Codeposition gradient Ni-base superalloy coating and preparation technique thereof

A preparation process, gradient coating technology, applied in the direction of metal material coating process, coating, layered products, etc., can solve the problems of unfavorable coating parts alternating cold and hot cycle work, increase of coating brittleness, etc., and achieve service life Long, delay coating degradation, prolong the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

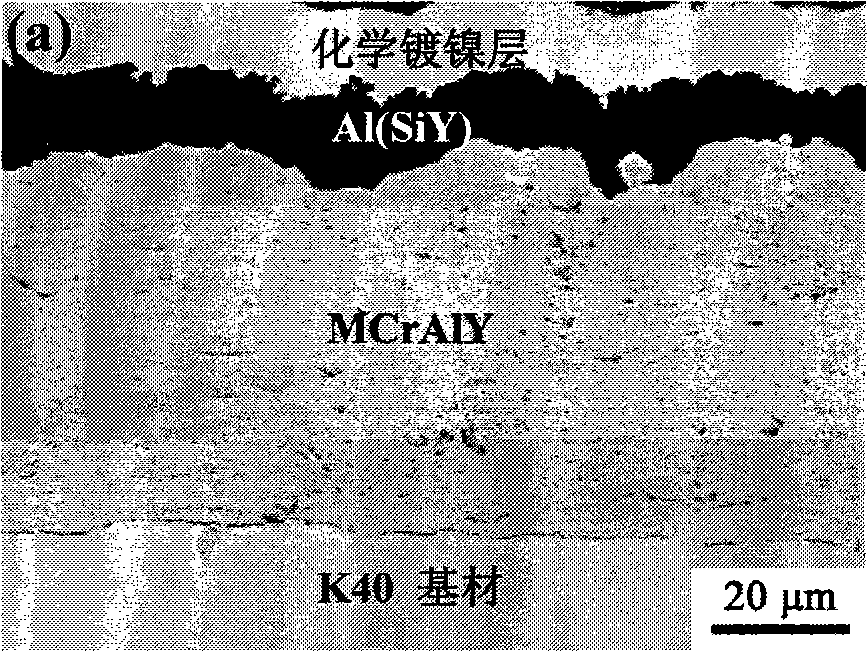

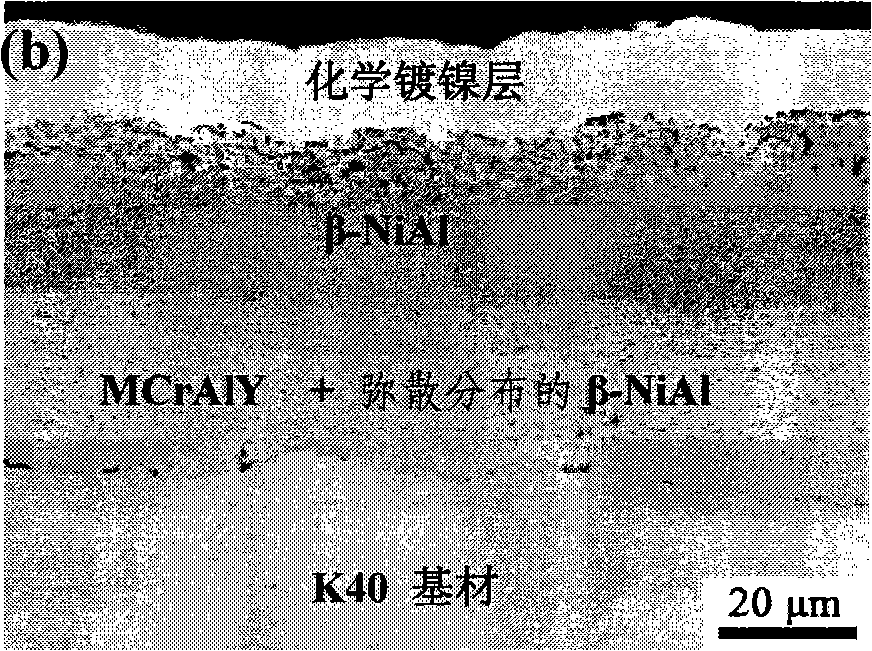

Embodiment 1

[0023] The base material is Co-based superalloy K40, and its nominal composition is (mass percentage): 10.5% Ni, 25.5% Cr, 7.5% W, 0.45% C, Co balance, and the sample size is 15×10×1.5mm 3 . The MCrAlY+Al(SiY) composite coating was co-deposited by domestic MIP-8-800 multi-arc ion plating equipment. The composition of the MCrAlY target is as follows (by mass percentage), Co: 32; Cr: 20; Al: 8; Y: 0.5; Si: 1; B: 0.03, Ni: the balance. The sample is pretreated before deposition, that is, the substrate sample is polished to Ra=0.4 μm, wet sandblasting with 200-mesh hollow glass pellets, and then ultrasonically cleaned with metal detergent, deionized water, and acetone for 15 minutes, and washed with alcohol Rinse and tumble dry for later use. MIP-8-800 arc ion plating equipment was used to deposit conventional MCrAlY coatings, pre-evacuated to 7×10 -3 Pa, Ar gas was introduced during bombardment and deposition, and the vacuum degree was 2×10 -1 Pa. Clean the sample by pre-spu...

