Steel for high-strength wear-resisting type ball grinder steel balls and preparation method thereof

A kind of wear-resistant ball mill technology, which is applied in the field of iron and steel smelting, can solve the problems of narrow application range of ball mill steel balls, affecting grinding and peeling ability, and surface wear of steel balls, so as to enhance wear resistance, impact resistance and friction resistance. , good rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

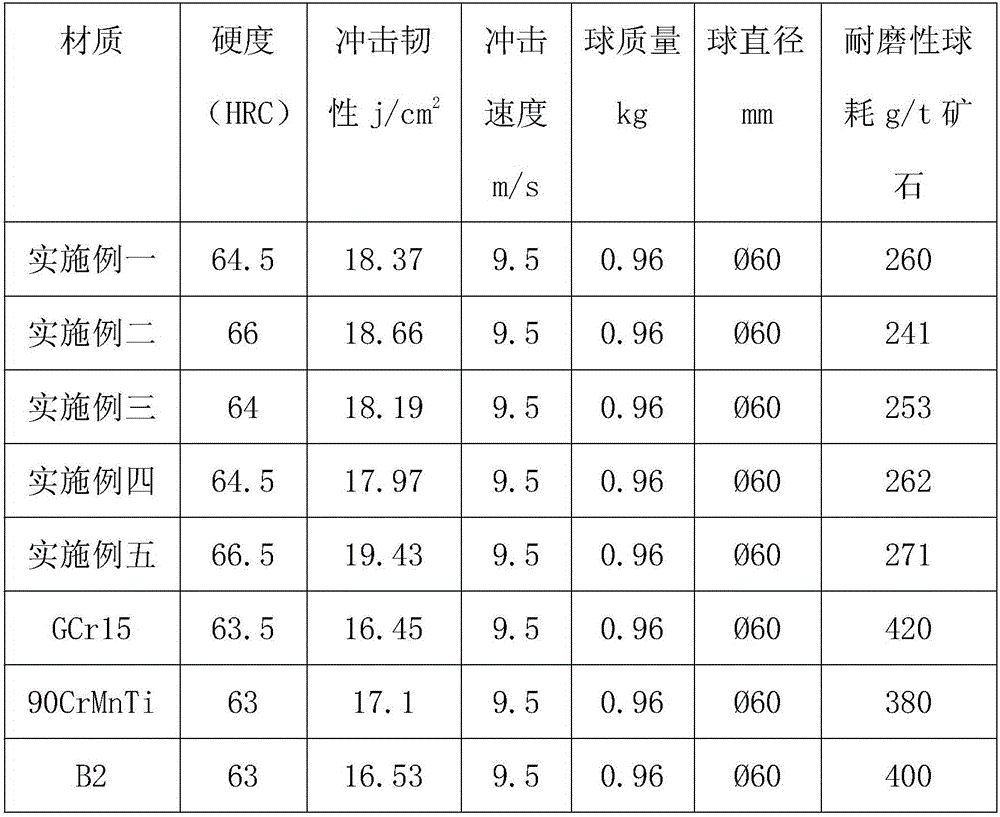

Examples

Embodiment 1

[0018] The high-strength wear-resistant ball mill steel ball proposed by the present invention includes the following components in weight percentage: C 0.95%, Si 0.3%, Mn 0.95%, Cr 1.2%, W 0.19%, Ti 0.08%, P 0.01% , S 0.02%, the balance is Fe and a small amount of impurities.

[0019] Its preparation method comprises the following steps:

[0020] S1: Smelting, smelting, heating the temperature of the smelting furnace to 1700°C, and adding W, Fe, Cr and Ti with corresponding specific gravity into the smelting furnace for smelting, after all melting, the smelting molten steel is obtained;

[0021] S2: Refining, transfer the above molten steel to a refining furnace at a temperature of 1480°C, add C, Si, Mn, P and S with corresponding specific gravity, and add hexachloroethane at the same time for preliminary refining, and then the preliminary refining The molten steel is subjected to a vacuum degassing process, the pressure of the vacuum chamber is controlled at 50-80Pa, and th...

Embodiment 2

[0024] The high-strength wear-resistant ball mill steel ball proposed by the present invention includes the following components in weight percentage: C 1.0%, Si 0.2%, Mn 1.2%, Cr 1.3%, W 0.23%, Ti 0.10%, P 0.01% , S≤0.02%, the balance is Fe and a small amount of impurities.

[0025] Its preparation method comprises the following steps:

[0026] S1: Melting, heating the temperature of the melting furnace to 1600°C, and adding W, Fe, Cr and Ti with corresponding specific gravity into the melting furnace for melting, after all melting, the molten steel is obtained;

[0027] S2: Refining, transfer the above molten steel to a refining furnace at a temperature of 1500°C, add C, Si, Mn, P and S with corresponding specific gravity, and add hexachloroethane at the same time for preliminary refining, and then the preliminary refining The molten steel is subjected to a vacuum degassing process, the pressure of the vacuum chamber is controlled at 50-80 Pa, and the degassing is carried o...

Embodiment 3

[0030] The high-strength wear-resistant ball mill steel ball proposed by the present invention includes the following components in weight percentage: C0.9%, Si 0.3%, Mn 0.8%, Cr 1.0%, W 0.23%, Ti 0.04%, P 0.02% , S 0.03%, the balance is Fe and a small amount of impurities.

[0031] Its preparation method comprises the following steps:

[0032] S1: Melting, heating the temperature of the melting furnace to 1800°C, and adding W, Fe, Cr and Ti of corresponding specific gravity into the melting furnace for melting, after all melting, the molten steel is obtained;

[0033] S2: Refining, transfer the above molten steel to the refining furnace at a temperature of 1450°C, add C, Si, Mn, P and S with the corresponding specific gravity, and add hexachloroethane at the same time for preliminary refining, and then the preliminary refining The molten steel is subjected to a vacuum degassing process, the pressure of the vacuum chamber is controlled at 50-80Pa, and the degassing is carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com