Preparation method for precious metal and transition metal nanowires and nano reticular material

A technology of transition metals and mesh materials, applied in metal material coating technology, material analysis through optical means, nanotechnology, etc., can solve the problems of complex product separation process and difficult control of reaction process, and achieve a wide range of components , short production cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

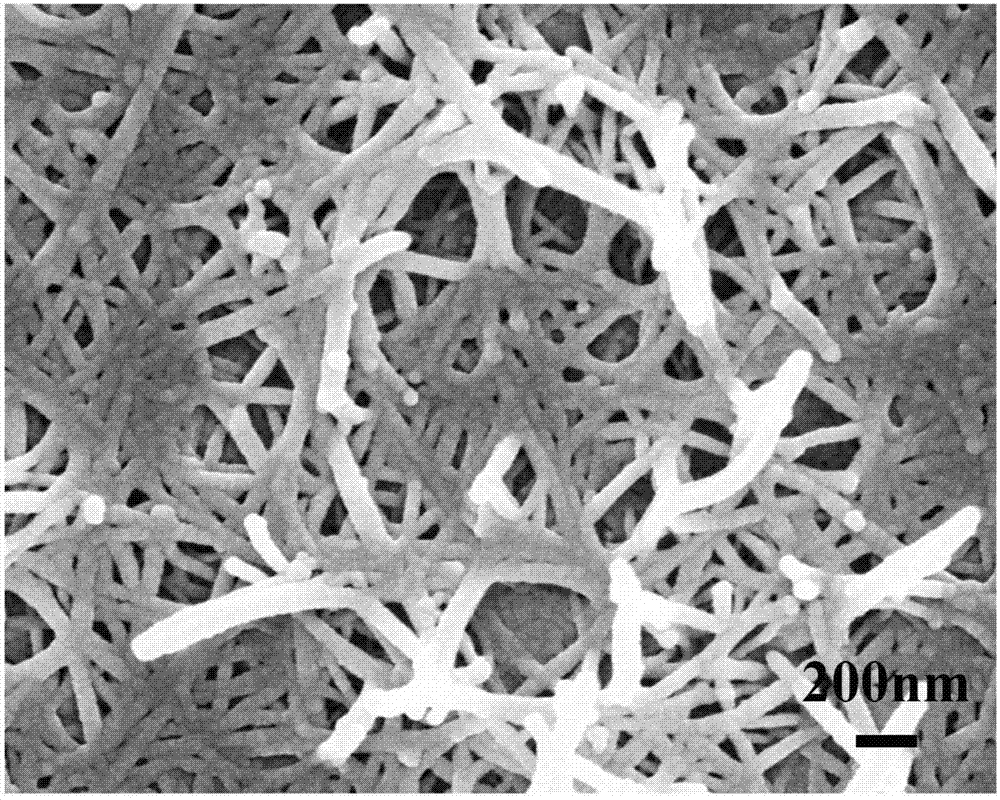

[0024] (1) with Cu 30 Zr 60 al 5 Ag 5 As the nominal composition of the initial alloy, the pure elements required for the initial alloy (Cu>99.9999wt%, Zr>99.9wt%, Al>99.999wt%, Ag>99.99wt%) are converted into mass (10g ) and weighed respectively, and then placed in a high-vacuum electric arc furnace to vacuum the cavity to 10 -4 Below Mpa, and filled with high-purity argon (>99.9wt%).

[0025] (2) Use high vacuum arc melting equipment to pair the prepared Cu 30 Zr 60 al 5 Ag 5 The initial alloy constituent materials are melted.

[0026] (3) Remove Cu from the surface scale 30 Zr 60 al 5 Ag 5The initial alloy ingot is re-melted by induction heating in the quartz tube, and is continuously and rapidly sprayed onto the water-cooled copper roller (the diameter of the copper roller is 220mm, and the rotation speed is 3000r / min) under the action of high-purity argon gas with a pressure of about 0.2MPa to form a width 1-2mm, Cu with a thickness of about 20μm 30 Zr 60 A...