Embodiment 2

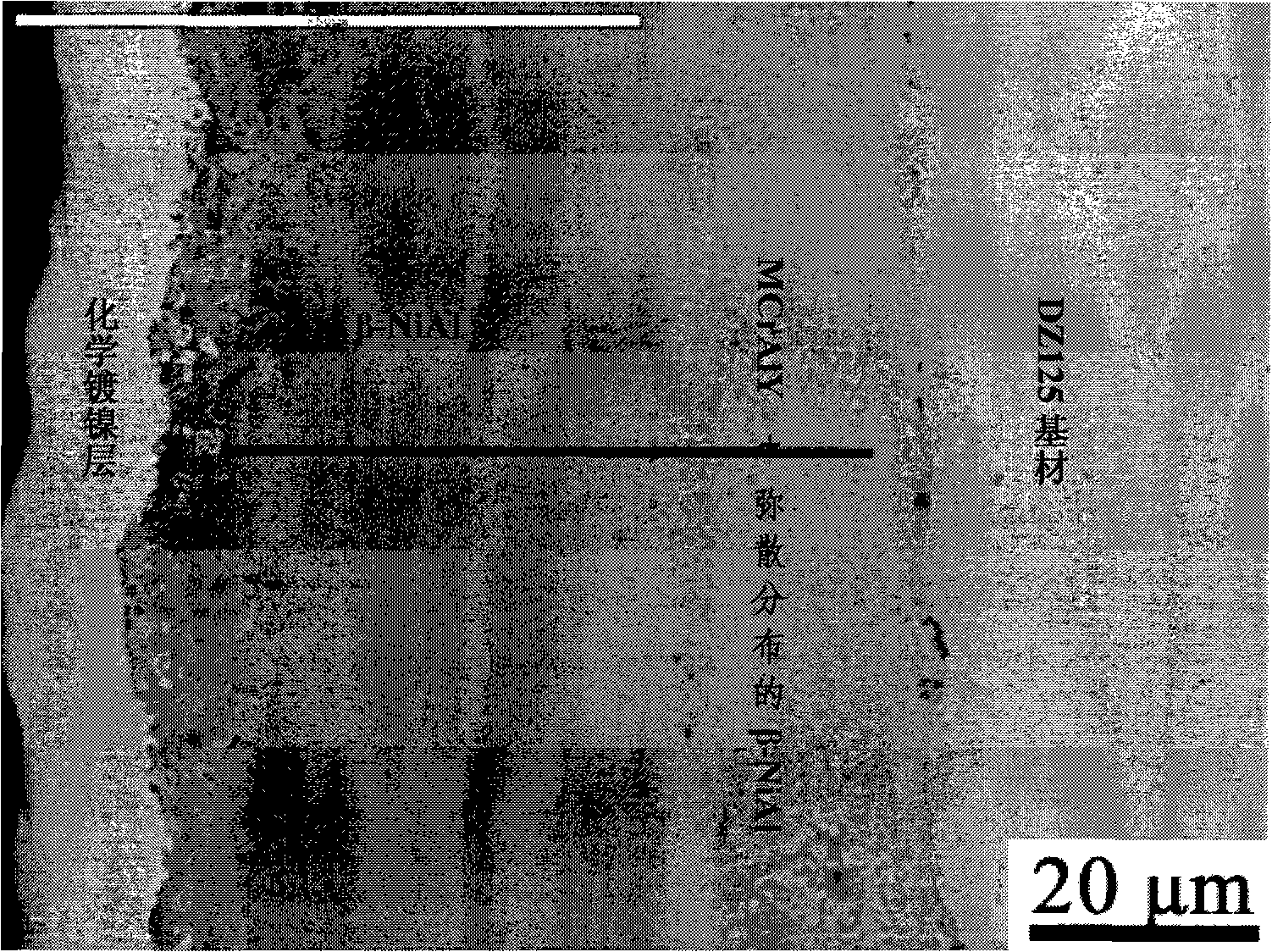

[0027] The base material is directionally solidified Ni-based superalloy DZ 125, and its nominal composition is (by mass percentage): 10% Co, 9% Cr, 7% W, 5% Al, 2.5% Ti, 3.5% Ta, trace amounts of C, Ni margin. The conventional MCrAlY coating process by arc ion plating is the same as in Example 1, and the thickness of the obtained conventional MCrAlY coating is about 60 μm. Continue to co-deposit pure Al coating on the obtained conventional MCrAlY coating, the deposition process is basically the same as that of ordinary MCrAlY coating, the pulse bias is -200V, and the thickness of the obtained pure aluminum coating is about 12 μm.

[0028] Put the MCrAlY co-deposition coating sample coated with pure Al coating into the air pressure less than 1×10 -2 In a Pa vacuum furnace, the temperature was raised to 1000°C at a heating rate of 7°C / min, held for 5 hours, and cooled to room temperature with the furnace to obtain a co-deposited gradient MCrAlY coating with a thicker outer alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com