Online calculating method for wrap angle of cold-rolled strip steel plate shape roll

A calculation method and strip shape technology, applied in the direction of contour control, etc., can solve problems such as the deterioration of the exit strip shape control effect and the distortion of the shape detection results, so as to solve the distortion of the shape detection results, ensure the rationality, and improve the The effect of shape control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

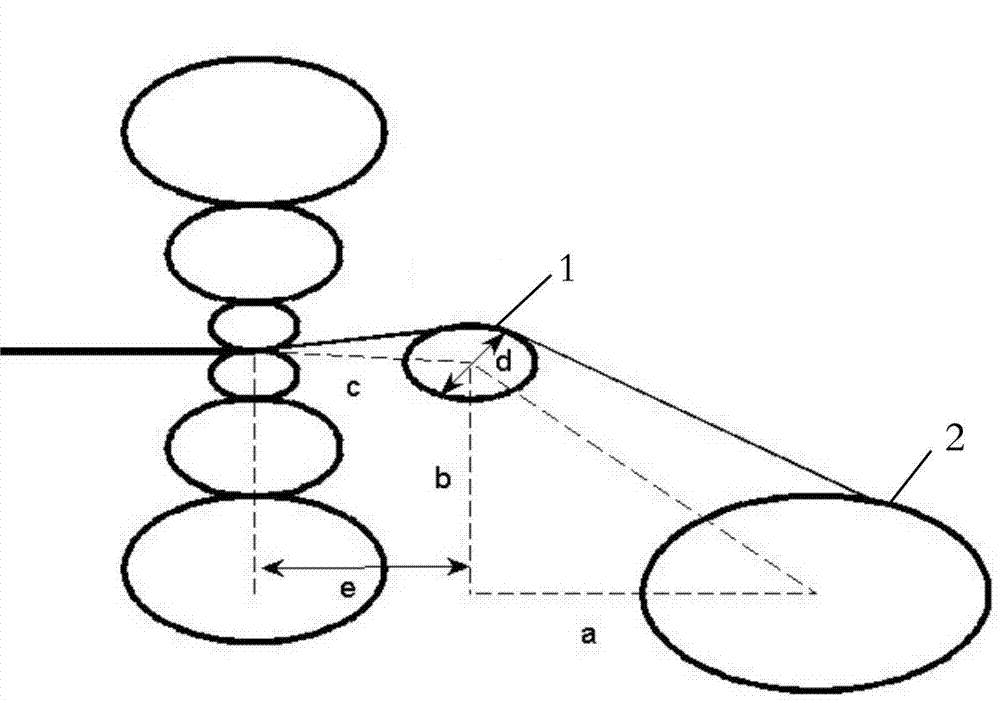

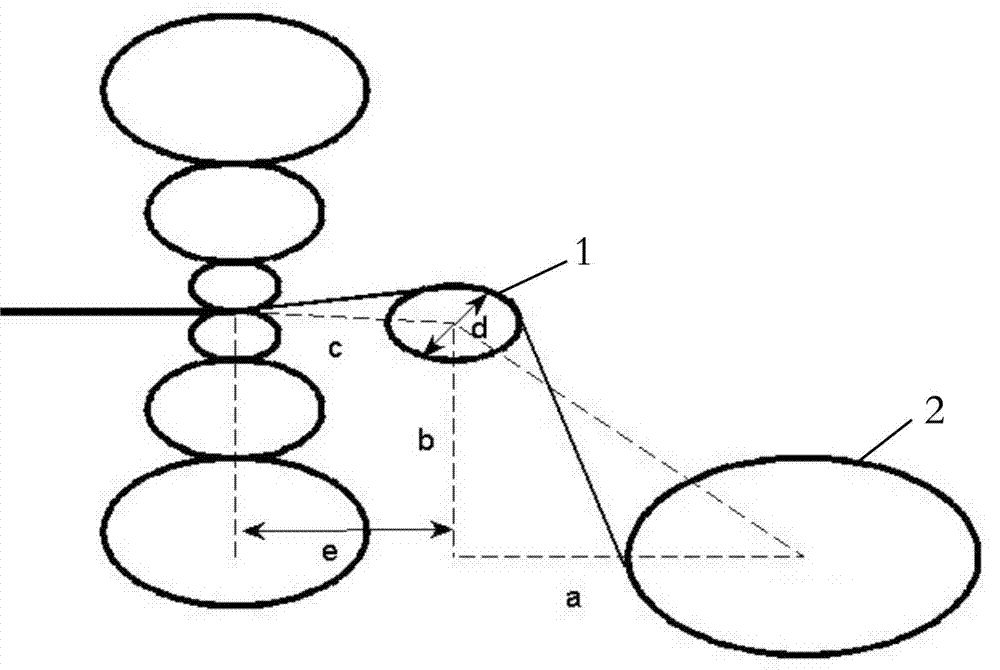

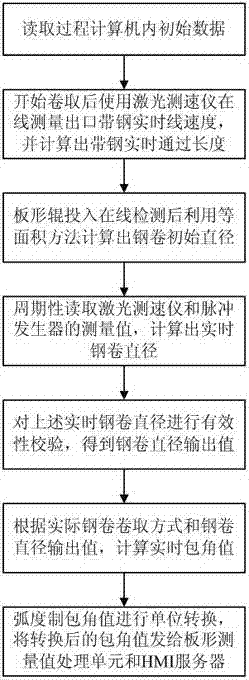

[0041] The present invention provides an online calculation method for the wrap angle of cold-rolled strip shape rolls, such as image 3 As shown, after the strip shape control system reads the initial data in the process computer before the coil threading, the specific workflow of the inventive method put into work is: 1) after the start of coiling, use the laser velocimeter to measure the exit strip in real time. Line speed, and calculate the strip real-time passing length L 1 ; 2) After the shape roll is put into online detection, the equal-area method is used according to the real-time passing length L of the strip steel 1Calculate the initial diameter of the coil; 3) Periodically read the measured values of the laser velocimeter and pulse generator to calculate the real-time coil diameter; 4) Verify the validity of the above-mentioned real-time coil diameter to obtain the coil diameter output 5) Calculate the real-time wrap angle value according to the actual coil coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com