Kapok fiber/manganese dioxide structure multi-layer self-drive tubular micro-nano motor and preparing method thereof

A technology of kapok fiber and manganese dioxide, which is applied in fiber treatment, plant fiber, medical preparations of non-active ingredients, etc., can solve problems such as weak biocompatibility and biodegradability, complicated preparation process, and difficult surface modification , to achieve good biodegradability, good biodegradability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a multilayer self-driven tubular micro-nano motor constructed of kapok fiber / manganese dioxide comprises the following steps:

[0023] (1) Potassium permanganate solution preparation: mix and stir an appropriate amount of potassium permanganate and pure water evenly to obtain a potassium permanganate solution with a concentration of 0.5mol / L;

[0024] (2) Kapok fiber treatment: shred the kapok fiber to a length of 150 μm;

[0025] (3) Preparation of tubular micro-nano motors: Take 0.56 g of kapok fibers shredded in step (2) and soak them in 30 mL of potassium permanganate solution obtained in step (1) for 24 hours, then wash and vacuum dry to obtain kapok fibers / two Multilayer self-propelled tubular micro-nanomotor constructed of manganese oxide.

Embodiment 2

[0027] A method for preparing a multilayer self-driven tubular micro-nano motor constructed of kapok fiber / manganese dioxide comprises the following steps:

[0028] (1) Potassium permanganate solution preparation: mix and stir an appropriate amount of potassium permanganate and pure water evenly to obtain a potassium permanganate solution with a concentration of 0.25mol / L;

[0029] (2) Kapok fiber treatment: shred the kapok fiber to a length of 100 μm;

[0030] (3) Preparation of tubular micro-nano motor: Take 0.56g of kapok fibers shredded in step (2) and soak them in 30mL of potassium permanganate solution obtained in step (1) for 48 hours, then wash and vacuum dry to obtain kapok fibers / two Multilayer self-propelled tubular micro-nanomotor constructed of manganese oxide.

Embodiment 3

[0032] A method for preparing a multilayer self-driven tubular micro-nano motor constructed of kapok fiber / manganese dioxide comprises the following steps:

[0033] (1) Potassium permanganate solution preparation: Mix and stir an appropriate amount of potassium permanganate and pure water evenly to obtain a potassium permanganate solution with a concentration of 1mol / L;

[0034] (2) Kapok fiber treatment: shred the kapok fiber to a length of 200 μm;

[0035] (3) Preparation of tubular micro-nano motors: Take 0.56 g of kapok fibers shredded in step (2) and soak them in 30 mL of potassium permanganate solution obtained in step (1) for 72 hours, then wash and vacuum dry to obtain kapok fibers / two Multilayer self-propelled tubular micro-nanomotor constructed of manganese oxide.

[0036] Performance Characterization:

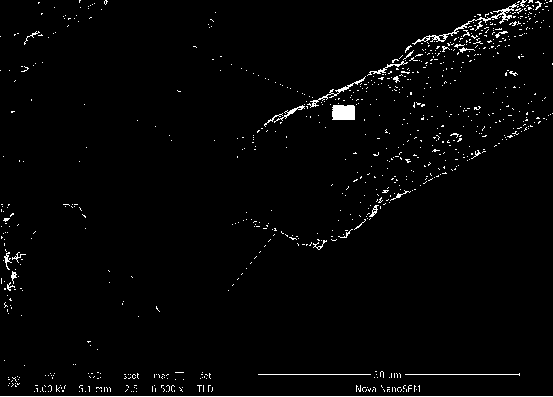

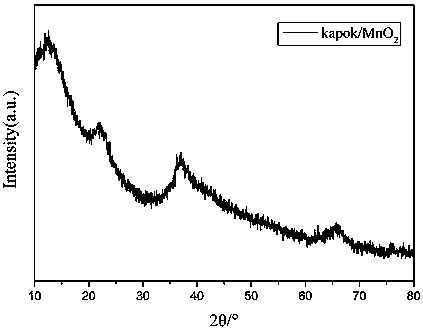

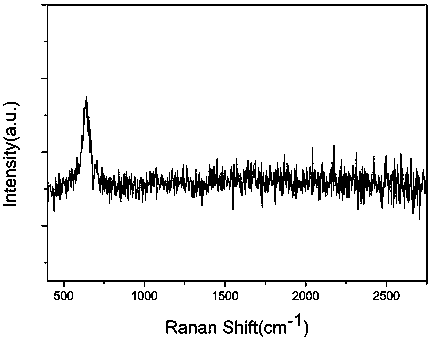

[0037] figure 1 For kapok fiber loading MnO in embodiment 1 2 FESEM image of nanoparticles. It can be seen from the figure that a layer of irregular-shaped MnO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com