Low-consumption environment-friendly spring steel water-soluble quenching liquid and quenching process

An environment-friendly quenching liquid technology, applied in quenching agents, manufacturing tools, heat treatment equipment, etc., can solve problems affecting quenching effect, harsh working environment in processing workshops, fire hazards, etc., and achieve appropriate cooling speed and excellent oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

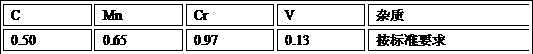

[0033] 1) Material: 50CrVA spring steel, the chemical composition (Wt%) is shown in Table 1, which meets the standard requirements. Material specification 500mmX24mmX90mm, 500mmX25mmX90mm. The single-leaf spring weighs 20-25Kg, and the total weight of the test material is 80 tons.

[0034] Table 1 Chemical composition of experimental materials (mass fraction, %)

[0035]

[0036] 2) In the continuous furnace, uniformly heat the material to the quenching temperature of 800±10°C, and the quenching and heating holding time is 30-45 minutes.

[0037] Prepare the quenching liquid according to the following mass fraction ratio:

[0038] Phenothiazine (or tert-butylhydroquinone), 0.6%; triethanolamine, 1.5%%; preservatives, 0.1%%; methyl silicone oil, 0.2%%; the rest: methoxypolyethylene glycol.

[0039] The quenching liquid and liquid water are proportioned according to the ratio of mass fraction 2:8, and the solution temperature is 20°C. The maximum cooling rate of the quenc...

Embodiment 2

[0042] 1) Material: 50CrVA steel, the chemical composition (Wt%) is shown in Table 2, which meets the standard requirements. Material specification 500mmX20mmX90mm, 500mmX24mmX90mm, 500mmX25mmX90mm. The single leaf spring weighs 10-20Kg, and the total weight of the test material is 200 tons.

[0043] Table 2 Chemical composition of experimental materials (mass fraction, %)

[0044] C

mn

Cr

V

Impurities

0.49

0.60

0.99

0.14

According to standard requirements

[0045] 2) In the continuous furnace, uniformly heat the material to the quenching temperature of 750±10°C, and the quenching plus holding time is 30-40 minutes.

[0046] Prepare the quenching liquid according to the following mass fraction ratio:

[0047] Phenothiazine (or tertiary butyl hydroquinone), 0.61%; triethanolamine, 1.8%; preservatives, 0.2%; methyl silicone oil, 0.25%; the rest: methoxypolyethylene glycol.

[0048] The quenching liquid and liquid water are m...

Embodiment 3

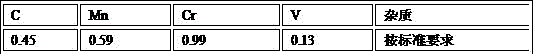

[0051] 1) Material: 50CrVA steel, the chemical composition (Wt%) is shown in Table 2, which meets the standard requirements. Material specification 500mmX16mmX90mm, 500mmX18mmX90mm, 500mmX20mmX90mm. The single leaf spring weighs 10-20Kg, and the total weight of the test material is 200 tons.

[0052] Table 3 Chemical composition of experimental materials (mass fraction, %)

[0053]

[0054] 2) In the continuous furnace, uniformly heat the material to the quenching temperature of 950±10°C, and the quenching holding time is 30-40 minutes.

[0055] Phenothiazine (or N,N'-di-sec-butyl-p-phenylenediamine), 0.65%; triethanolamine, 2.5%; preservatives, 0.35%; methyl silicone oil, 0.3%; the rest: methoxypolyethylene diol.

[0056] The quenching liquid and liquid water are proportioned according to the ratio of mass fraction 3:7, and the solution temperature is 40°C. The maximum cooling rate of the quenching liquid is 120°C / s. After the workpiece is heated to 950±10°C and relea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com