Novel piston top of gas engine

A piston top and gas engine technology, applied to pistons, mechanical equipment, engine components, etc., can solve problems such as increased fuel consumption, complex structure, and difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

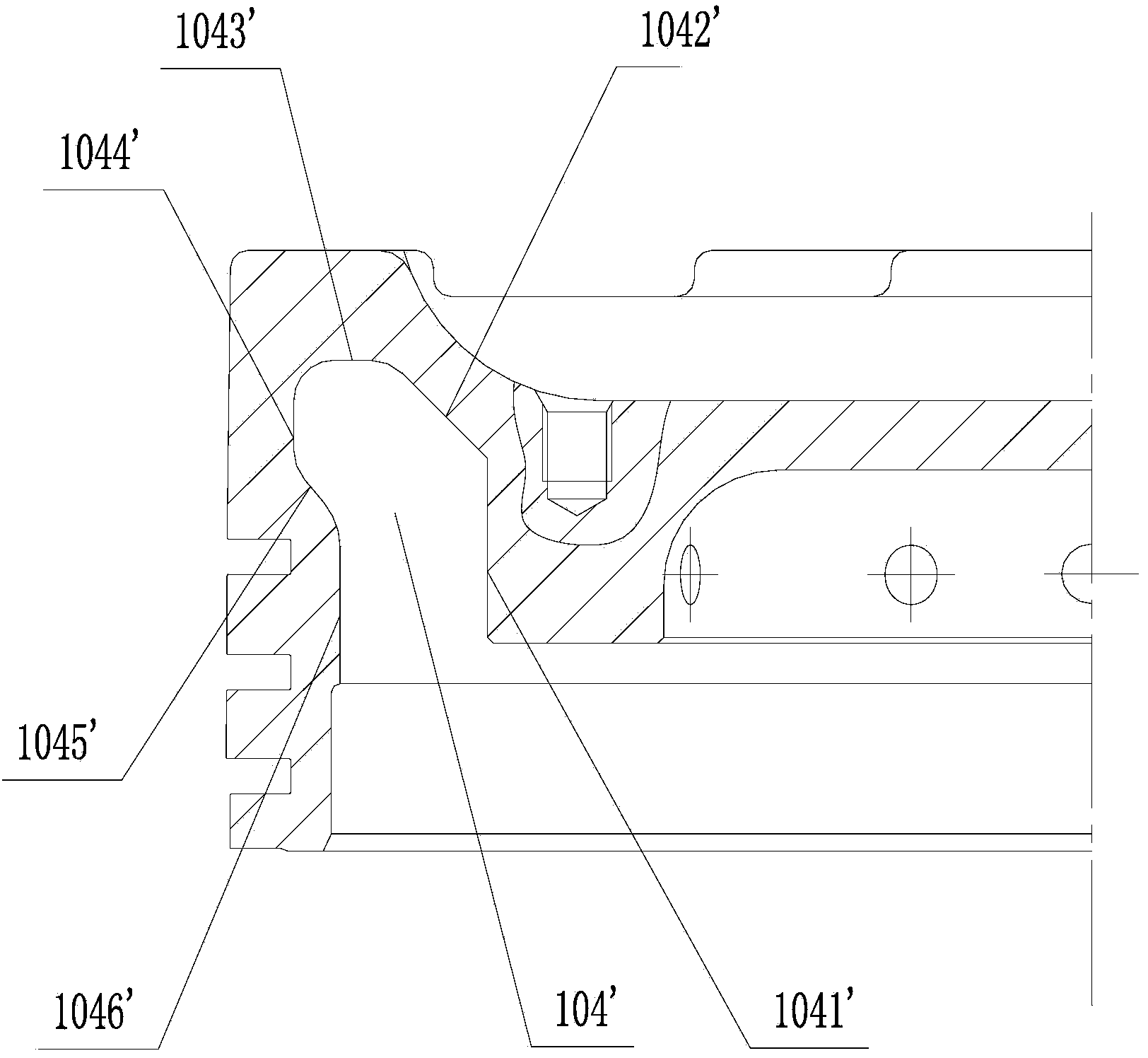

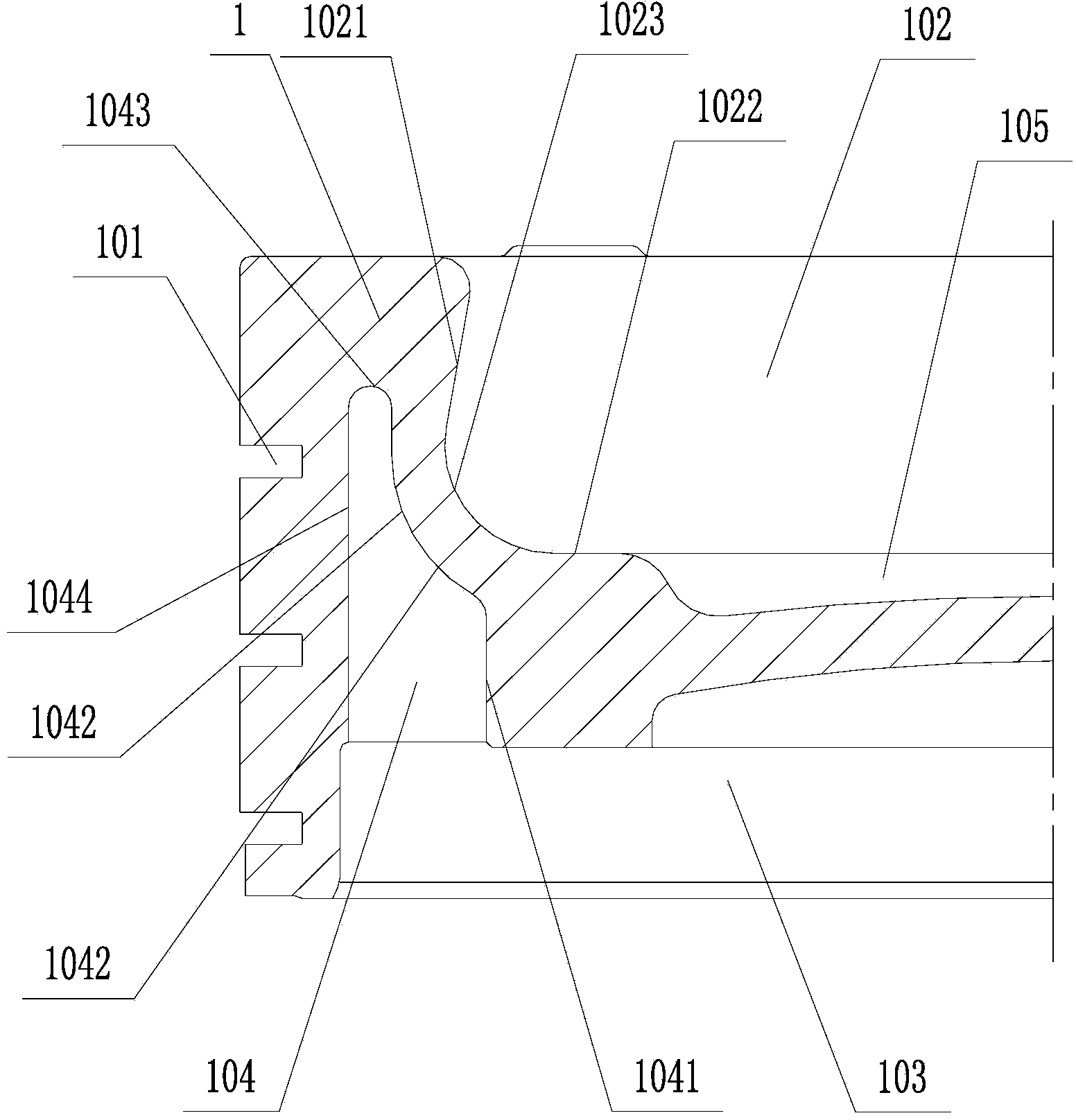

[0017] refer to figure 2 , the present invention provides a novel gas engine piston top, comprising a cylindrical piston top body 1, and the size of the piston top body 1 is There are at least two annular grooves 101 equidistantly distributed along the axial direction on the side wall of the piston top body 1, three in this embodiment. The cross section of the annular grooves is rectangular, and the upper end of the piston top body 1 is concave A first cavity 102 is formed. The first cavity 102 is a conical structure with a small opening and a large bottom surface, and the side wall 1021 of the first cavity 102 is connected to the lower bottom surface 1022 through a first arc surface 1023. In this embodiment Among them, a third cavity 105 is also formed on the lower bottom surface of the first cavity 102. The bottom surface of the third cavity 105 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com