A kind of production method of high-strength graphene-enhanced polyester staple fiber

A technology of polyester staple fiber and production method, which is applied in the field of fiber structure, can solve the problems of low strength of composite fiber structure, and achieve the effects of simple and effective production method, moderate cooling speed and uniform cooling range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

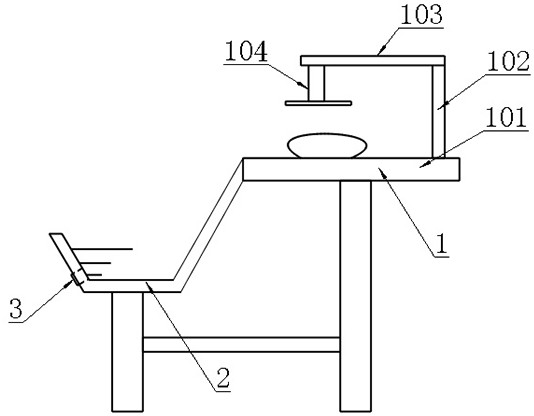

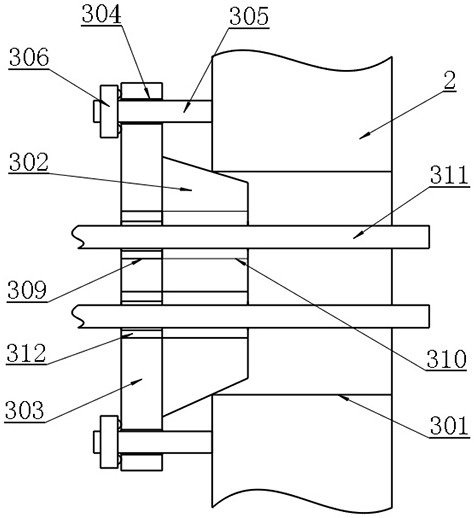

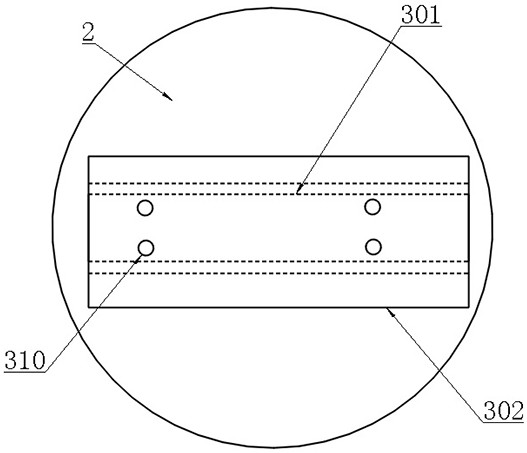

Image

Examples

Embodiment

[0026] Embodiment: a kind of production method of high-strength graphene-enhanced polyester staple fiber, comprises the following steps successively:

[0027] S1, prepare graphene masterbatch;

[0028] S2, melt mixing and granulating described graphene master batch and polyester fiber master batch to obtain mixed master batch;

[0029] S3, the mixed master batch is melted and blended to obtain the final graphene-enhanced polyester staple fiber,

[0030] Wherein, the material composition of the graphene master batch includes graphene powder, aluminum sulfate and ethylene glycol.

[0031] In this embodiment, the polyester fiber master batch adopts existing materials, and in the graphene master batch, the weight ratio of the graphene powder, aluminum sulfate and ethylene glycol is 5:3:2. for mixing and granulation.

[0032] In step S1, the graphene master batch adopts a three-stage zone heating method for heating extrusion and granulation, and the heating temperature is 210-24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com