High-efficiency large polycrystalline silicon reducing furnace

A technology of polysilicon and reduction furnace, which is applied in the growth of polycrystalline materials, silicon, single crystal growth, etc., can solve the problems of uneconomical, large and unreasonable volume of the furnace drum in the area of the chassis, and achieve the reduction of production power consumption and cost, and effective Conducive to shape control and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

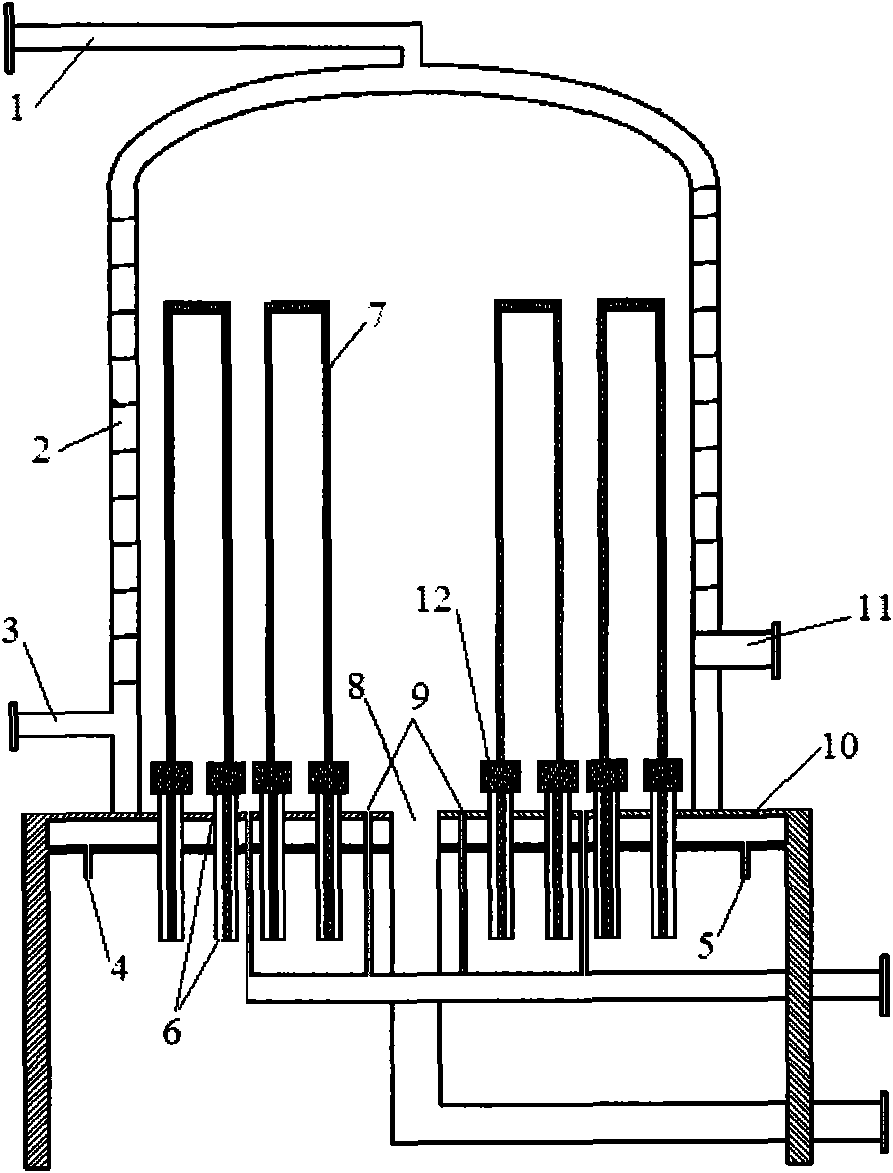

