Hot rolled strip laminar cooling device capable of controlling cooled strip shape

A laminar flow cooling device, hot-rolled strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of small cooling rate, cooling asymmetry, cooling area is too long, etc., to achieve high safety , Prevent damage, strong adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

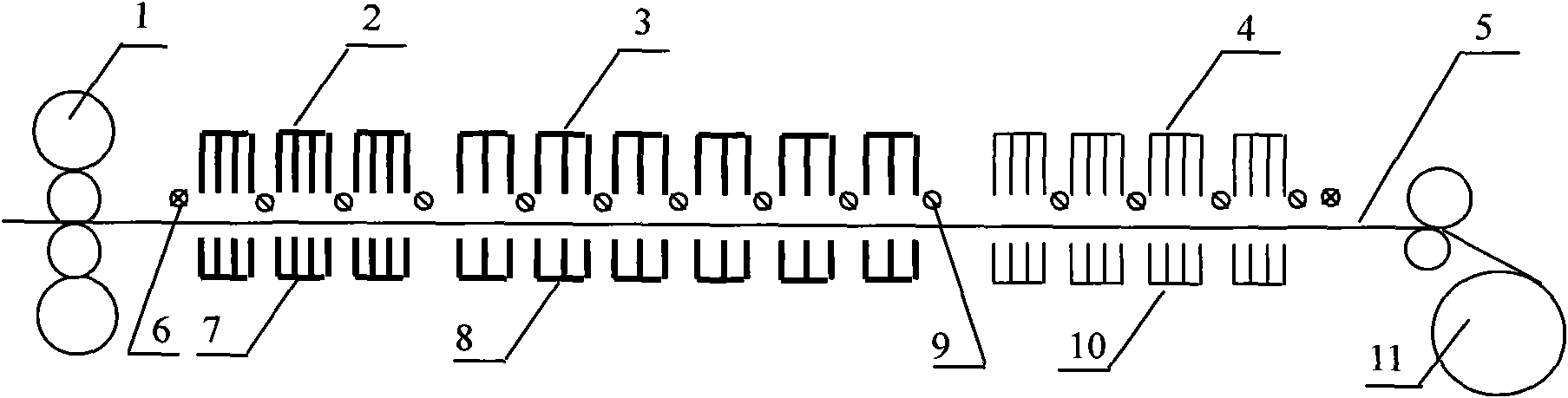

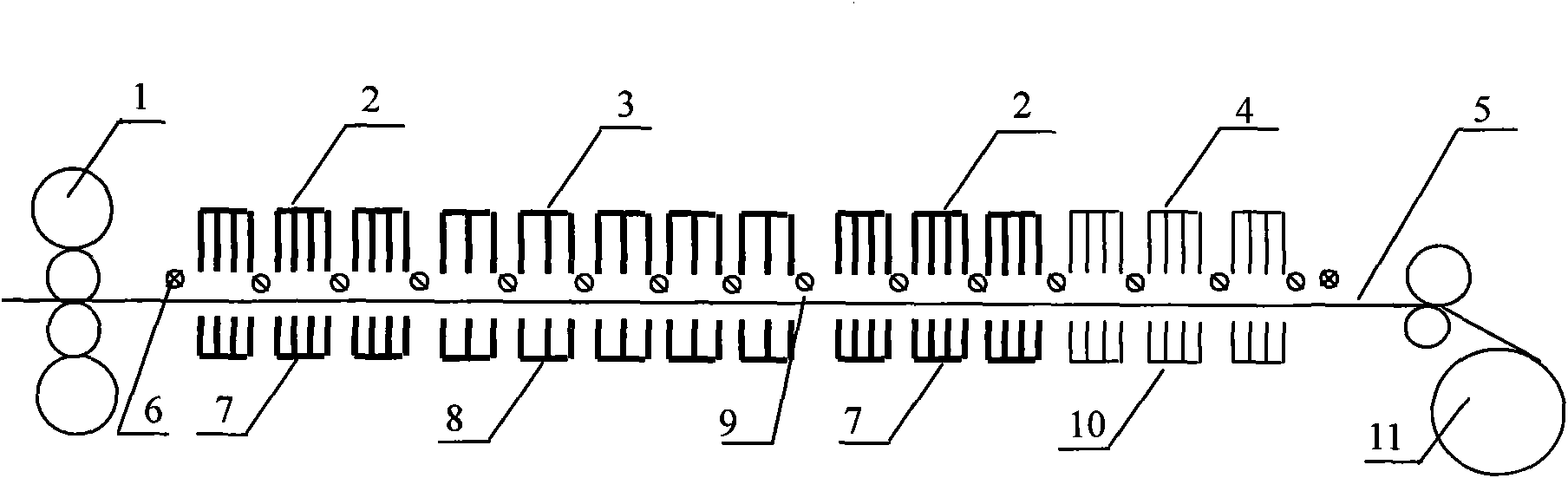

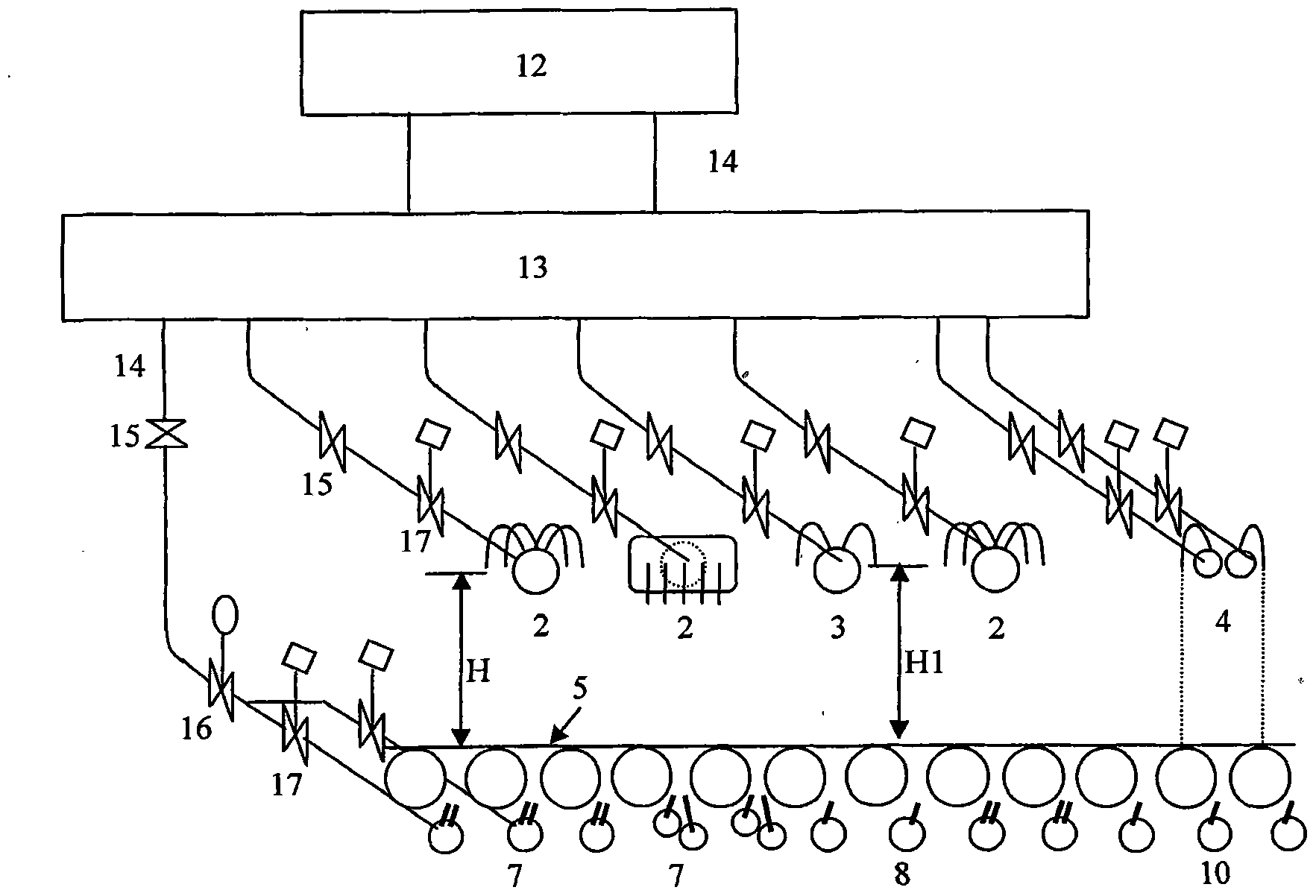

[0034] Attached below Figure 1~5 , the present invention is described in detail as follows:

[0035] A laminar flow cooling device for hot-rolled strip steel with controllable cooling plate shape of the present invention consists of a high-level water tank 12, a water volume distributor 13, a high-density upper header 2, a high-density lower header 7, and a coarse-adjustment and fine-adjustment upper header 3 , 4 and the cooling zone composed of the lower headers 8 and 10 for coarse adjustment and fine adjustment. image 3 It is a connection schematic diagram of a laminar flow cooling device for hot-rolled strip steel with controllable cooling plate shape in the present invention. As shown in the figure, the pipeline 14, the manual valve 15, the flow regulating valve 16, and the pneumatic switch valve 17 respectively connect the water volume distributor 13 and high-density upper header 2, coarse adjustment upper header 3, fine adjustment upper header 4, water volume distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com