Method and device for manufacturing amorphous powder

A preparation device and amorphous technology, which is applied in the field of preparation of amorphous powder, can solve the problems of not being able to cool rapidly, hindering the rapid cooling of molten droplets, and not being able to obtain completely amorphous powder, so as to increase the cooling rate and reduce the The effect of oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

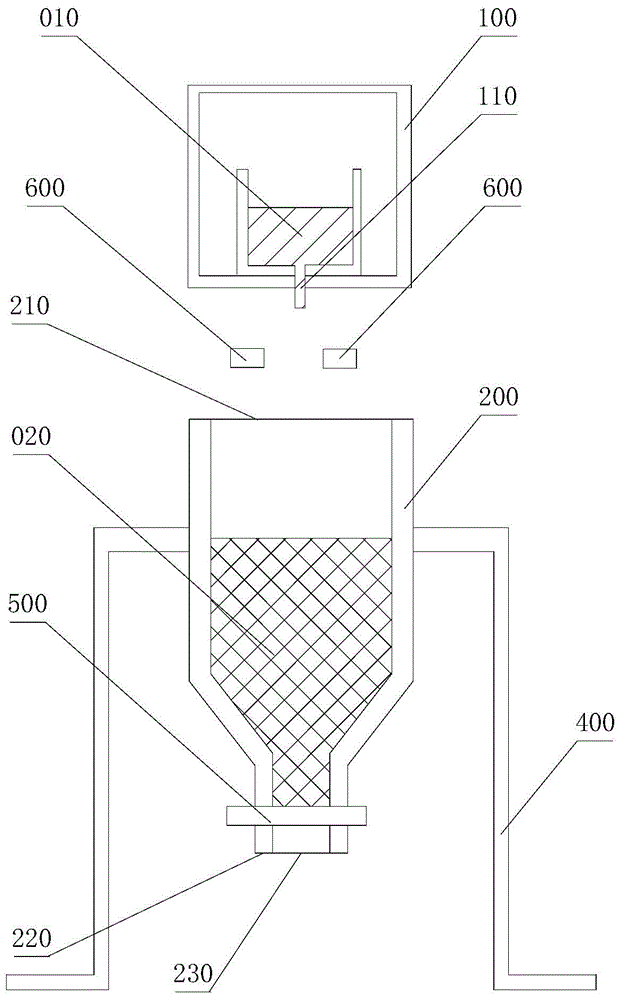

[0037] The invention provides a kind of preparation method of amorphous powder, comprises the steps:

[0038] S100: melting the raw material to obtain a molten liquid; the raw material in this embodiment is an amorphous metal;

[0039] S200: The molten liquid interacts with the atomized gas during the process of flowing out and falling, breaking and dispersing into small liquid droplets;

[0040] S300: Obtain the first fluid after the small liquid droplets move at high speed in water for a certain period of time;

[0041] S400: Collect and separate the first fluid to obtain an amorphous powder.

