Air leakage detecting method for reaction cavity and control method for vacuum reactor

A detection method and reaction chamber technology, applied in semiconductor/solid-state device manufacturing, instruments, measurement devices, etc., can solve the problems of processing system capacity impact, reducing capacity, and reducing the processing time of semiconductor processing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

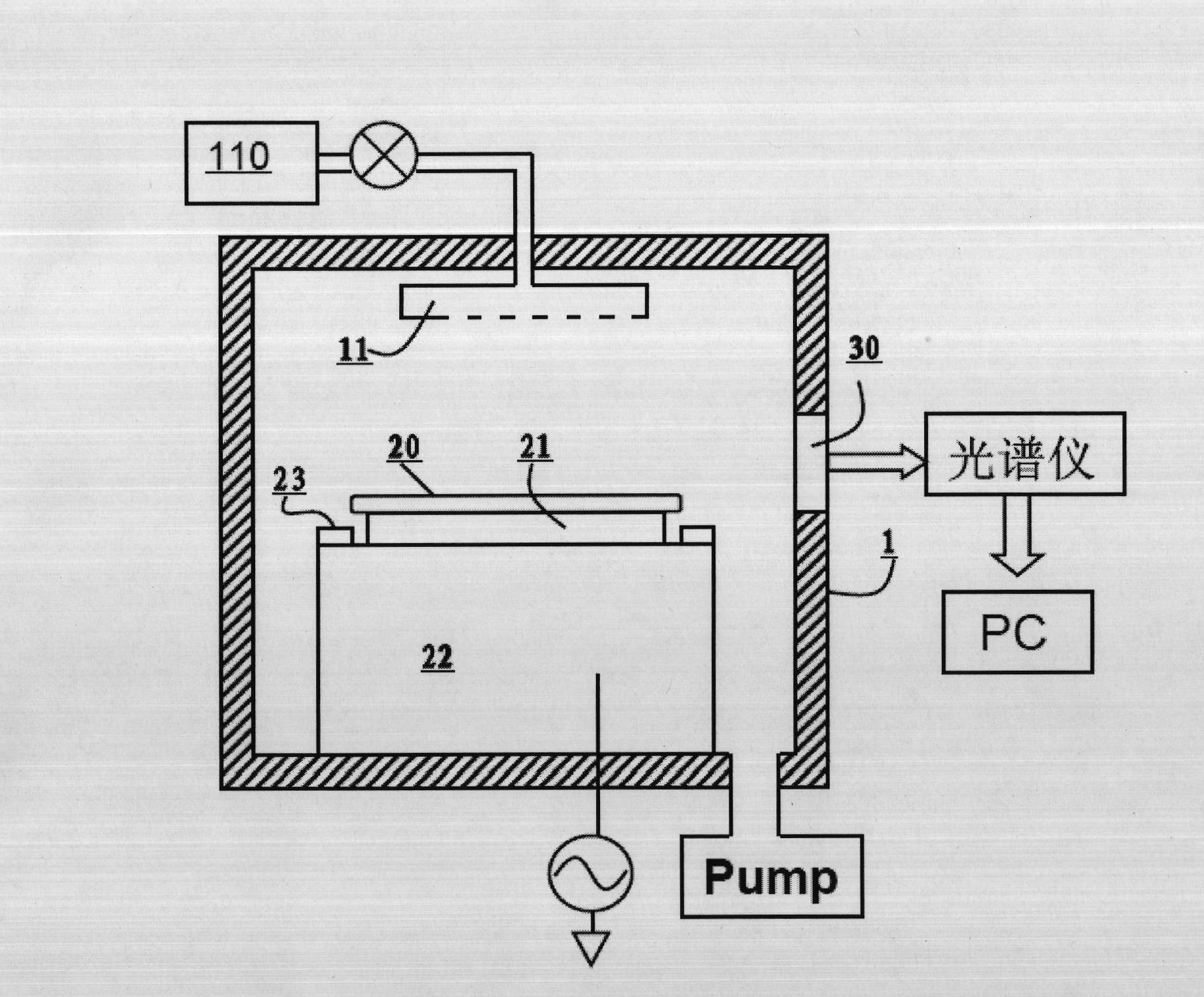

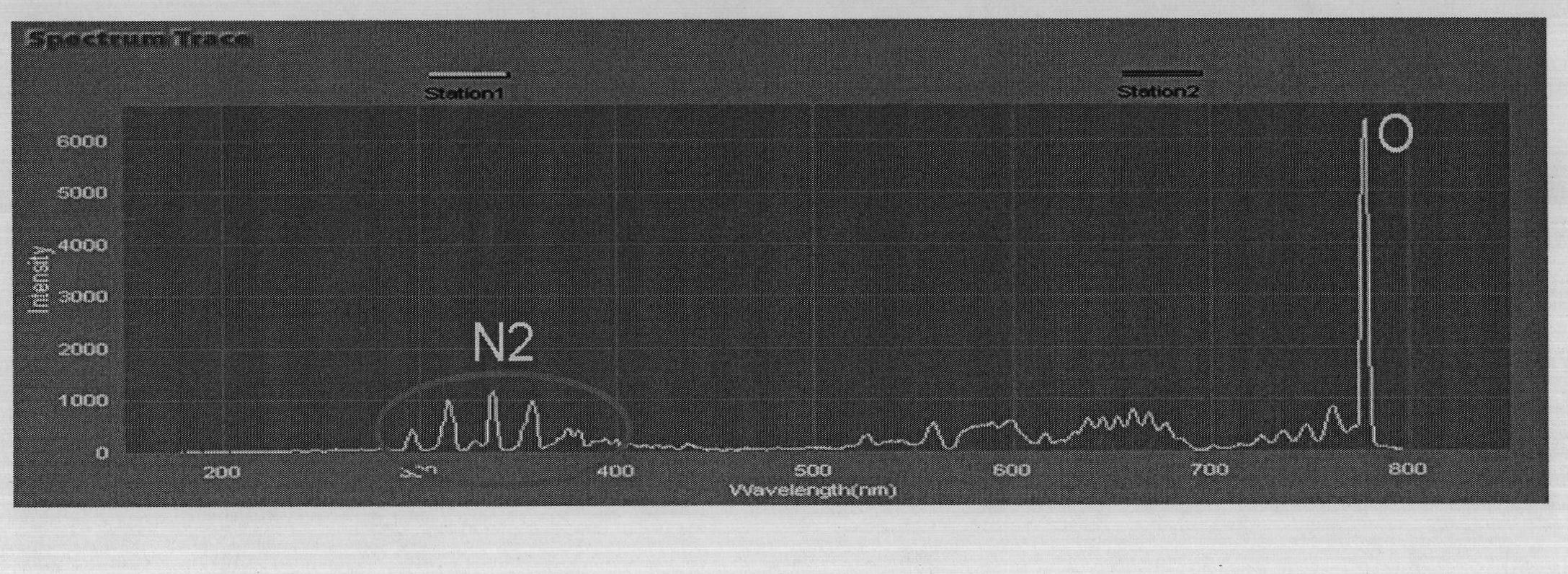

