Process for the preparation of halide perovskite and perovskite-related materials

A halide perovskite, perovskite technology, applied in chemical instruments and methods, lead halide, polycrystalline material growth, etc., can solve the problems of high complexity and high energy input, less popular, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0217] Embodiment 1 metal lead (Pb) is converted into MAPbX 3

[0218] Thermal evaporation of Pb was performed on three different substrates.

[0219] ·Glass microscope slides

[0220] Dense TiO on fluorine-doped tin oxide (FTO)-coated glass 2 (d-TiO 2 ).

[0221] ·(100)p-type (boron-doped) Si

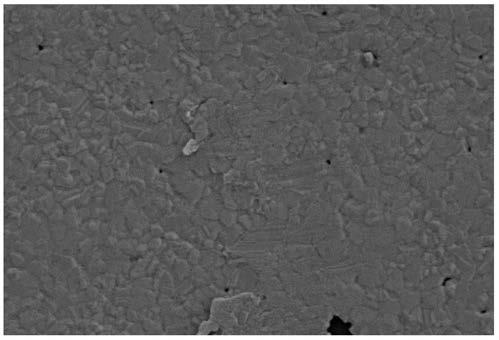

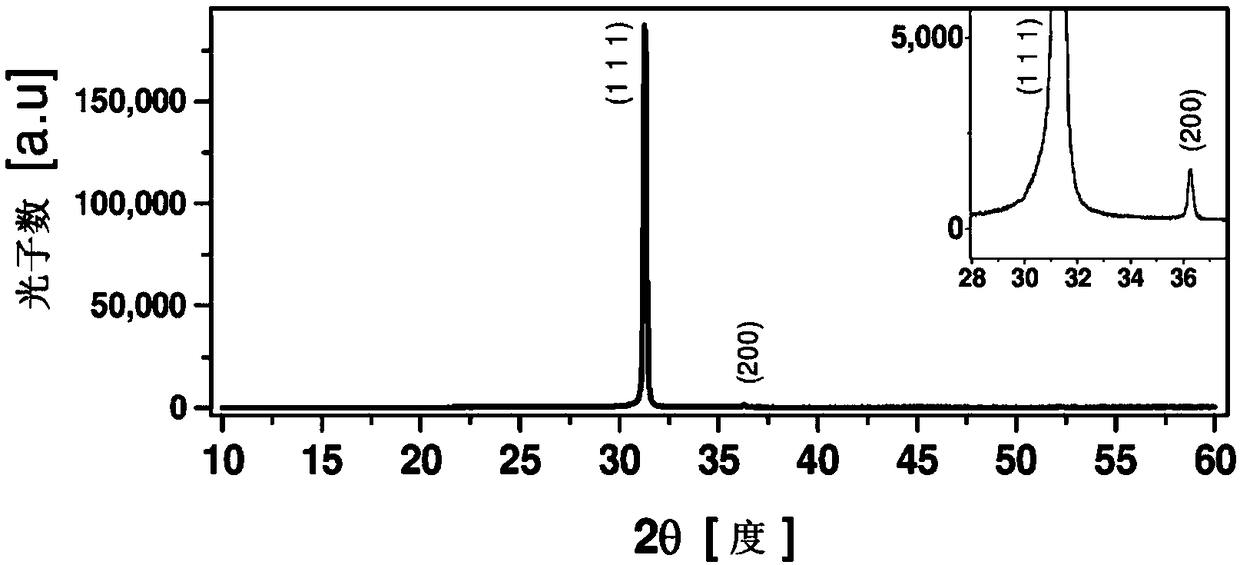

[0222] In all three cases, shiny Pb metal layers with controlled thickness were obtained. Powder X-ray diffraction (XRD) and scanning electron microscope (SEM) images (

[0223] Figures 1A-1D ) and concentration optimization with about 50 or about 120 nm thick evaporated Pb to roughly optimize the morphology.

[0224] The evaporated Pb layer was placed in vials containing 0.05-0.1 M methylammonium iodide (MAI), methylammonium bromide (MABr) and formamidine iodide (FAI) in various alcoholic solutions. The methanol solution of MAI reacts very quickly and essentially etches the layer from the substrate. Ethanol MAI transforms the shiny silver-gray Pb layer into a black coating. ...

Embodiment 2

[0236] Embodiment 2 MAX (X=Br, I) concentration is to MAPbX 3 Effect of film morphology

[0237] The effect of MAX(X=Br,I) concentration on the film morphology is shown below.

[0238] Figures 4A-4E Five different concentrations of MAX are shown: 500 mM, 200 mM, 100 mM, 50 mM and 20 mM. Two effects of increasing the salt concentration are directly seen to be a decrease in crystal size and an increase in the inhomogeneity of the film. Another effect is that cracking of the film occurs at higher concentrations. For solar cell use, the optimum between large crystals and good coverage (smaller crystals) occurs at a concentration of 50-70 mM.

[0239]Membrane morphology is very important in determining membrane properties. The desired morphology depends on the intended use of the film or material.

Embodiment 3

[0240] Embodiment 3 temperature and solvent are to MAPbX 3 Effect of film morphology

[0241] Lower temperature treatments provided better overall coverage ( Figure 7C ), while higher temperatures give on average larger and more anisotropic crystals ( Figure 5 ). Treatment with ethanol instead of IPA resulted in larger crystals but with poorer coverage ( Figure 10A ,10B).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com