Novel system for preparing spherical powder through plasma atomization

A plasma and plasma torch technology, which is applied in the field of plasma atomization to prepare spherical powder systems, can solve the problems of low atomization efficiency, easy to wear rotating shaft, limited diameter, etc., so as to save resources, reduce costs, and improve sphericity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

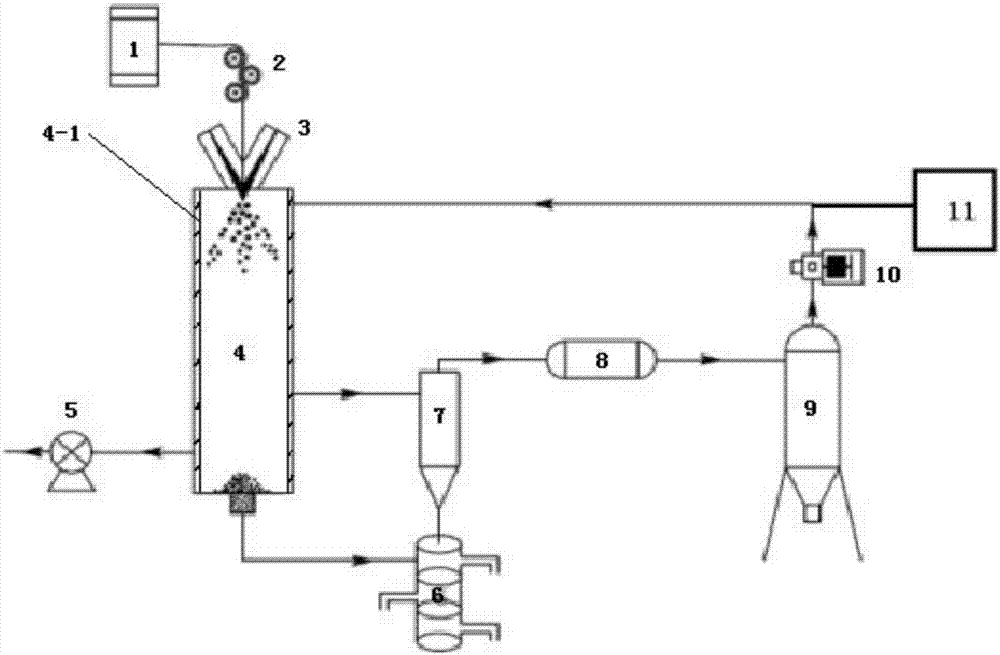

[0033] Such as figure 1 , The plasma atomization preparation spherical powder system in this embodiment includes a feeding device 1, a double-jet plasma torch 3, an atomization tower 4, a vacuum pump 5, an air supply device 11, a cyclone separator 7, a filter 8, The inert gas recovery tank 9 and the gas compression tank 10, the atomization tower 4 are welded by stainless steel plates, and the welds are fixed by tie hoops. The volume needs to be increased or decreased, and each section is equipped with sample collection, observation window devices, temperature measurement and pressure measurement points. The atomization tower includes an inner wall and an outer wall. There is a space between the inner wall and the outer wall to form a water-cooled interlayer 4-1. The water-cooled interlayer is provided with a spiral water-cooled guide groove, and is provided with a water inlet and a water outlet. The water-cooled interlayer passes through deionized water. , Control the wall te...

