Epoxy microcapsule with polyurea as wall material and preparation method thereof

A microcapsule and wall material technology, which is applied in the field of epoxy microcapsules and its preparation, can solve the problems of unsuitable epoxy microcapsule wall material and loss of repair function, etc., and achieve simple shape control, smooth surface and good sphericity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Embodiments of the present invention also provide a method for preparing epoxy microcapsules using polyurea as a wall material, which includes the following steps:

[0016] S01: Disperse polyisocyanate and liquid epoxy resin in water containing surfactant to obtain a mixed solution, wherein the polyisocyanate and liquid epoxy resin are the oil phase, and the water containing surfactant is the water phase , the polyisocyanate includes ternary or more than ternary polyisocyanate, the mass ratio of the oil phase to the water phase is 1:5-10, and the mass ratio of the polyisocyanate to the liquid epoxy resin in the oil phase is 1 : 1~2.3, the concentration of surfactant in the water phase is 0.5~3%;

[0017] S02: Stir the mixed solution at 25-90° C. for 0.5-5 hours, filter, wash and dry to obtain the epoxy microcapsules with polyurea as the wall material.

[0018] Wherein, in step S01, the polyisocyanate is 4,4′,4″-triphenylmethane triisocyanate (TTI), tris(4-isocyanatophe...

Embodiment 1

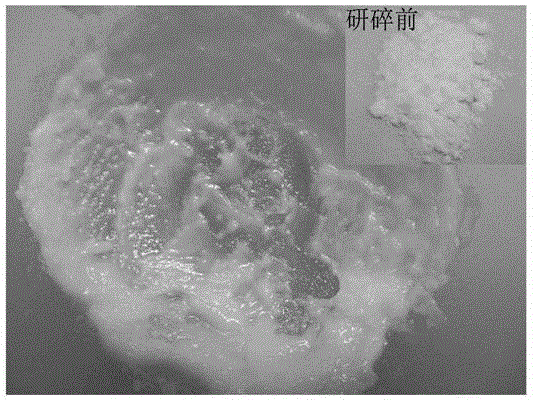

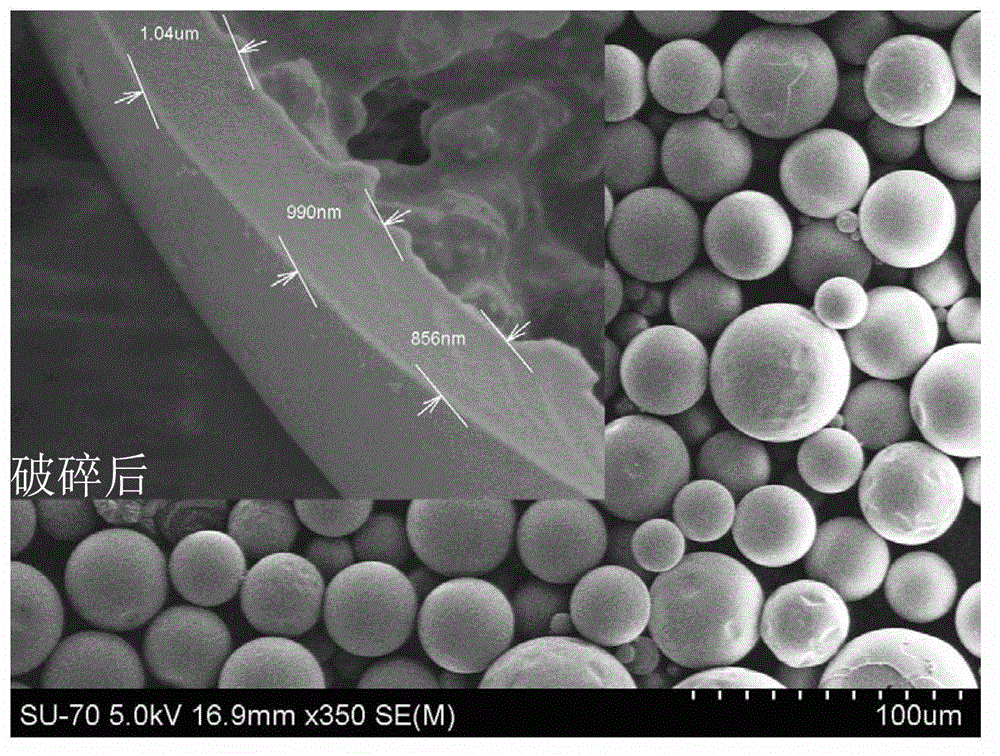

[0029] Mix 8g of TTI (molecular weight 367), 10g of epoxy E-51, and 1.5g of acetone evenly, add to a three-necked flask containing 100g of 1% PVA solution, and emulsify at 60°C and 1000rpm for 30min. Reduce the rotation speed to 400 rpm, add 0.03 g of catalyst dibutyltin dilaurate (DBTDL), and keep the reaction at 60°C for 3 hours. The reaction solution was filtered, washed with distilled water, filtered again, and repeated three times, and then dried at 45° C. for 12 hours to obtain a white powder of polyurethane-coated epoxy microcapsules. SEM observation confirmed that microcapsules with a particle size distribution of 20-70 μm and a wall thickness of 800-1000 nm were obtained, such as figure 1 shown. Fourier transform infrared spectroscopy (FTIR) analysis found that at 1640cm -1 There is a strong urea C=O group absorption peak, which proves that the wall material is polyurea. After the microcapsules are crushed with a mortar, observed with an optical microscope, it can ...

Embodiment 2

[0031]Weigh 8g DTTI (molecular weight 436), add a small amount of ethyl acetate to make a solution, mix it with 10g epoxy E-51 evenly, add it to a three-necked flask with 100g 1% SMA (Scripset520) solution, at 15°C, 1000rpm After emulsifying for 10 minutes, reduce the rotation speed to 400 rpm, add 0.03 g of catalyst DBTDL after mixing evenly, raise the temperature to 60 ° C, and keep it warm for 3 hours. The reaction solution was filtered, washed with distilled water, filtered again, and repeated three times, and then dried at 45° C. for 12 hours to obtain a white powder of polyurethane-coated epoxy microcapsules. SEM observation shows microcapsules with a particle size distribution of 20-80 μm and a wall thickness of 800-900 nm. FTIR spectrum confirmed that the wall material was polyurea. Observation of the pulverized microcapsules with an optical microscope reveals sticky liquid epoxy flowing out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com