Flux-cored wire for stainless steel

A stainless steel, gas-electric welding technology, applied in the direction of arc welding equipment, welding/welding/cutting items, welding media, etc., can solve the problems of reduced toughness, unsuitable for welding, reduced toughness of welded parts, etc., and reach the yield point and tensile strength Effect of improving and suppressing the decrease of toughness and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

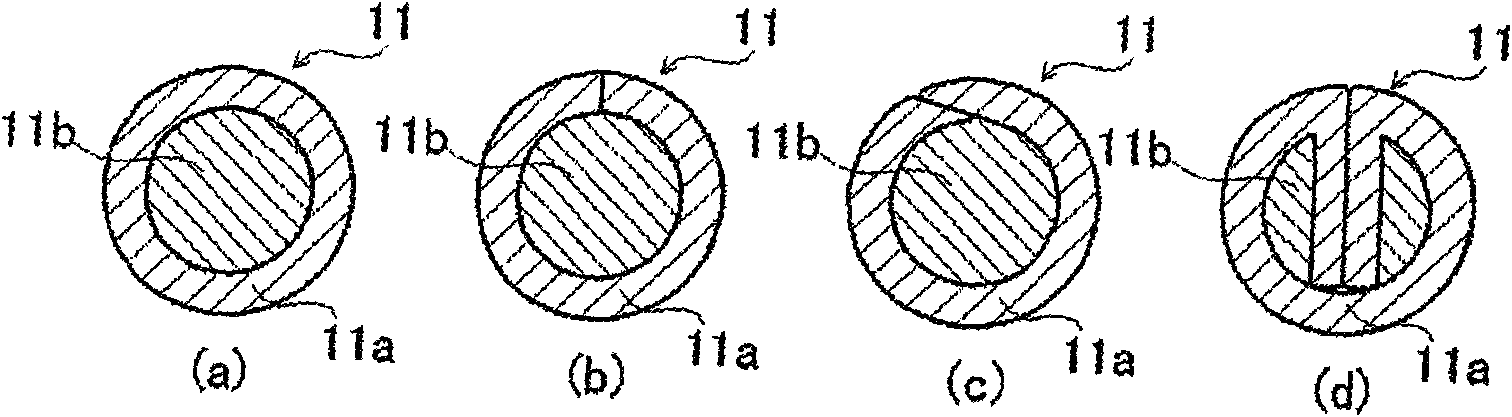

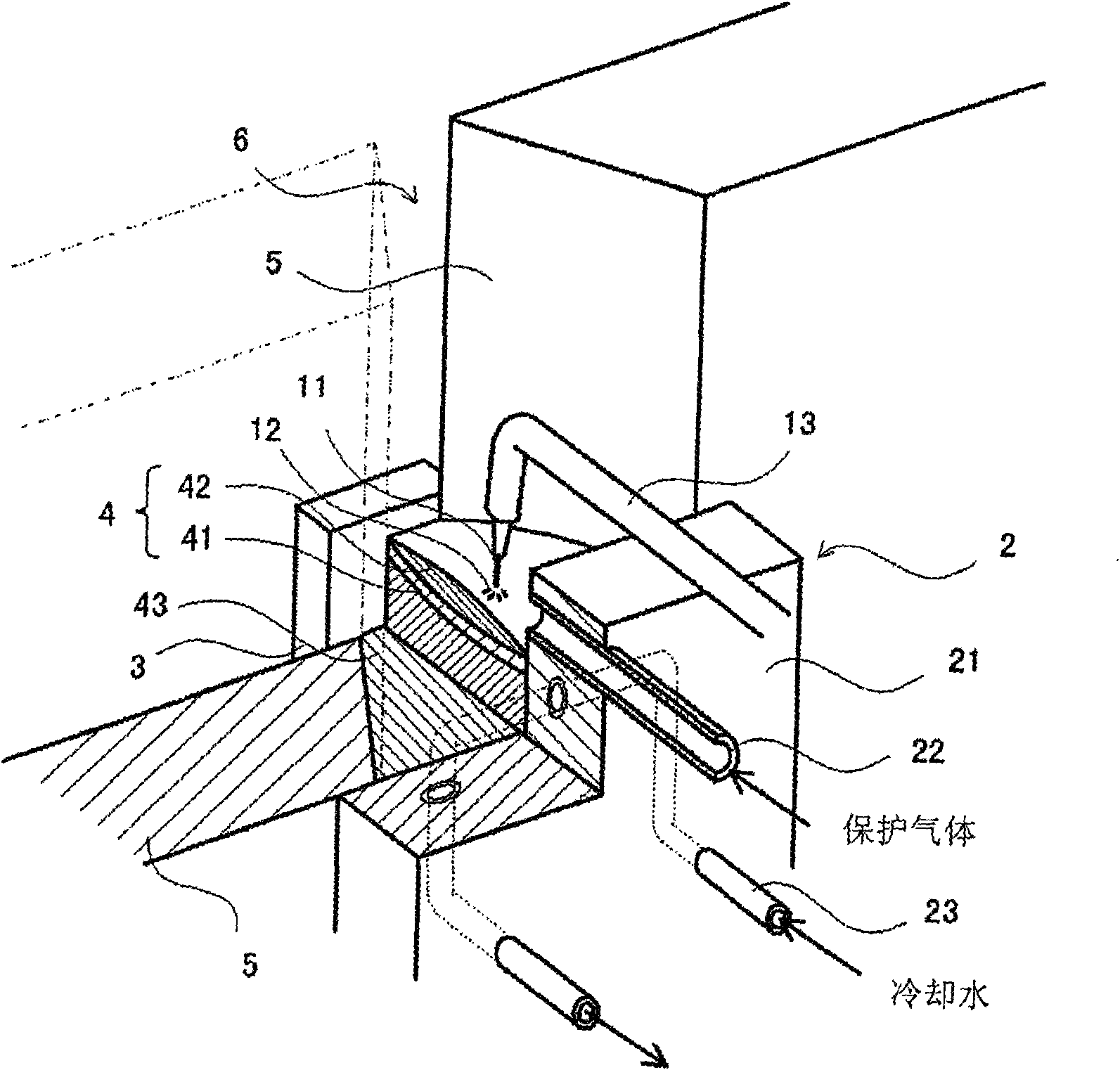

[0021] figure 1 It is a cross-sectional view showing a welding wire for gas electric welding, figure 2 It is a perspective view showing a welding part of gas electric welding in a part of vertical and horizontal sections.

[0022] Such as figure 2 As shown, the gas-electric welding is carried out in the following manner. A liner 3 is placed on the groove 6 between the base metals 5 in a vertical position, and a sliding copper plate 2 is installed on the operator's side, and the welding wire 11 is supplied to the groove 6 by the welding torch 13. , and arc discharge occurs between the weld metal 43 and the welding wire 11 at the same time. The shielding gas is supplied to the welding part from the gas supply port 22 provided in the sliding copper plate 2, and by covering the arc 12 and the welding part 4 with the shielding gas, it is possible to prevent the intrusion of air into the welding atmosphere. The sliding copper plate 2 slides up and down along with the movement o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com