Method for preparing foamed aluminum composite material

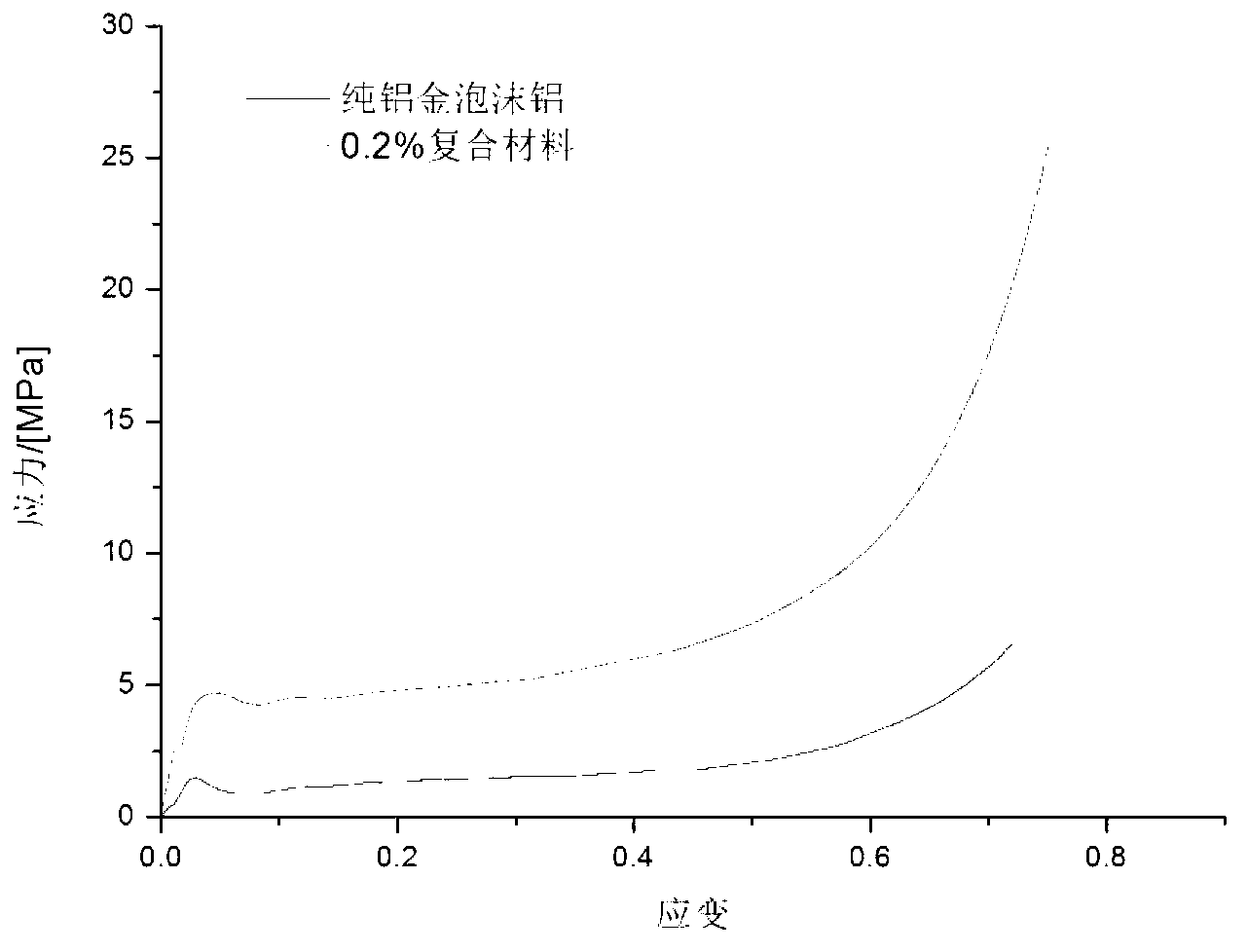

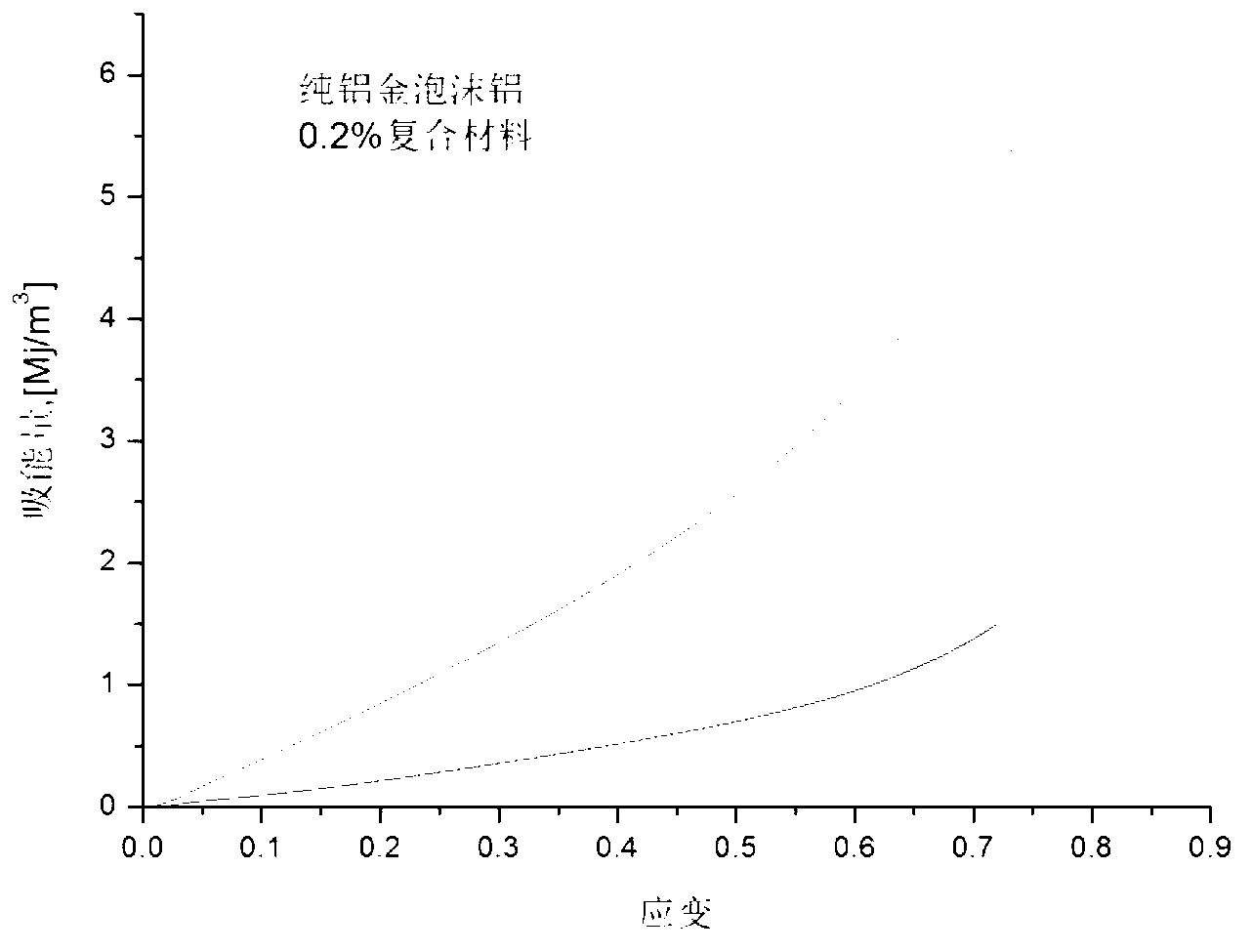

A composite material and foamed aluminum technology, which is applied in the field of preparation of foamed aluminum composite materials, can solve problems such as low compressive strength and brittle fracture, and achieve the effects of high compressive strength, high ductile fracture, and good ductile fracture behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is to cut commercial pure aluminum ingots with a purity of 99.5% by mass of industrial pure aluminum into aluminum blocks, take 855g of aluminum blocks and put them into the crucible, start the resistance furnace to raise the temperature to 800°C, keep it warm for 15 minutes, and make the crucible The aluminum block melts and maintains a uniform temperature;

[0028] In the second step, adjust the temperature of the resistance furnace in the first step to 700°C and keep it warm for 15 minutes so that the overall temperature of the aluminum liquid in the crucible is 700°C. 2% calcium metal particles by mass, start the stirring paddle at the same time, keep the stirring speed at 500r / min, and the stirring time is 8 minutes, so that the calcium metal particles added are evenly dispersed;

[0029] The third step is to add commercial manganese particles with a particle size of 100 meshes that are pre-packed with aluminum foil to the aluminum melt obtained in t...

Embodiment 2

[0036] The first step is to cut industrial pure aluminum and commercial pure aluminum ingots with a purity of 99.5% by mass into aluminum blocks, take 800g of aluminum blocks and put them into the crucible, start the resistance furnace to raise the temperature to 800°C, and keep it warm for 10 minutes to make the The aluminum block melts and maintains a uniform temperature;

