Slab head and tail width prediction-based variable step size control method for rough rolling sizing machine

A control method and width-fixing machine technology, applied in the direction of rolling mill control devices, metal rolling, length measuring devices, etc., can solve problems such as the complexity of head and tail shapes, achieve optimal head and tail shape control, improve yield and width control The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

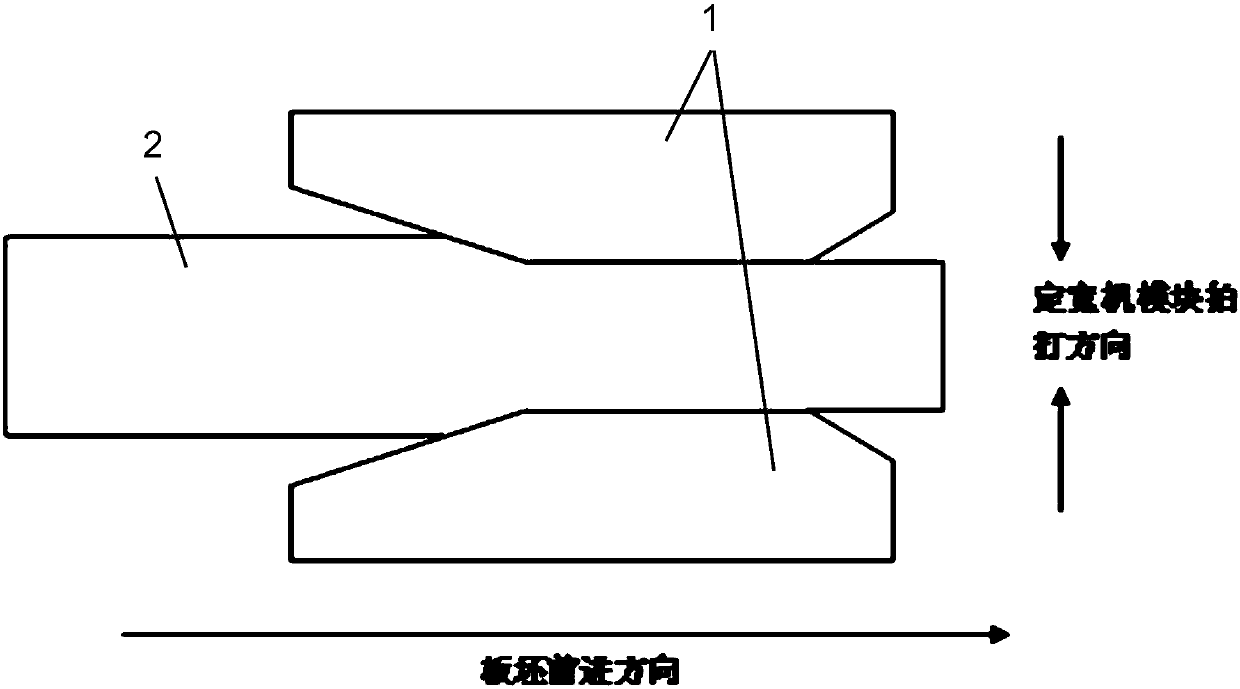

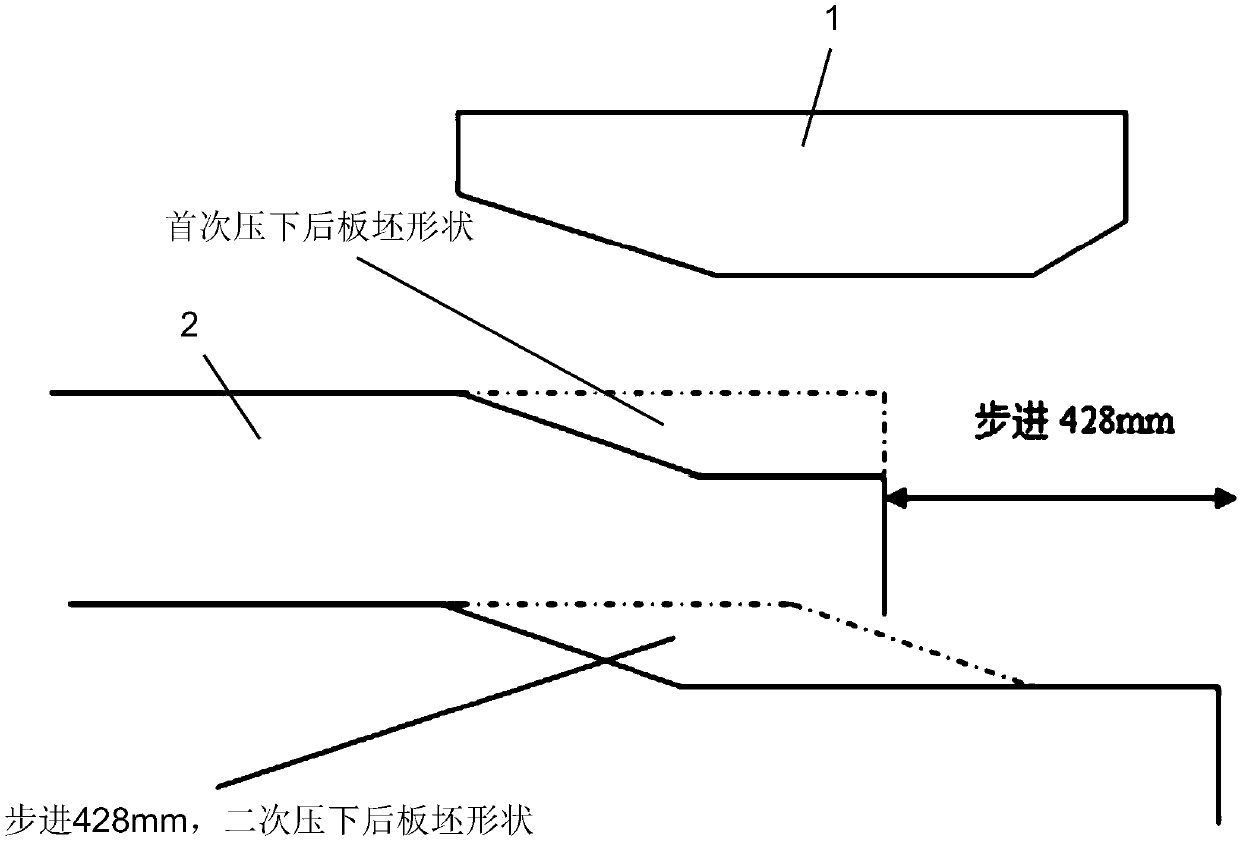

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

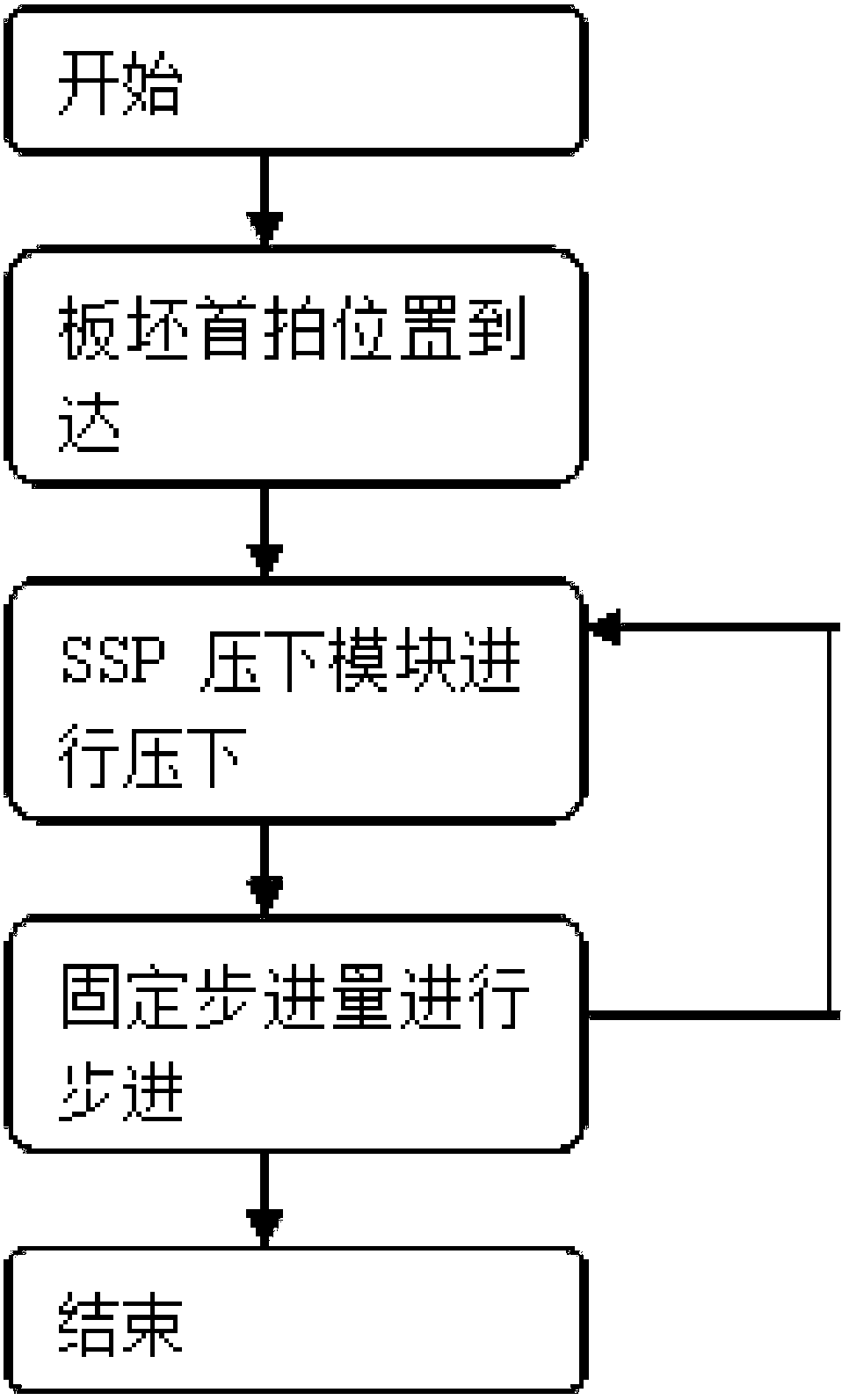

[0025] Please combine Figure 4 to Figure 5 As shown, the variable step length control method based on the prediction of the head and tail width of a rough rolling mill provided by the present invention comprises the following steps:

[0026] S1. Calculate the head width deviation;

[0027] The factors affecting the prediction of the head and tail width of the slab include a series of factors such as the slab width, side pressure, slab temperature, width-to-thickness ratio, etc., which can be calculated using classical formulas, or the main influencing factors can be determined according to the characteristics of the production line, based on process data Determining the parameters and the specific method for predicting the width of the head and tail are not regarded as the content of the invention.

[0028] The embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com