Hydraulic support cap

A technology of hydraulic supports and column caps, which is applied in the direction of mine roof supports, pillars/supports, mining equipment, etc., can solve the problems of low strength, poor safety and reliability, and easy damage, and achieve increased strength, safety and use The effect of prolonging the life and satisfying the conditions of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

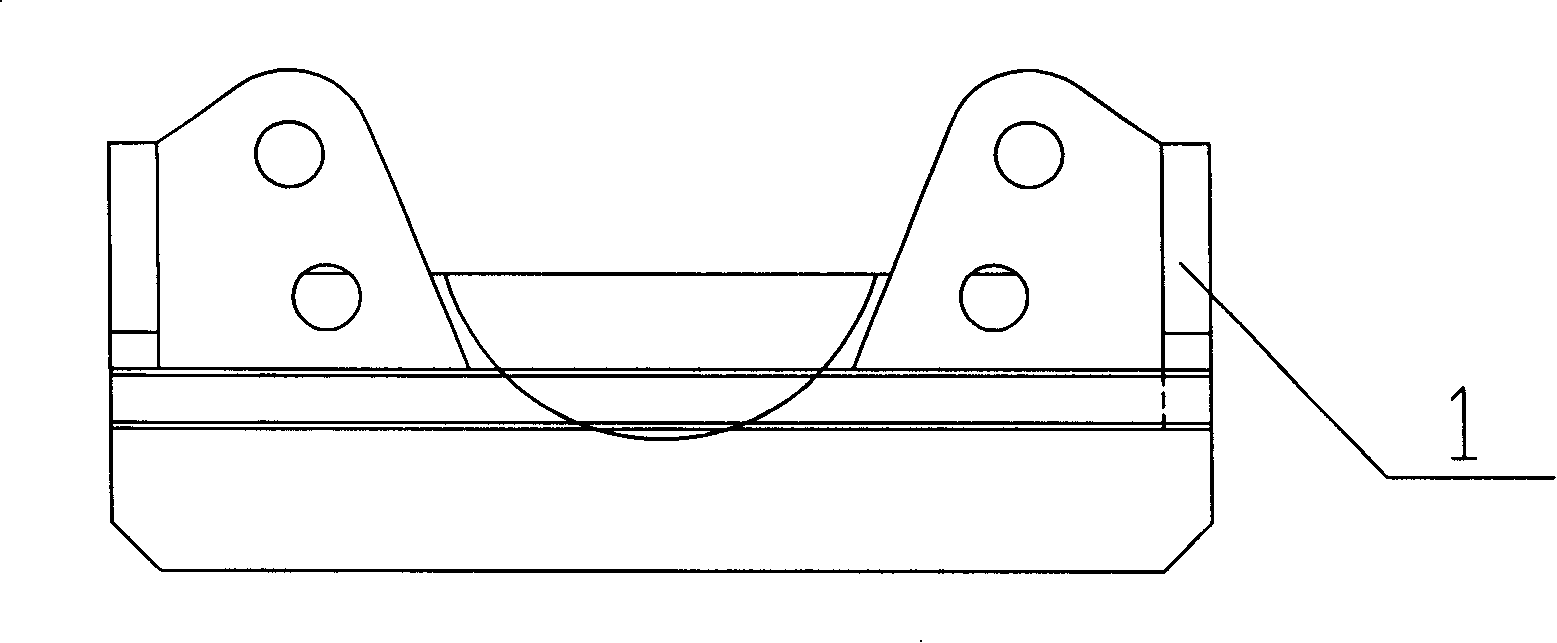

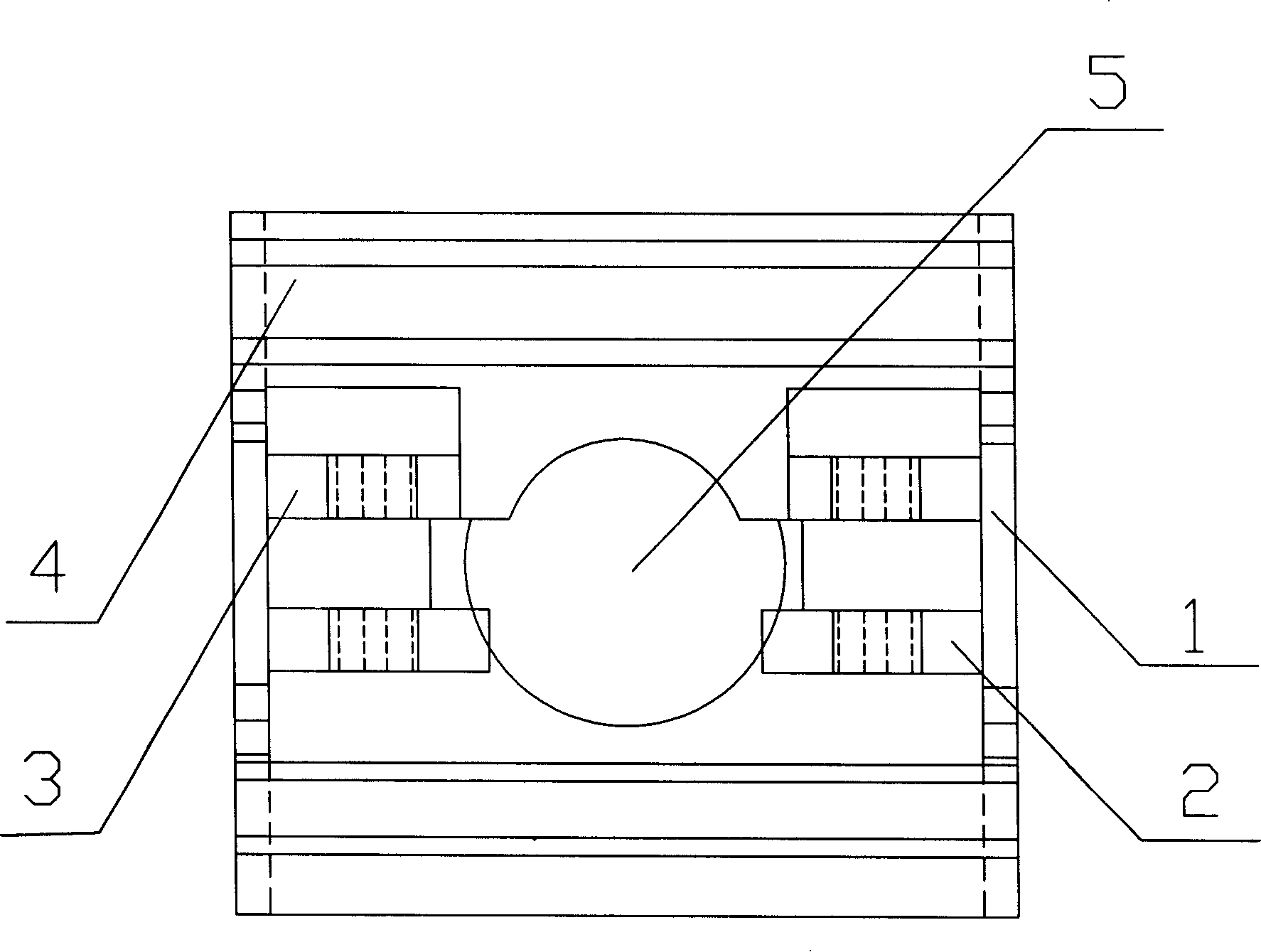

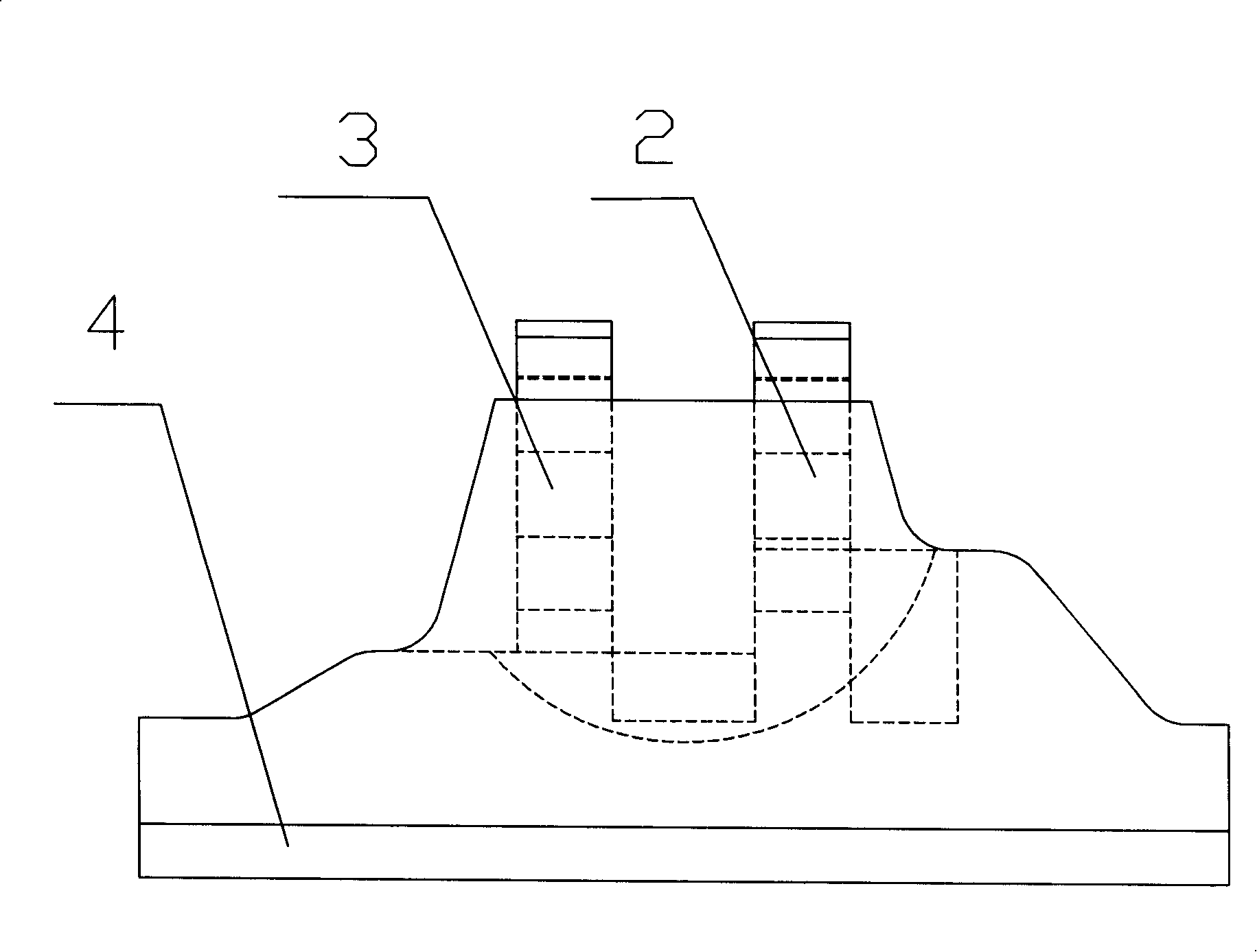

[0018] Example 1: Such as figure 1 , figure 2 , image 3 As shown, the hydraulic support column cap includes a column cap body 4 integrally forged from alloy structural steel with a yield point of 800 MPa, and an ear plate 1, an ear plate 2, 3, and a side plate 1 welded to it, respectively. 2. Ear plate 2 3 and side plate 1 are respectively processed from alloy steel plates with a yield point of 500MPa.

[0019] The present embodiment adopting the above-mentioned structure improves the manufacturing efficiency, increases the strength and the service life, thereby has a high safety factor and is easy to popularize.

Embodiment 2

[0020] Example 2: The basic structure is the same as that of Example 1. The yield point value of the alloy structural steel used in the column cap body 4 is 810MPa, and the yield point value of the alloy steel plate used in the ear plate 1, the ear plate 2 3 and the side plate 1 530MPa.

Embodiment 3

[0021] Example 3: The basic structure is the same as that of Example 1. The yield point value of the alloy structural steel used in the column cap body 4 is 830 MPa, and the yield point value of the alloy steel plate used in the ear plate 1, the ear plate 2 3 and the side plate 1 is 550MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com