Preparation method of carbon-coated iron oxide nanotube and product and application of nanotube

A technology of iron oxide nanometer and carbon coating, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, nano-carbon, etc. It can solve the problems of unfavorable wide application, complex method, and many processes, and achieve short reaction time and high reaction temperature. The effect of low cost and less technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare ferric chloride, sodium sulfate, ammonium dihydrogen phosphate and sucrose into a solution at a certain concentration, wherein the concentration of iron salt is 0.08mol / L, and the concentration of sulfate is 8.0×10 -4 mol / L, the concentration of ammonium dihydrogen phosphate is 6.0×10 -4 mol / L, the added mass of sucrose is 1% of the iron salt, the magnetic stirring rate is 1000 rpm, and the stirring time is 0.5 hour;

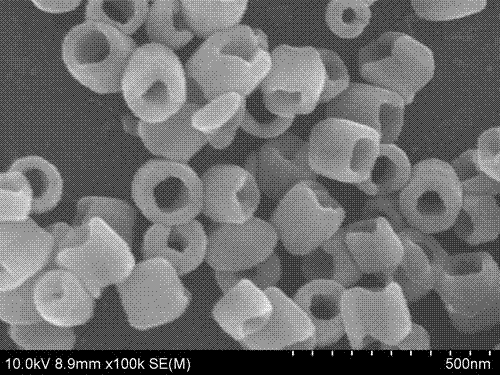

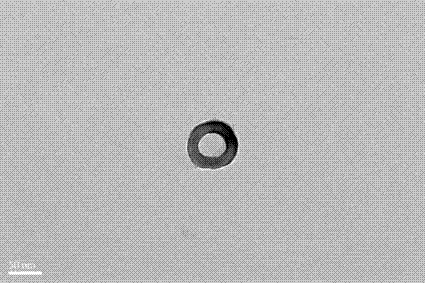

[0024] The solution prepared above was transferred to a stainless steel reaction kettle, and carbon-coated iron oxide nanotubes were prepared by supercritical reaction for a certain period of time. The specific reaction temperature was 120 °C, the pressure was 40 MPa, and the time was 6 hours. After washing and drying, carbon-coated iron oxide nanotubes were obtained. coated iron oxide nanotubes. figure 1 SEM images of carbon-coated iron oxide nanotubes and

[0025] figure 2 TEM image of carbon-coated iron oxide nanotubes. Better control ov...

Embodiment 2

[0028] Prepare ferric nitrate, potassium sulfate, ammonium dihydrogen phosphate and sucrose into a solution at a certain concentration, in which the concentration of iron salt is 0.1mol / L, and the concentration of sulfate is 1.0×10 -3 mol / L, the concentration of ammonium dihydrogen phosphate is 1.0×10 -3 mol / L, the added quality of sucrose is 5% of the iron salt, the magnetic stirring speed is 800 rpm, and the stirring time is 5 hours;

[0029] The solution prepared above was transferred to a stainless steel reaction kettle, and carbon-coated iron oxide nanotubes were prepared by supercritical reaction for a certain period of time. The specific reaction temperature was 130°C, the pressure was 5 MPa, and the time was 5 hours. After washing and drying, carbon-coated iron oxide nanotubes were obtained. coated iron oxide nanotubes.

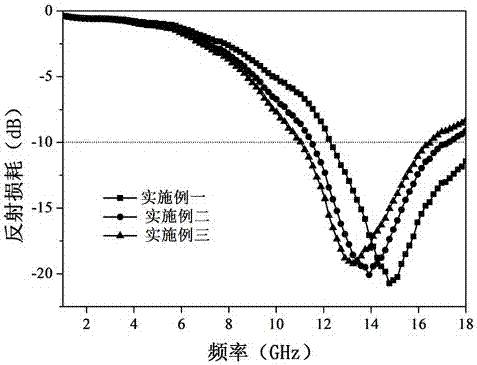

[0030] The prepared carbon-coated iron oxide nanotubes were uniformly mixed with solid paraffin at a mass fraction of 10:90, and pressed on a spec...

Embodiment 3

[0032] Prepare ferric chloride, potassium sulfate, ammonium dihydrogen phosphate and sucrose into a solution at a certain concentration, wherein the concentration of iron salt is 0.09mol / L, and the concentration of sulfate is 6.0×10 -4 mol / L, the concentration of ammonium dihydrogen phosphate is 8.0×10 -4 mol / L, the added quality of sucrose is 3% of the iron salt, the magnetic stirring speed is 100 rpm, and the stirring time is 4 hours;

[0033] The solution prepared above was transferred to a stainless steel reactor, and carbon-coated iron oxide nanotubes were prepared by supercritical reaction for a certain period of time. The specific reaction temperature was 150°C, the pressure was 30 MPa, and the time was 0.5 hours. After washing and drying, carbon-coated iron oxide nanotubes were obtained. coated iron oxide nanotubes.

[0034] The prepared carbon-coated iron oxide nanotubes were uniformly mixed with solid paraffin at a mass fraction of 10:90, and pressed on a special ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com