High-strength container plate with excellent low-temperature toughness and manufacturing method

A low-temperature toughness and manufacturing method technology, applied in the field of steel production, to achieve the effect of increasing strength, improving low-temperature toughness and strength, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

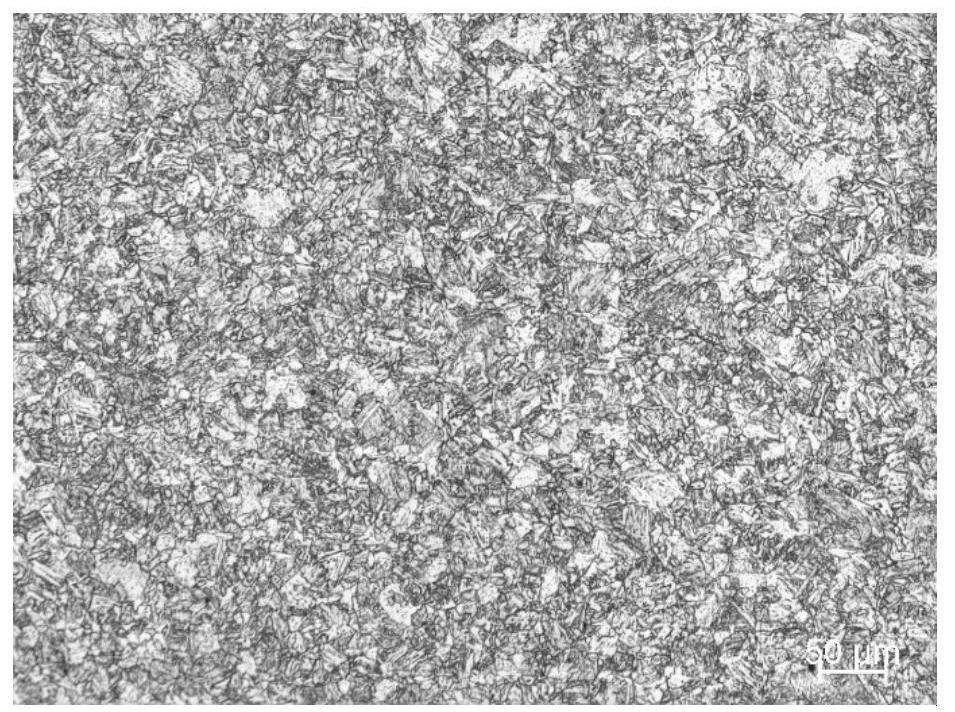

Image

Examples

Embodiment Construction

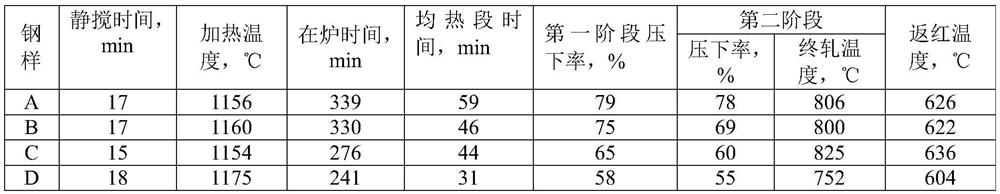

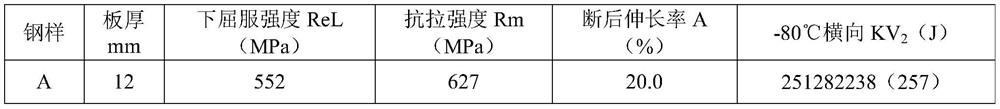

[0030] The following examples provide a high-strength container plate with excellent low-temperature toughness and its manufacturing method. The chemical composition is shown in Table 1, the smelting and rolling process parameters are shown in Table 2, and the heat treatment process parameters are shown in Table 3. Specifically The steps are:

[0031] Steelmaking and continuous casting: steelmaking and continuous casting: pretreatment of molten iron, S content in molten iron < 0.002wt%, converter steelmaking, deep desulfurization and deoxidation in LF furnace, adjustment of alloy composition to the target range and superheat control, RH furnace desulfurization Gas, vacuum degree ≤0.3torr, RH refining, feeding pure calcium wire for calcium treatment, static stirring time after feeding wire ≥15min, continuous continuous casting into 260mm thick billet, casting billet for stack cooling treatment, stack cooling time ≥48 hours;

[0032] Slab heating: the slab is heated to 1130-1160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com