Anti-oxidation MCrAlY fine-grain protective coating material and preparation method thereof

A protective coating and anti-oxidation technology, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problem of affecting the formation and growth of oxide film, restricting the wide application of coating technology, and the coating is easy to crack or Problems such as shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: In conjunction with the specific experimental process, describe in detail the implementation of the high-temperature oxidation resistance of CoCrAlY fine-grained protective coatings. Taking the same energy and different pulse times as examples, the specific steps are as follows:

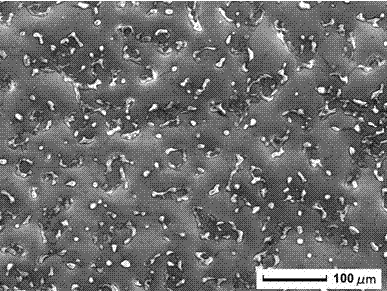

[0025] (1) Preparation of CoCrAlY fine-grain protective coating

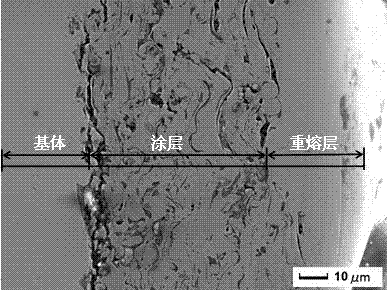

[0026] S1. The high-temperature alloy substrate, such as engine blades and other components, after pre-grinding, cleaning, and sandblasting roughening treatment, deposits a Co23Cr13Al0.5Y protective coating on the surface of the superalloy substrate by atmospheric plasma spraying, with a thickness of 200 μm; according to The technical requirements of the atmospheric plasma spraying equipment choose a voltage of 38 V, a current of 750 A, a spray gun speed of 450 mm / s, and a spraying distance of 85 mm.

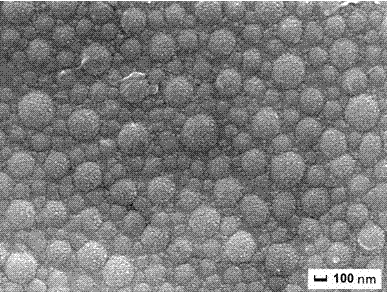

[0027] S2. Fix the prepared Co23Cr13Al0.5Y protective coating on the sample stage of the high-current pulsed electron...

Embodiment 2

[0034] Example 2: In conjunction with the specific experimental process, describe in detail the implementation of the high-temperature oxidation resistance of the Co23Cr13Al0.5Y fine-grained protective coating. Taking the same number of pulses and different energies as an example, the specific steps are as follows:

[0035] (1) Preparation of Co23Cr13Al0.5Y fine-grain protective coating

[0036] S1. After the superalloy substrate (or parts such as engine blades) has been pre-grinded, cleaned, and sandblasted, a Co23Cr13Al0.5Y protective coating is deposited on the superalloy substrate by atmospheric plasma spraying, with a thickness of 200 μm; according to the atmosphere The technical requirements of the plasma spraying equipment choose a voltage of 38 V, a current of 750 A, a spray gun speed of 450 mm / s, and a spraying distance of 85 mm.

[0037] S2. Fix the prepared Co23Cr13Al0.5Y protective coating on the sample stage of the high-current pulsed electron beam (HCPEB) device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com