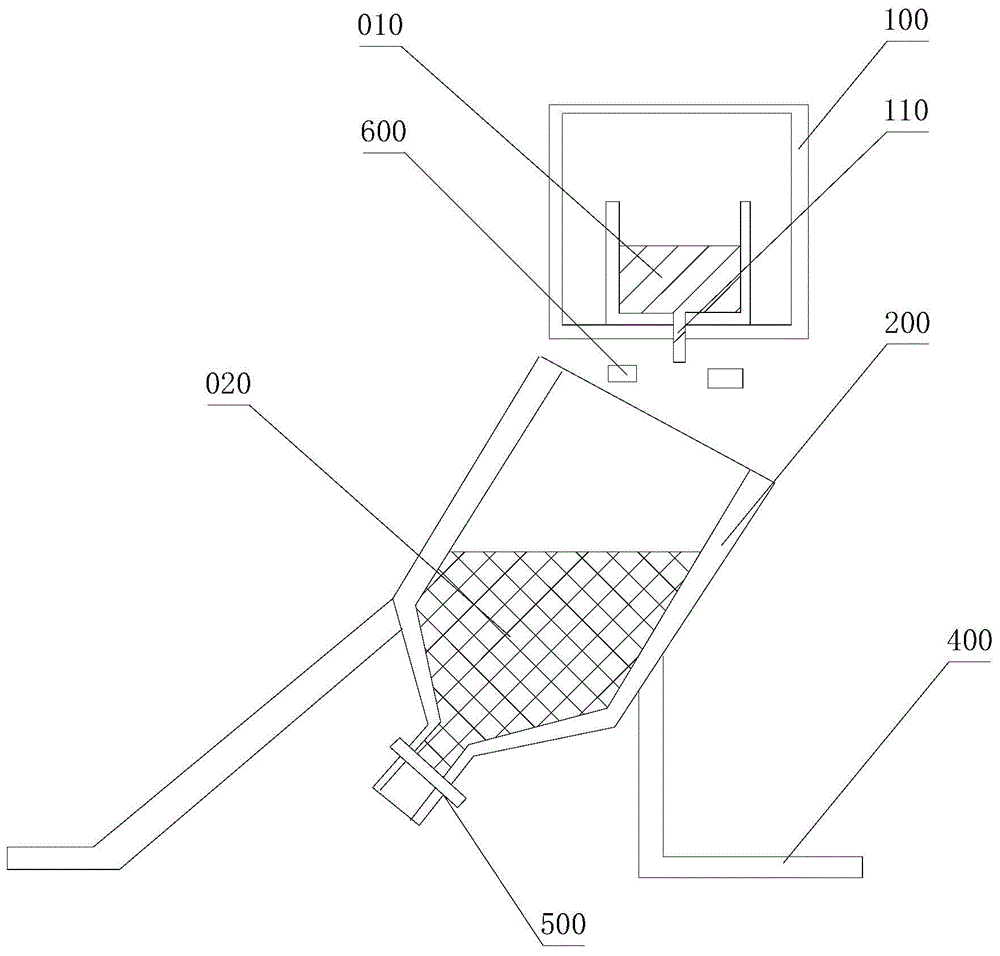

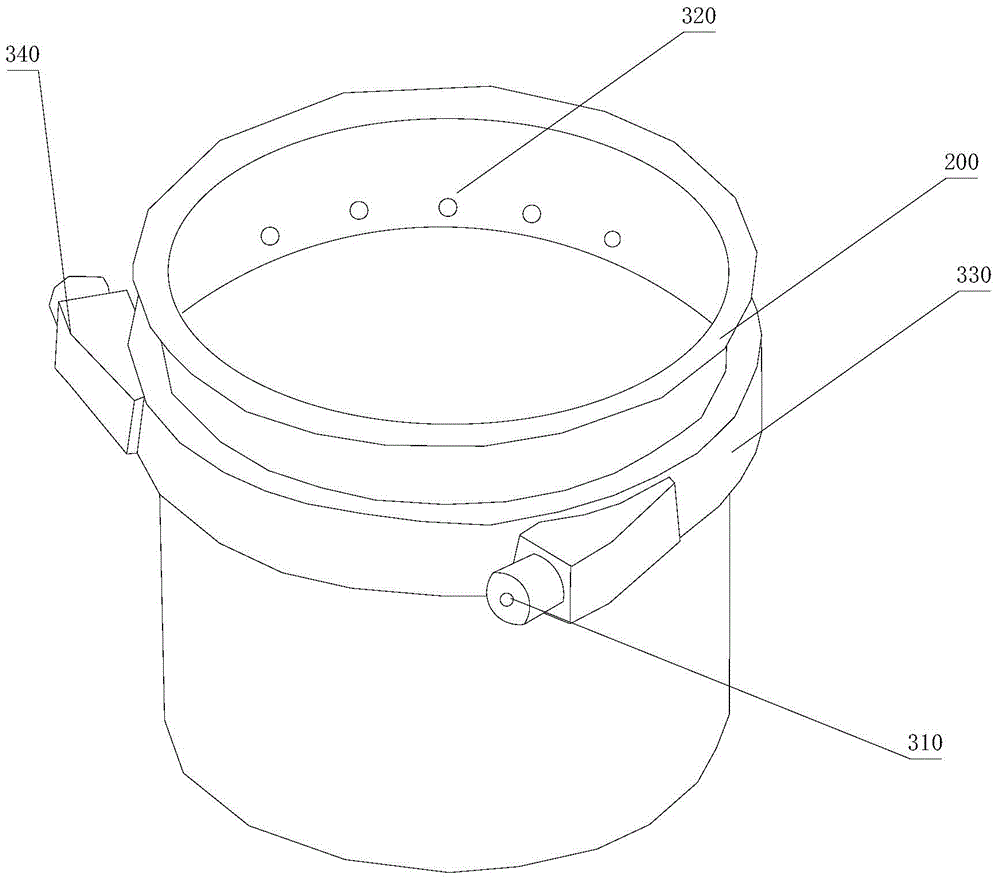

[0042] The present invention adds high-speed motion to the powder preparation method by gas atomization. The basic process is that after the molten metal flows out from the outlet, the atomized gas is used to disperse the molten metal liquid into small liquid droplets, and then the small liquid droplets fall to a In the container, the high-speed movement of the container drives the ...

Embodiment 1

[0063] Using the above preparation device and method to prepare Fe-P-B-Nb-Cr amorphous metal powder, the main process parameters to be controlled and adjusted are: the alloy melt is superheated at 200°C, the melting process is protected by argon, and the gas atomization pressure is 10MPa , The melt flow rate during atomization is 2kg / min, the rotating water injection pressure is 8.5MPa, and the wall of the cylinder is 60° from the falling direction of the molten metal flow.

[0064] The XRD collection of illustrative plates of the Fe-P-B-Nb-Cr powder that makes by above-mentioned parameter is as Figure 5 As shown, there are only diffuse diffuse scattering peaks on its XRD pattern, and there is no obvious crystallization peak corresponding to crystallization, indicating that the prepared powder has an amorphous structure. The scanning electron microscope (SEM) test shows that the amorphous powder has the characteristics of good sphericity, bright surface and few defects. The S...

Embodiment 2

[0066] Using the above preparation device and method to prepare Fe-P-B-Nb-Cr amorphous metal powder, the main process parameters to be controlled and adjusted are: the alloy melt is overheated at 150°C, the melting process is protected by argon, and the gas atomization pressure is 10MPa , the melt flow rate during atomization is 4kg / min, the rotating water injection pressure is 10MPa, the cylinder wall and the falling direction of the molten liquid flow are at 45°, and the cylinder wall rotation speed is 1000 rpm.

[0067] The Fe-P-B-Nb-Cr powder prepared according to the above parameters is detected as an amorphous structure by XRD. The powder has good sphericity, bright surface and few defects. According to the analysis of the laser particle size analyzer, the average particle size of the prepared powder is It is about 50 μm, and the maximum particle size is about 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com