Surface composite coated anode material, preparation method thereof and lithium ion battery

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of positive electrode material structure damage, safety accidents, and high temperature cycle performance to be improved, and achieve excellent high temperature cycle performance and rate performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

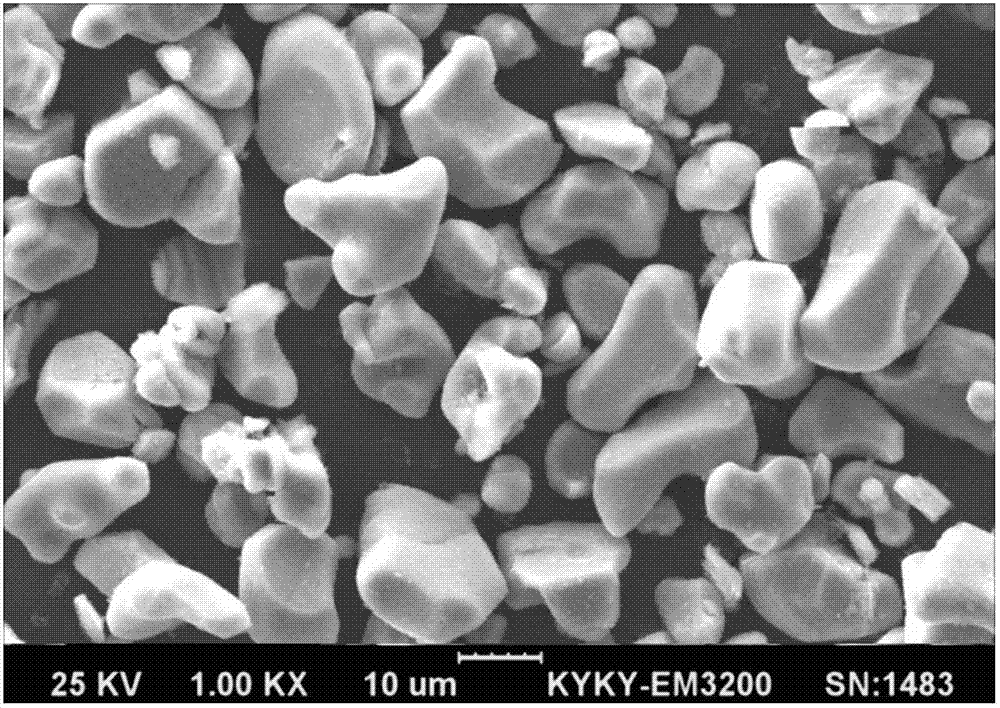

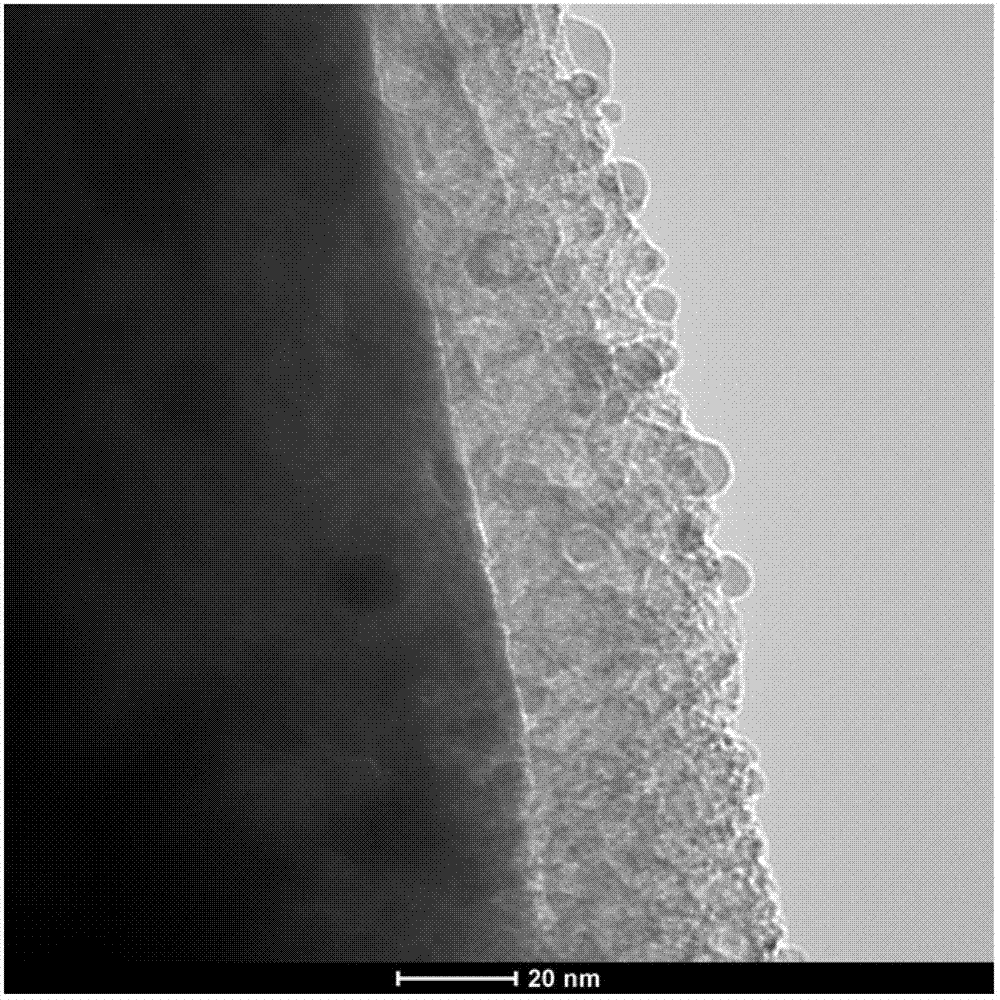

Embodiment 1

[0037] Weigh 2.09g Al(NO 3 ) 3 9H 2 O was dissolved in 20mL water; weighed 0.45g NaOH and 0.21g (NH 4 ) 2 HPO 4 , mixed, dissolved in 20mL of water; NaOH and (NH 4 ) 2 HPO 4 The resulting solution was slowly added dropwise to Al(NO 3 ) 3 9H 2In the O solution, control the pH at 4.5 to obtain a sol; weigh 200g of a layered lithium intercalation compound lithium cobaltate sample, add 120mL of water as a dispersion medium, and stir and disperse; slowly add the formed sol to the stirred and dispersed lithium cobaltate In the sample, react for 2 hours; stand still, filter, and dry the obtained filter cake; roast the dried material at 550°C for 5 hours to obtain Al 2 o 3 -AlPO 4 Composite coated lithium cobalt oxide cathode material, wherein the mass percentage of Al element and lithium cobalt oxide is 0.075%; 2 o 3 -AlPO 4 Al in composite layer 2 o 3 The mass ratio fraction that accounts for is 51.14%.

