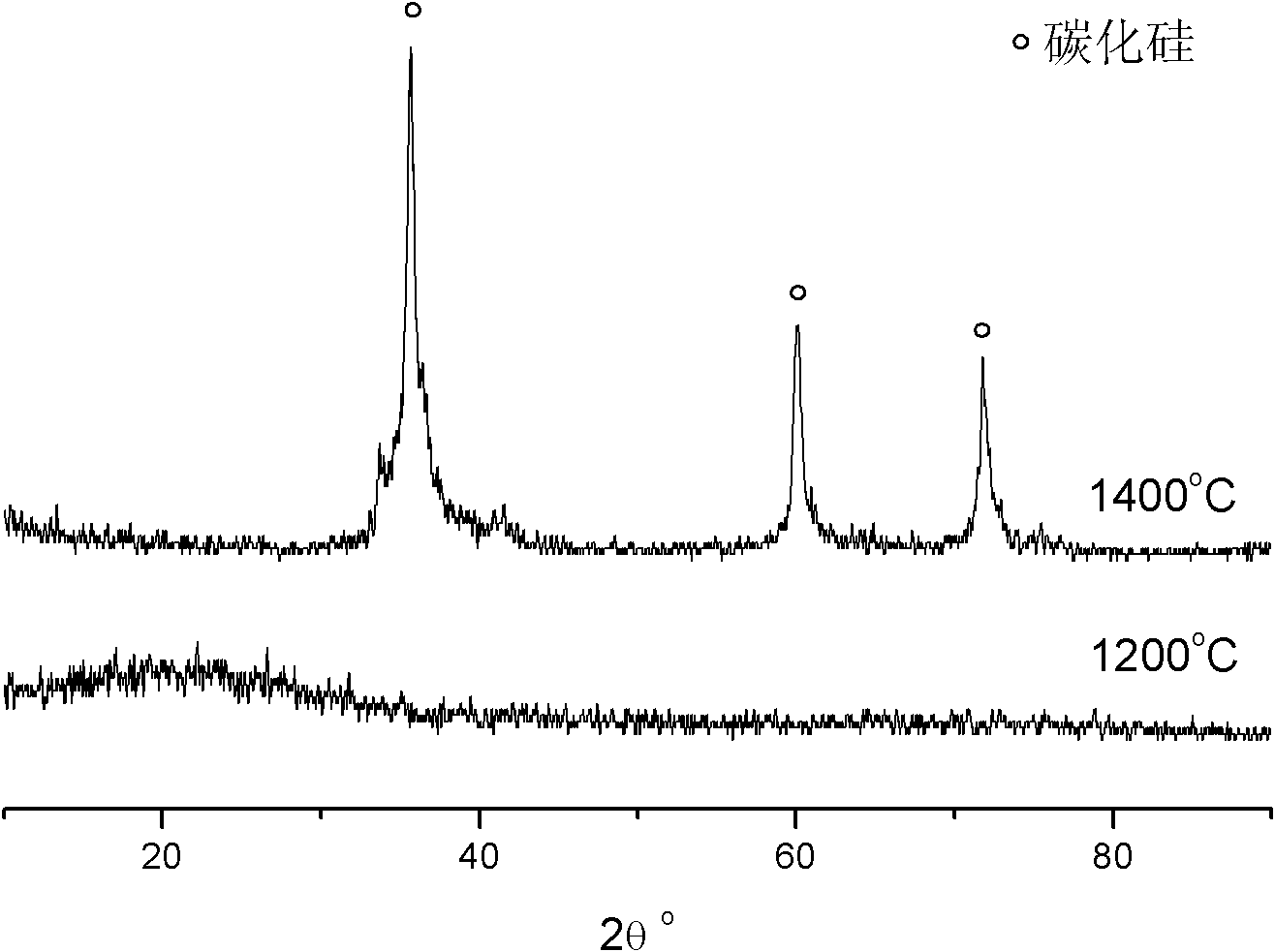

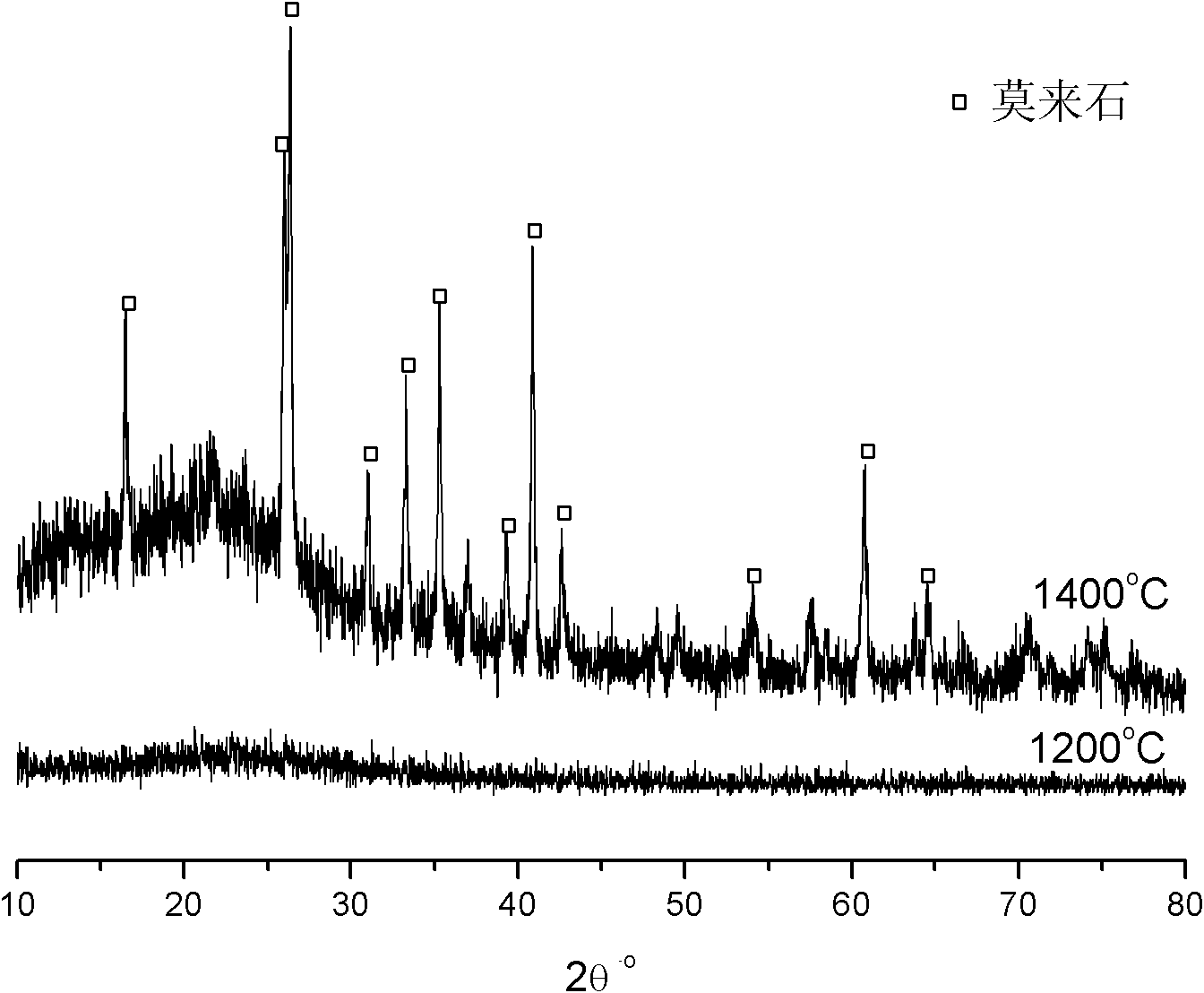

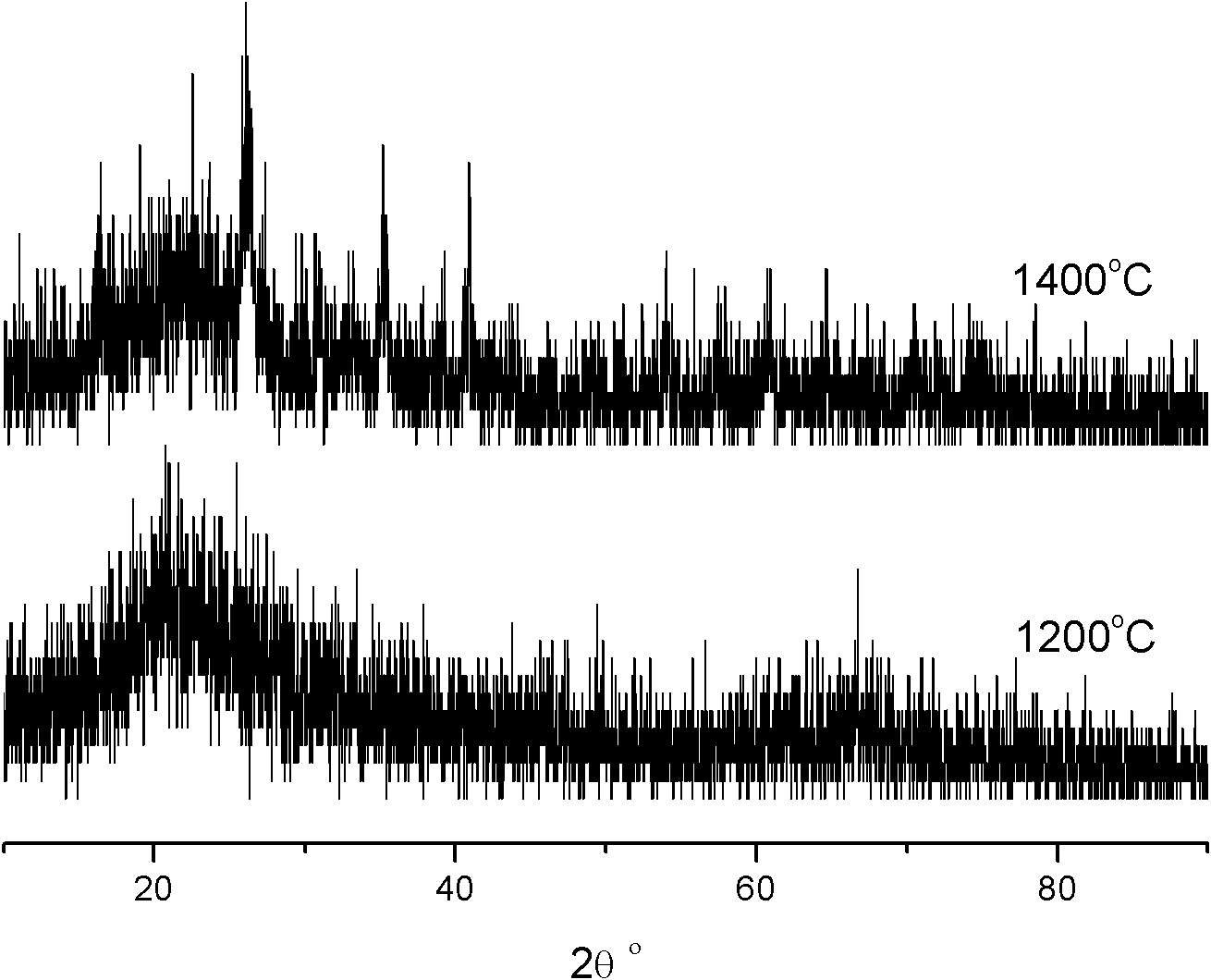

Image

Examples

Embodiment 1

[0029] The Si-Al-O-C ceramic material of this embodiment includes Si element, Al element, O element and C element, wherein, the mass fraction of Si element is 32%, the mass fraction of Al element is 14%, the mass fraction of O element is 24%, the mass fraction of C element is 30%, and its appearance is black. The Si-Al-O-C ceramic material is prepared through the following steps:

[0030] 1. Material preparation:

[0031] (1) At a constant temperature of 70°C, take aluminum chloride hexahydrate crystals (AlCl 3 ·6H 2 O) Dissolved in ethanol, wherein the content of aluminum is 10g / L, and an appropriate amount of urea is added thereto to obtain aluminum hydroxide precipitation, after washing with deionized water, it is ultrasonically peptized at a constant temperature at 80°C to prepare Aluminum hydroxide sol;

[0032] (2) preparing a mass concentration of 30% silicone resin ethanol solution containing Si-OH groups;

