Recycling and re-preparation method of silicon-steel level magnesium oxide

A magnesia and silicon steel grade technology, applied in the direction of magnesia, etc., can solve the problems of low purity, low content of silicon steel grade magnesia magnesia, uneven particle size, etc., and achieve the effect of simple process flow, increased bulkiness, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

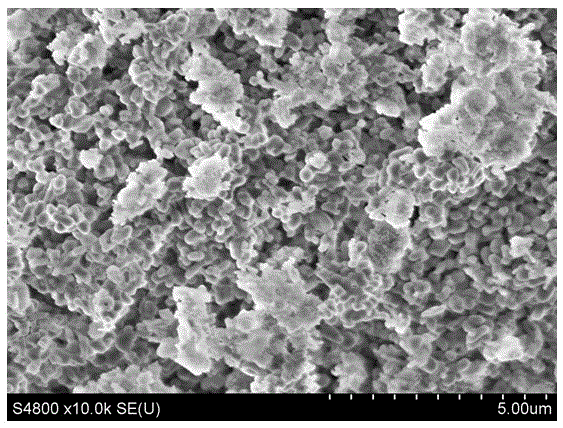

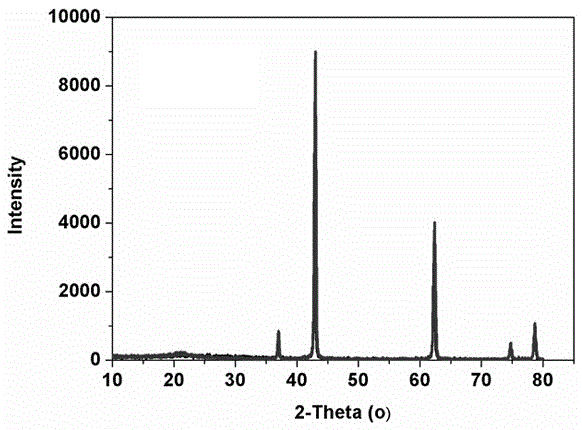

Image

Examples

Embodiment 1

[0019] a. The magnesia waste used for silicon steel was calcined at a high temperature in a 600°C tube furnace fed with oxygen to remove excess carbon to obtain a gray-white waste sample.

[0020] b. Add the off-white waste obtained in a. to regenerated hydrochloric acid with a mass fraction of 16%, the ratio of waste to regenerated acid is 1g:9ml, dissolve and react in a water bath at 60°C for 4 hours, and filter to obtain yellow Green crude Mg 2+ solution.

[0021] c. The crude Mg obtained by b 2+ Crude Mg 2+ Solution: The volume ratio of hydrogen peroxide is 5:1. After adding hydrogen peroxide, the solution changes from yellow-green to yellow crude Mg 2+ solution, let it stand for 1h.

[0022] d. Yellow crude Mg obtained from c 2+ In the solution solution, add ammonia water dropwise to control the pH value to 8.5, so that the iron ions can completely generate Fe(OH) 3 Precipitation, but magnesium ions do not precipitate, and the filtrate obtained by filtration is hig...

Embodiment 2

[0026] a. The magnesia waste used for silicon steel was calcined at a high temperature in a 600°C tube furnace fed with oxygen to remove excess carbon to obtain a gray-white waste sample.

[0027] b. Add the off-white waste obtained in a. to regenerated hydrochloric acid with a mass fraction of 16%, the ratio of waste to regenerated acid is 1g:9ml, dissolve and react in a water bath at 60°C for 4 hours, and filter to obtain yellow Green crude Mg 2+ solution.

[0028] c. The crude Mg obtained by b 2+ Crude Mg 2+ Solution: The volume ratio of hydrogen peroxide is 5-1. After adding hydrogen peroxide, the solution changes from yellow-green to yellow crude Mg 2+ solution, let it stand for 1h.

[0029] d. Yellow crude Mg obtained from c 2+ In the solution solution, ammonia water is added dropwise, and the pH value is controlled to be 8.5, so that iron ions completely generate Fe(OH)3 precipitation, while magnesium ions do not precipitate, and the filtrate obtained by filtratio...

Embodiment 3

[0033]a. The magnesia waste used for silicon steel was calcined at a high temperature in a 600°C tube furnace fed with oxygen to remove excess carbon to obtain a gray-white waste sample.

[0034] b. Add the off-white waste obtained in a. to regenerated hydrochloric acid with a mass fraction of 16%, the ratio of waste to regenerated acid is 1g:9ml, dissolve and react in a water bath at 60°C for 4 hours, and filter to obtain yellow Green crude Mg 2+ solution.

[0035] c. The crude Mg obtained by b 2+ Crude Mg 2+ Solution: The volume ratio of hydrogen peroxide is 5-1. After adding hydrogen peroxide, the solution changes from yellow-green to yellow crude Mg 2+ solution, let it stand for 1h.

[0036] d. Yellow crude Mg obtained from c 2+ In the solution solution, add ammonia water dropwise to control the pH value to 8.5, so that iron ions can completely form Fe(OH)3 precipitation, while magnesium ions do not precipitate, and the filtrate obtained by filtration is high-purity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com