Embodiment 2

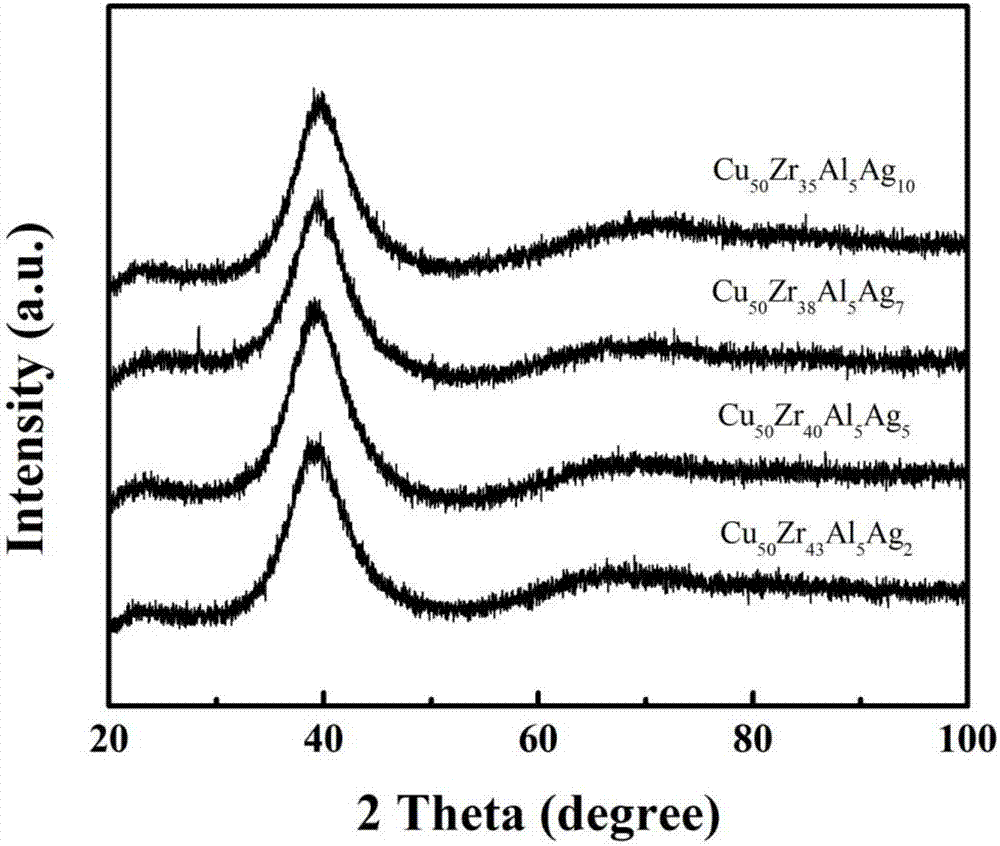

[0031] (1) with Cu 50 Zr 45-x Al 5 Ag x (x=2, 5, 7, 10, x is the atomic percentage) as the initial alloy, the pure elements required for the initial alloy (Cu>99.9999wt%, Zr>99.9wt%, Al>99.999wt%, Ag>99.99 wt%), converted into mass (10g) according to the atomic percentage of the alloy and weighed respectively, and then placed in a high-vacuum electric arc furnace to vacuum the cavity to 10 -4 Below Mpa, and filled with high-purity argon (>99.9wt%).

[0032] (2) Use high vacuum electric arc furnace melting equipment to pair the prepared Cu 50 Zr 45-x Al 5 Ag x (x = 2, 5, 7, 10) initial alloy constituent materials are melted.

[0033] (3) Remove Cu from the surface scale 50 Zr 45-x Al 5 Ag x (x=2, 5, 7, 10) The initial alloy ingot is re-melted by induction heating in the quartz tube, and is continuously and rapidly sprayed onto the water-cooled rotating copper roller under the action of high-purity argon with a pressure of about 0.2MPa (copper roller diameter 220mm,...