[0037] In the second step, adjust the temperature of the resistance furnace in the first step to 700°C and keep it warm for 20 minutes, so that the overall temperature of the aluminum liquid in the crucible is 700°C, and add 1.5% of the mass of the aluminum liquid wrapped in aluminum foil to the aluminum liquid Aluminum powder, start the stirring paddle at the same time, keep the stirring speed at 600r / min, and the stirring time is 2 minutes, so that the added aluminum powder is dispersed evenly;

[0038] The third step is to add commercial manganese particles with a particle size of 80 meshes that are pre-...

Embodiment 3

[0042] The first step is to cut commercial pure aluminum ingots with a purity of 99.5% by mass into aluminum blocks, take 1000g of aluminum blocks and put them into the crucible, start the resistance furnace to raise the temperature to 800°C, keep it warm for 20 minutes, and make the crucible The aluminum block melts and maintains a uniform temperature;

[0043] In the second step, adjust the temperature of the resistance furnace in the first step to 700°C, keep it warm for 30 minutes, so that the overall temperature of the aluminum liquid in the crucible is 700°C, and add 5% of the mass of the aluminum liquid wrapped in aluminum foil to the aluminum liquid Silicon carbide particles, start the stirring paddle at the same time, keep the stirring speed at 1000r / min, and stir for 20 minutes, so that the added silicon carbide particles are evenly dispersed;

[0044] The third step is to add commercial manganese particles with a particle size of 500 meshes that are pre-packed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com