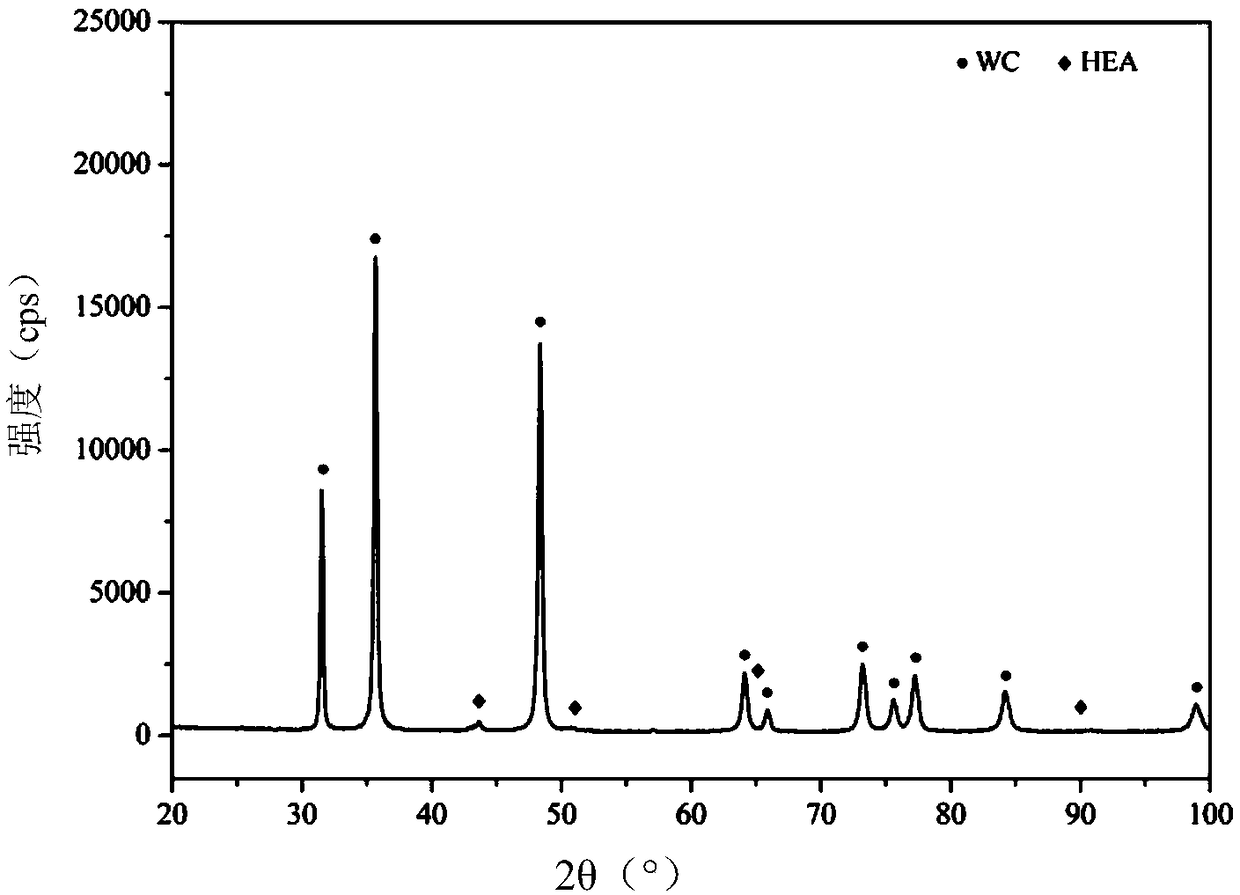

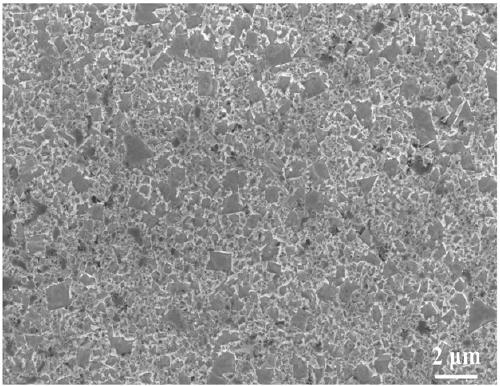

High-entropy alloy binding phase ultrafine tungsten carbide hard alloy and preparation method thereof

A high-entropy alloy and cemented carbide technology, applied in the field of cemented carbide, can solve the problems of losing ultrafine/nanocrystalline features, complex process, toxicity, etc., achieve good comprehensive mechanical properties, reduce Co consumption, and reduce raw material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing high-entropy alloy binder phase ultrafine tungsten carbide cemented carbide, comprising the following steps:

[0030] 1) Weigh Al, Co, Cr, Cu, Fe and Ni powders with a purity greater than 99.9% and an average particle size of less than 45 μm in a molar ratio of 1:1:1:1:1:1, and mix them uniformly Put it into a cemented carbide ball mill jar, and fill it with cemented carbide grinding balls according to the ball-to-material ratio of 10:1, vacuumize the ball mill jar and fill it with high-purity argon; then dry mill at a speed of 300 rpm 40 hours, followed by 2 hours of wet milling (the wet milling medium is ethanol) to obtain high-entropy alloy powder; after the ball milling process is completed, the high-entropy alloy powder is put into a vacuum drying oven and dried at a temperature of 70°C for 48 hours, and Cross 300# sampling sieve, granulate;

[0031] 2) Put 15g of the high-entropy alloy powder of step 1) and 135g of WC powder with a purity g...

Embodiment 2

[0034] A method for preparing high-entropy alloy binder phase ultrafine tungsten carbide cemented carbide, comprising the following steps:

[0035] 1) Weigh Al, Co, Cr, Cu, Fe and Ni powders with a purity greater than 99.9% and an average particle size of less than 45 μm in a molar ratio of 1:1:1:1:1:1, and mix them uniformly Put it into a cemented carbide ball mill jar, and fill it with cemented carbide grinding balls according to the ball-to-material ratio of 10:1, vacuumize the ball mill jar and fill it with high-purity argon; then dry mill at a speed of 300 rpm 40 hours, followed by 2 hours of wet milling (the wet milling medium is ethanol) to obtain high-entropy alloy powder; after the ball milling process is completed, the high-entropy alloy powder is put into a vacuum drying oven and dried at a temperature of 70°C for 48 hours, and Pass 300# sampling sieve, granulate;

[0036] 2) Put 7.5g of the high-entropy alloy powder of step 1) and 142.5g of WC powder with a purity...

Embodiment 3

[0039] A method for preparing high-entropy alloy binder phase ultrafine tungsten carbide cemented carbide, comprising the following steps:

[0040] 1) Weigh Al, Co, Cr, Cu, Fe and Ni powders with a purity greater than 99.9% and an average particle size of less than 45 μm in a molar ratio of 0.5:1:1:1:1:1, and mix them uniformly Put it into a cemented carbide ball mill jar, and fill it with cemented carbide grinding balls according to the ball-to-material ratio of 10:1, vacuumize the ball mill jar and fill it with high-purity argon; then dry mill at a speed of 300 rpm 40 hours, followed by 2 hours of wet milling (the wet milling medium is ethanol) to obtain high-entropy alloy powder; after the ball milling process is completed, the high-entropy alloy powder is put into a vacuum drying oven and dried at a temperature of 70°C for 48 hours, and Cross 300# sampling sieve, granulate;

[0041] 2) Put 15g of the high-entropy alloy powder of step 1) and 135g of WC powder with a purity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com