Method for manually adjusting and computing shape target curve of cold-rolled steel strip

A technology of manual adjustment and target curve, which is applied in the direction of contour control, etc., can solve problems such as broken belt accidents and poor control effect of strip shape at the exit, and achieve simple steps, improve the level of shape control, and be conducive to stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

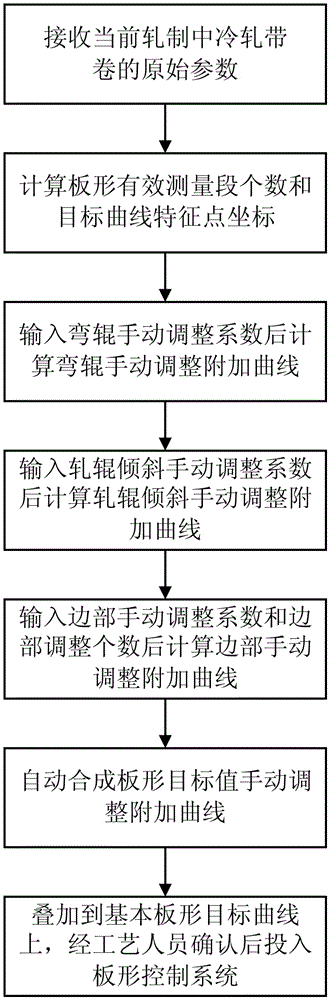

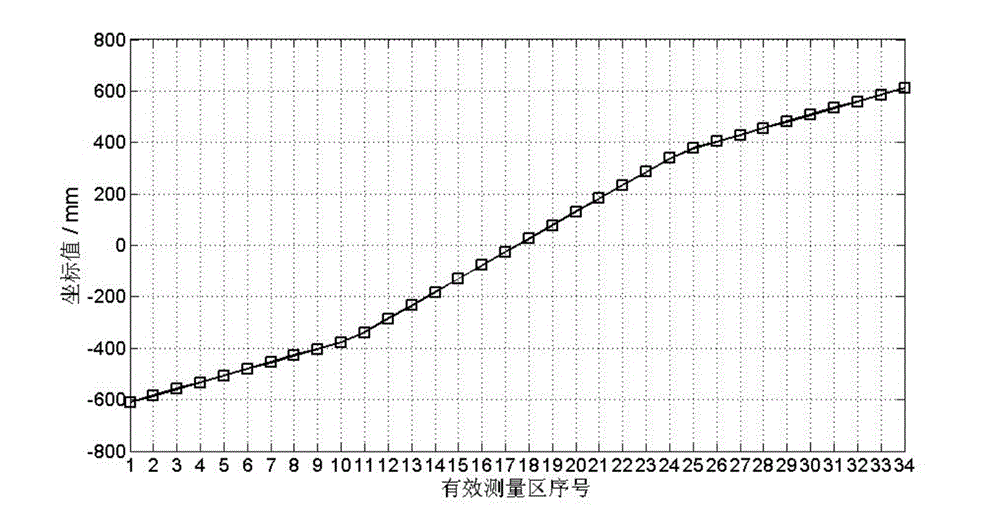

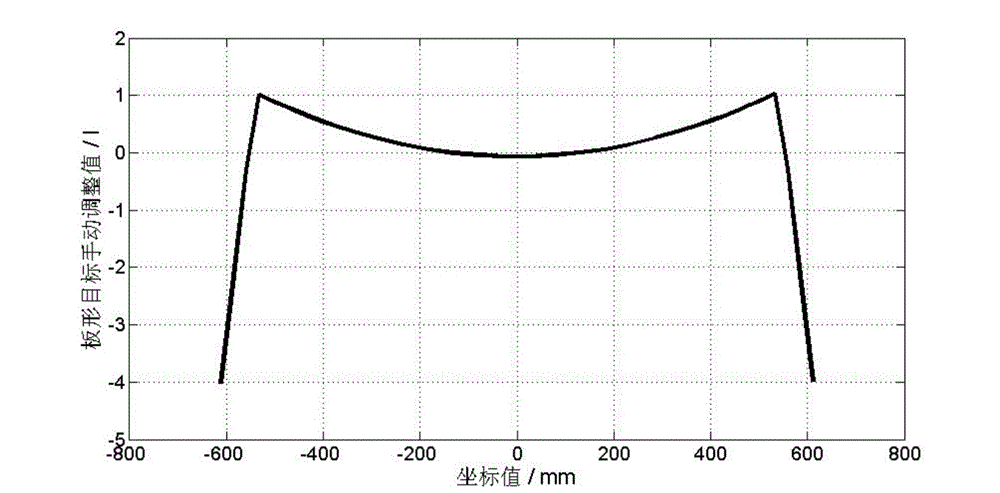

[0038] figure 1 It is a flow chart of the present invention, including the following steps: 1) receiving the original parameters of the cold-rolled strip coil in the current rolling that is transmitted by the process computer in real time, including: the width B of the cold-rolled strip steel, the width measurement section of the middle part of the flat roll number n 1 , the width value of the wide measuring section L 1 , The number of narrow measuring sections at both ends of the plate shape roller 2 , Narrow measurement section width value L 2 ; 2) According to the received original parameters of the cold-rolled coil in the current rolling, calculate the number N of valid measurement sections of the flatness; the criterion for judging whether the measurement section is valid is: when the strip coverage of the measurement section of the flatness roll exceeds 50% of the measurement section is considered to be valid; take the horizontal center point of the strip as the coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com