[0033] 2. Preparation of gel: Mix the prepared 30% silic...

Embodiment 2

[0038] The Si-Al-O-C ceramic material of this embodiment includes Si element, Al element, O element and C element, wherein, the mass fraction of Si element is 32%, the mass fraction of Al element is 14%, the mass fraction of O element is 24%, the mass fraction of C element is 30%, and its appearance is black. The Si-Al-O-C ceramic material is prepared through the following steps:

[0039] 1. Material preparation:

[0040] (1) Under constant temperature conditions of 70°C, aluminum sec-butoxide and deionized water are added to ethanol with a pH value of 3, and the volume ratio of aluminum sec-butoxide, deionized water and ethanol is 8:2:100, A light white transparent sol is formed, which is aluminum hydroxide sol;

[0041] (2) preparing a concentration of 30% silicone resin ethanol solution containing Si-OH groups;

[0042] 2. Preparation of gel: Mix the obtained 30% silicone resin ethanol solution and aluminum hydroxide sol according to the volume ratio of 1:5, and form a g...

Embodiment 3

[0047] The Si-Al-O-C ceramic material of this embodiment includes Si element, Al element, O element and C element, wherein, the mass fraction of Si element is 27%, the mass fraction of Al element is 28%, the mass fraction of O element is 20%, the mass fraction of C element is 25%, and its appearance is black. The Si-Al-O-C ceramic material is prepared through the following steps:

[0048] 1. Material preparation:

[0049] (1) Under constant temperature conditions of 70°C, aluminum sec-butoxide and deionized water are added to ethanol with a pH value of 3, and the volume ratio of aluminum sec-butoxide, deionized water and ethanol is 8:2:100, A light white transparent sol is formed, which is aluminum hydroxide sol;

[0050] (2) preparing a concentration of 15% silicone resin ethanol solution containing Si-OH groups;

[0051] 2. Preparation of gel: Mix the obtained 15% silicone resin ethanol solution and aluminum hydroxide sol according to the volume ratio of 1:5, and form a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com