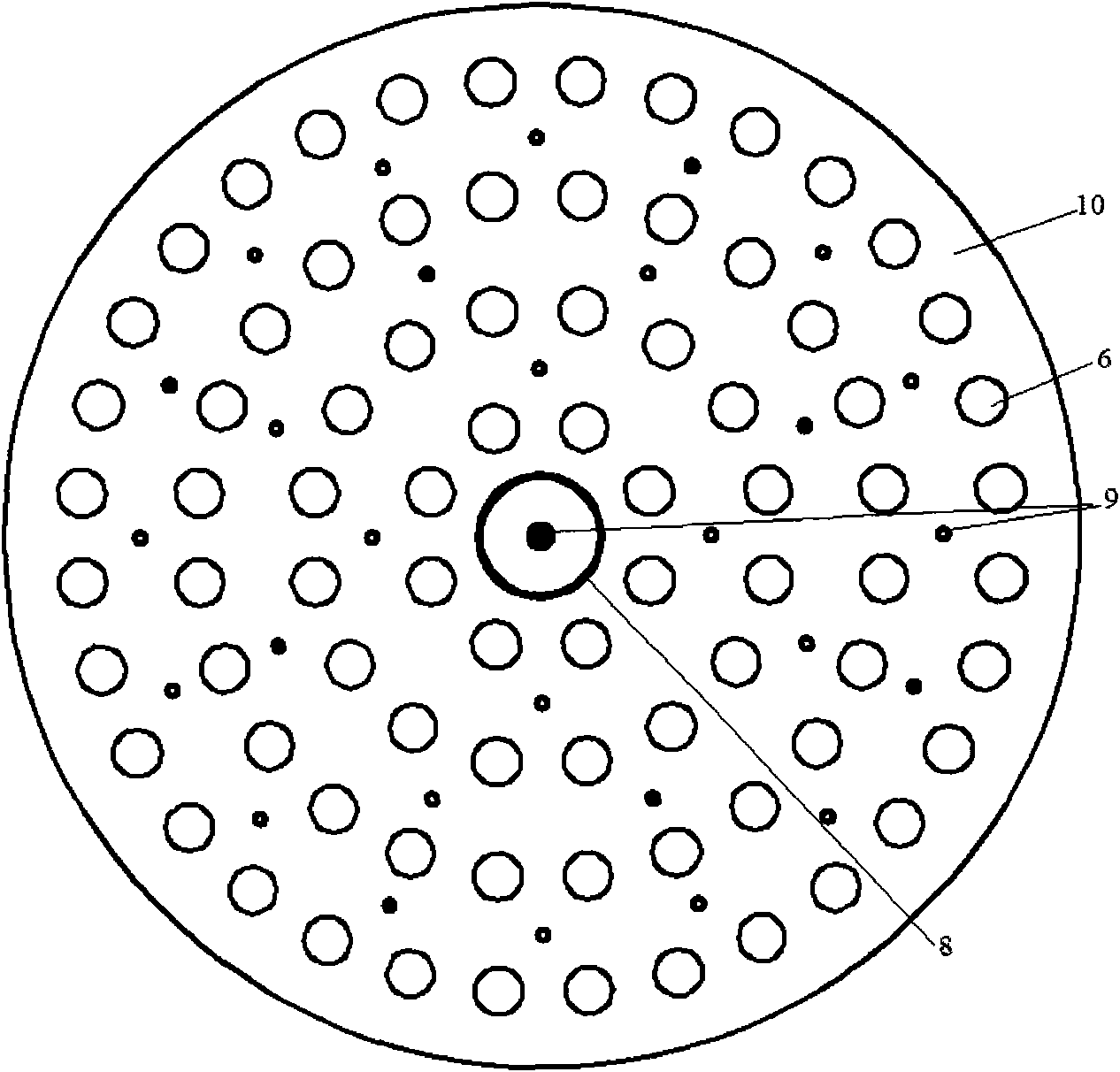

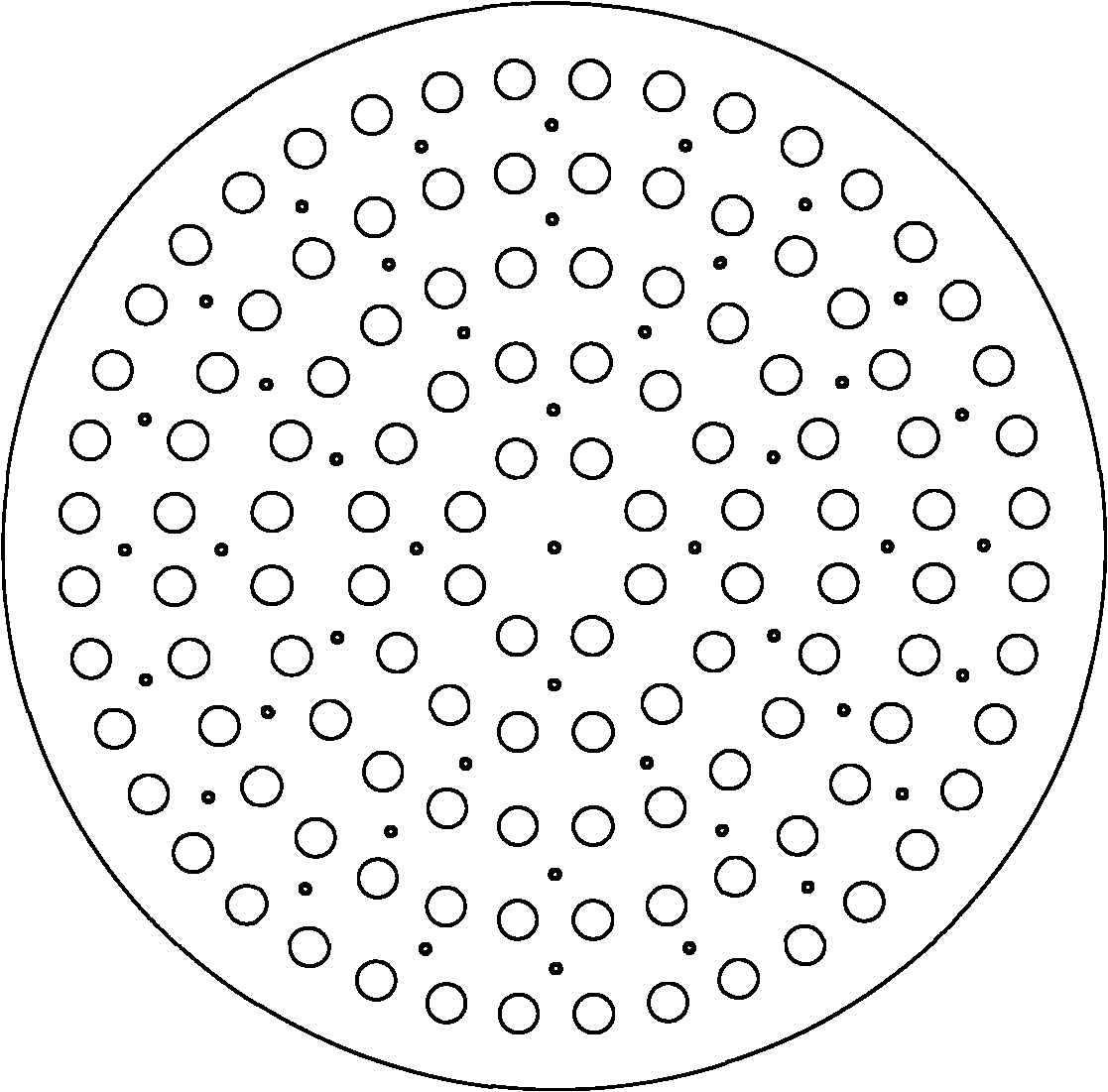

[0031] Such as figure 1 In the conventional polysilicon reduction furnace shown, the chamber surrounded by the chassis 10 and the reduction furnace drum 2 with cooling jacket constitutes the space for chemical vapor deposition reaction, wherein the lower part of the reduction furnace drum 2 with cooling jacket is provided with Furnace cylinder cooling water supply pipe 3, furnace cylinder cooling water return pipe 1 is provided at the top of furnace cylinder 2, chassis cooling water supply pipe 4 and chassis cooling water return pipe 5 are respectively provided at the lower part of chassis 10, and an observation port is provided at the lower part of furnace cylinder 2 11. There are many pairs of electrodes 6, a plurality of air inlets 9 and an air outlet 8 evenly arranged on the surface of the chassis 10. The copper plate of the electrode is connected to the power supply (not shown) through the bus bar, and the silicon core 7 is housed on the electrode and passed through The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com