Embodiment 2

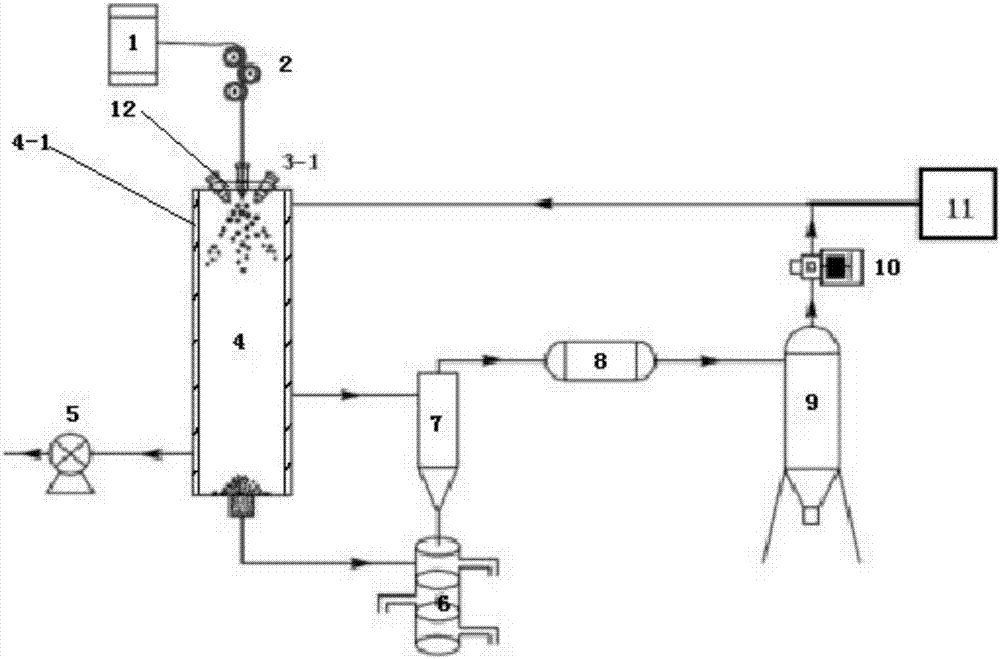

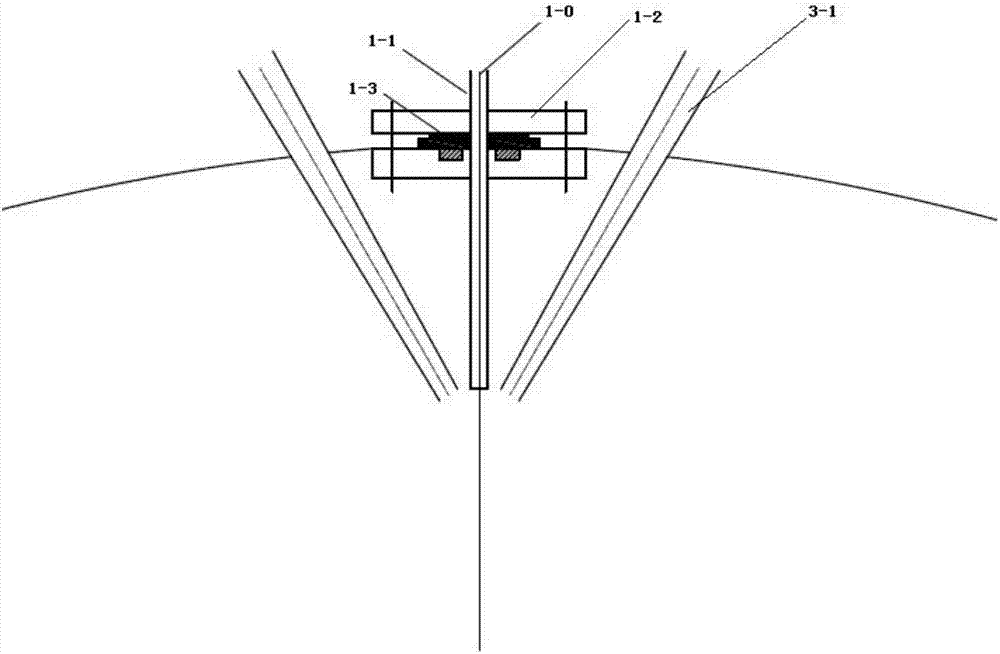

[0037] This embodiment is an improvement made on the basis of Embodiment 1, as figure 2 , the plasma torch selects three laminar flow plasma torches 3-1, installed on the top of the atomization tower 4, and equipped with a plasma torch position adjustment device 12. Plasma torch position adjustment device such as Figure 4 As shown, the position adjustment device includes a spherical sealing joint 12-1, a connecting rod 12-3, a sleeve rod 12-4 and a hydraulic transmission device 12-2, and the plasma torch is installed on the atomization tower through the spherical sealing joint 12-1 4, its tail is connected to the hydraulic transmission device 12-2, the sleeve rod 12-4 is vertically fixed on the atomization tower, and is covered with the corundum casing 1-1, the hydraulic transmission device 12-2, the connecting rod 12-3, Cover bar 12-4 is hinged successively. Through the combination of the sleeve rod 12-4, the connecting rod 12-3 and the hydraulic transmission device 12-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com