Embodiment 3

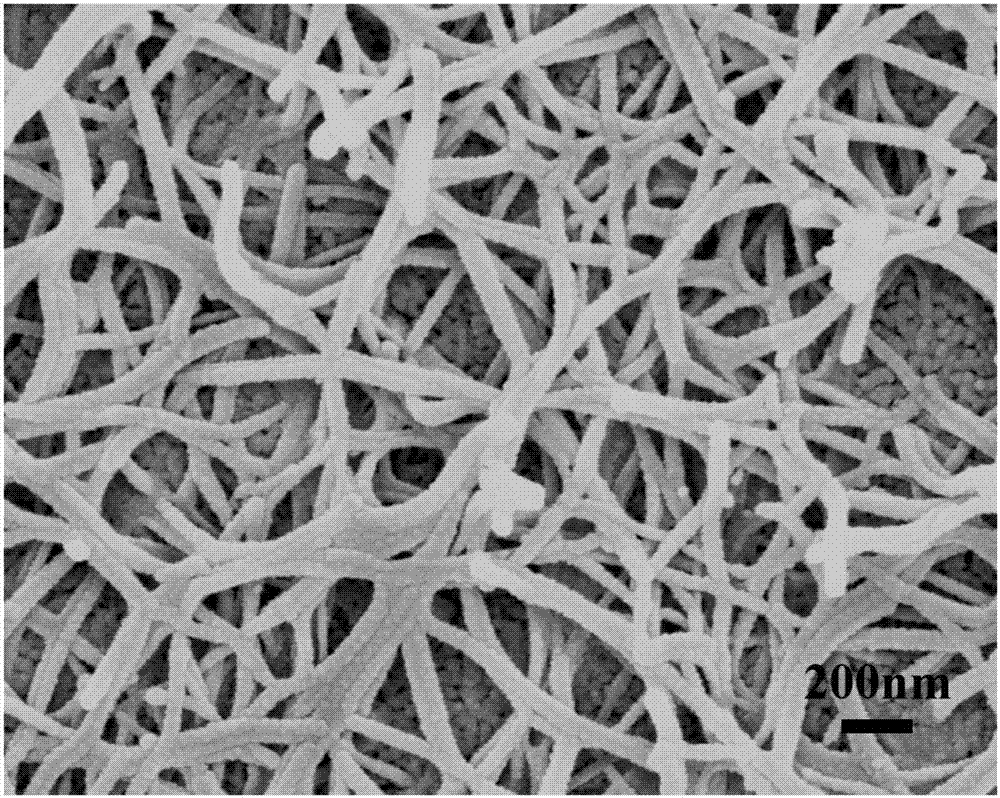

[0039] (1) with Cu 30 Zr 60 Al 5 Ag 5 As the nominal composition of the initial alloy, the pure elements required for the initial alloy (Cu>99.9999wt%, Zr>99.9wt%, Al>99.999wt%, Ag>99.99wt%) are converted into mass (10g ) and weighed respectively, and then placed in a vacuum induction arc furnace, and the cavity was vacuumed to 10 -4 Below Mpa, and filled with high-purity argon (>99.9wt%).

[0040] (2) Use high vacuum electric arc furnace melting equipment to pair the prepared Cu 30 Zr 60 Al 5 Ag 5 The initial alloy constituent materials are melted.

[0041] (3) Remove Cu from the surface scale 30 Zr 60 Al 5 Ag 5 The initial alloy ingot is re-melted by induction heating in the quartz tube, and is continuously and rapidly sprayed onto the water-cooled rotating copper roller (the diameter of the copper roller is 220mm, and the rotation speed is 3000r / min) under the action of high-purity argon gas with a pressure of about 0.2MPa, forming a width of 1 -2mm, Cu with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com