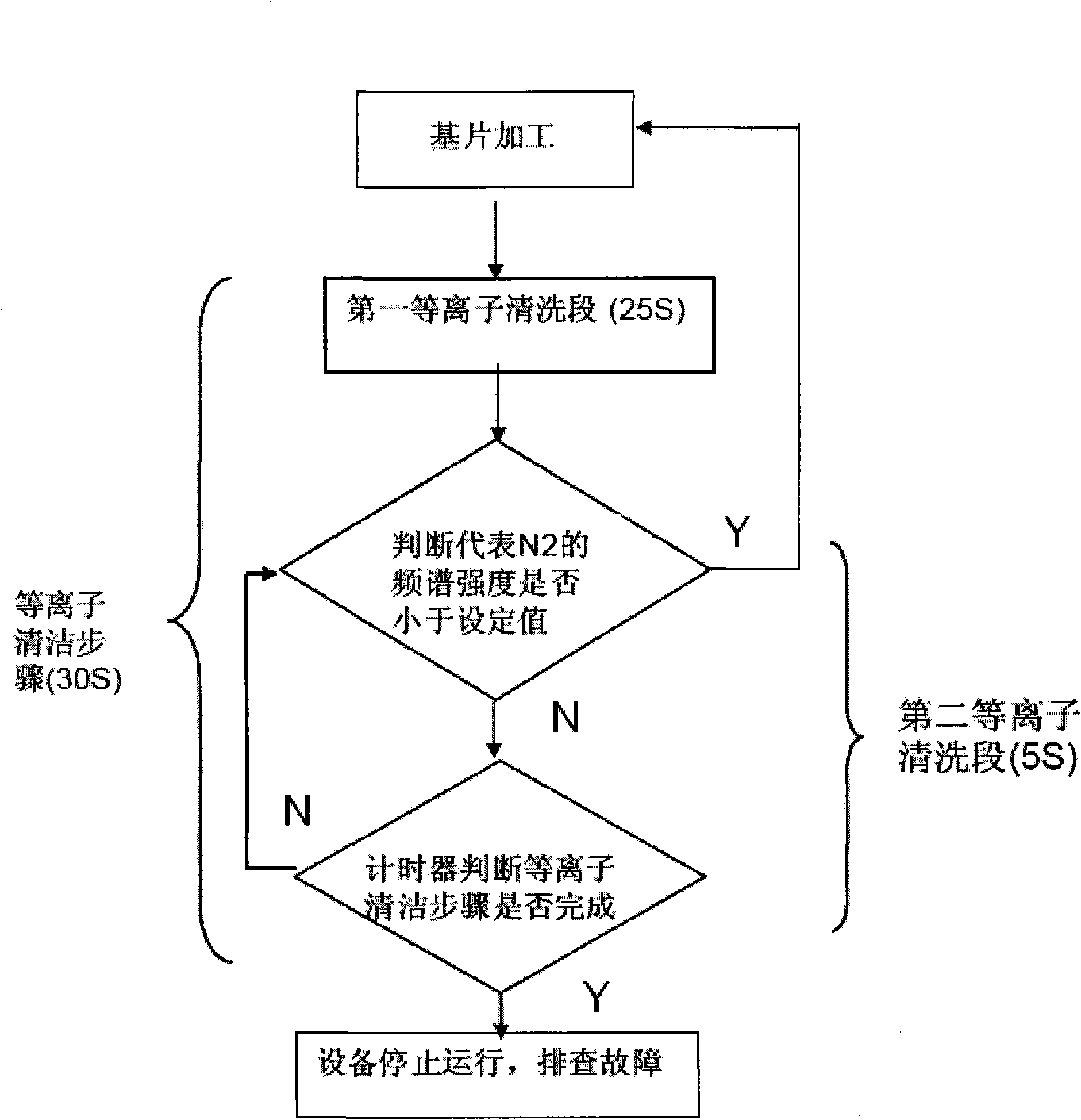

[0018] The invention provides a gas leakage detection method for a vacuum reaction chamber. The vacuum reaction chamber can be a widely used plasma etching or chemical deposition reaction chamber, or other reaction chambers that require a vacuum state. figure 1 It is a typical plasma etching reaction chamber. The reaction chamber includes an outer chamber wall 1, and a gas distribution device such as a shower head 11 on the top of the chamber. The shower head receives the reaction gas from the gas source 110 and distributes it evenly into the reaction chamber At the same time, the gas distribution device 11 also serves as the upper electrode for plasma generation. The lower part of the reaction chamber includes a pedestal 22 on which a processing substrate fixing device 21 is arranged. The substrate fixing device 21 can be an electrostatic chuck (ESC) or other mechanical fixing devices. The substrate 20 is placed on the substrate holding device 21 . An edge ring 23 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com