Rapid cooling method and device after medium and thick plate heat treatment furnace

A heat treatment furnace and post-furnace technology, which is applied in the field of fast cooling method and fast cooling device after the heat treatment furnace of medium and thick plates, can solve the problems of increasing equipment investment, etc., achieve the improvement of unit production capacity, moderate cooling speed, and benefit narrow and long workshops The effect of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

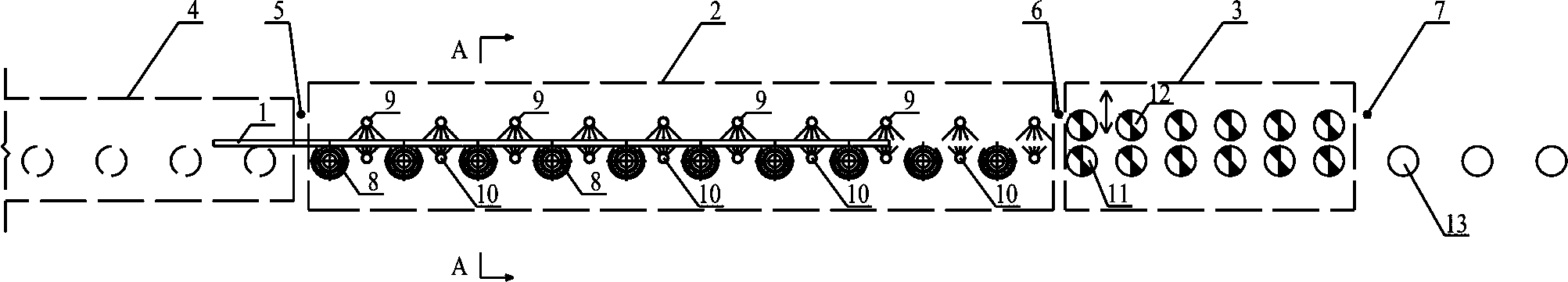

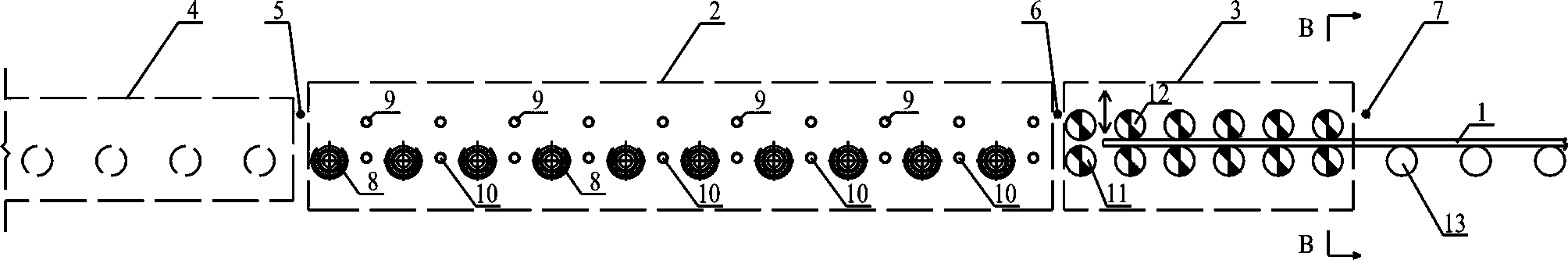

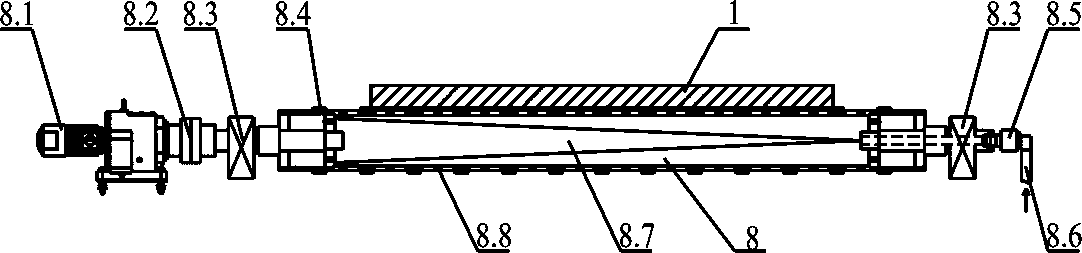

[0026] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] The fast cooling method after the heat treatment furnace for medium and heavy plates in this embodiment is to firstly use the gas injection method to initially cool the steel plate to about 200~450°C during the transportation process of the steel plate after being treated in the heat treatment furnace, and then use contact cooling It is a method to further lower the temperature of the steel plate to about 80~200°C. By adopting the cooling method, not only the cooling time of the steel plate 1 can be greatly shortened, and the production efficiency can be improved, but also a reasonable cooling rate has no adverse effect on the structure and shape of the steel plate 1 .

[0028] Here is an engineering example to illustrate the above rapid cooling method in detail: the steel plate 1 in this example is a medium-thick plate with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com