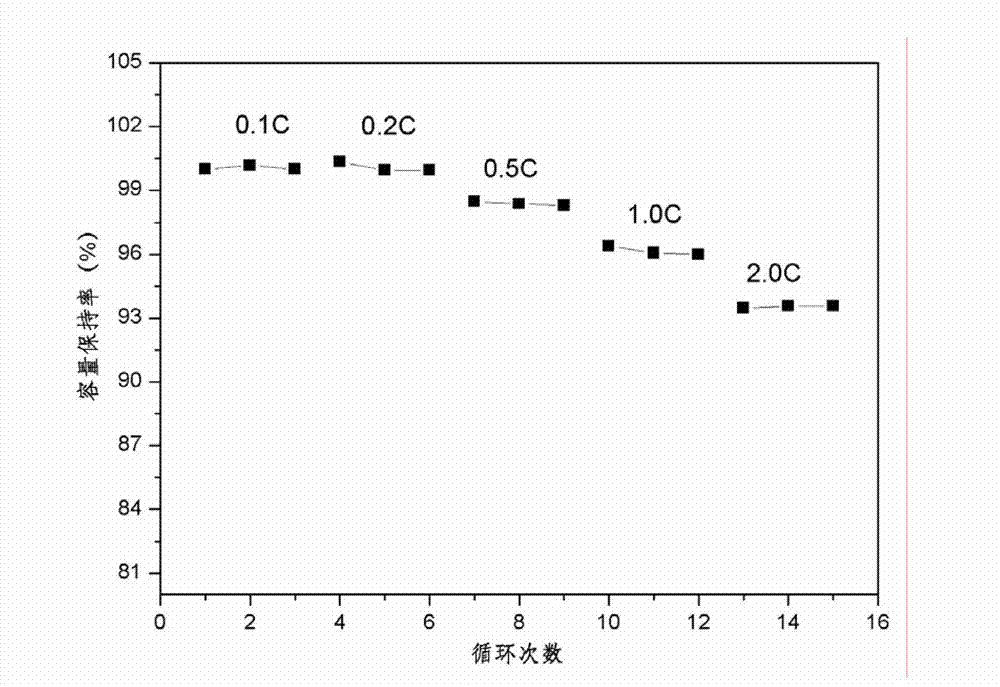

[0038] Al 2 o 3 -AlPO 4 Composite-coated lithium cobalt o...

Embodiment 2

[0041] Weigh 1.65g Al 2 (SO4) 3 Dissolve in 20mL water; weigh 0.55g KOH and 0.19g (NH 4 ) 2 HPO 4 , mixed, dissolved in 20mL of water; KOH and (NH 4 ) 2 HPO 4 The resulting solution was slowly added dropwise to the Al 2 (SO4) 3 In the solution, control the pH at 7.0 to obtain a sol; weigh 200g of a layered lithium intercalation compound lithium cobaltate sample, add 120mL of water as a dispersion medium, and stir and disperse; add the formed sol dropwise to the stirred and dispersed lithium cobaltate sample , reacted for 2 hours; stood still, filtered, and dried the obtained filter cake; roasted the dried material at 650°C for 5 hours to obtain Al 2 o 3 -AlPO 4 Composite-coated lithium cobalt oxide cathode material, wherein the mass percentage of Al element and lithium cobalt oxide is 0.065%, in Al 2 o 3 -AlPO 4 Al in composite layer 2 o 3 The mass ratio fraction that accounts for is 70%.

[0042] Al prepared by 2 o 3 -AlPO 4 The composite coated lithium cob...

Embodiment 3

[0047] Weigh 2.03g Al 2 (SO 4 ) 3 Dissolve in 20mL water; weigh 0.67g KOH and 0.45g K 2 HPO 4 , mixed, dissolved in 20mL of water; KOH and K 2 HPO 4 The resulting solution was slowly added dropwise to the Al 2 (SO 4 ) 3 In the solution, control the pH at 4.8 to obtain a sol; weigh 200g of layered lithium intercalation compound Li(Ni 0.5 co 0.2 mn 0.3 )O 2 For battery cathode material, add 120mL water as the dispersion medium, and stir and disperse; add the formed sol dropwise to the stirred and dispersed lithium cobalt oxide sample, and react for 3 hours; let stand, filter, and dry the obtained filter cake; dry The material was calcined at 800°C for 5h to obtain Al 2 o 3 -AlPO 4 Composite coated Li(Ni 0.5 co 0.2 mn 0.3 )O 2 Lithium-ion battery cathode material, in which Al element and lithium intercalation compound Li(Ni 0.5 co 0.2 mn 0.3 )O 2 The mass percentage is 0.080%, in Al 2 o 3 -AlPO 4 Al in composite layer 2 o 3 The mass ratio fraction that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com