Low-cost preparation method of ultrafine-grained high-strength plastic rare earth magnesium alloy

A technology of rare earth magnesium and ultra-fine crystals, which is applied in the field of magnesium alloy processing to achieve the effects of simple and controllable process, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

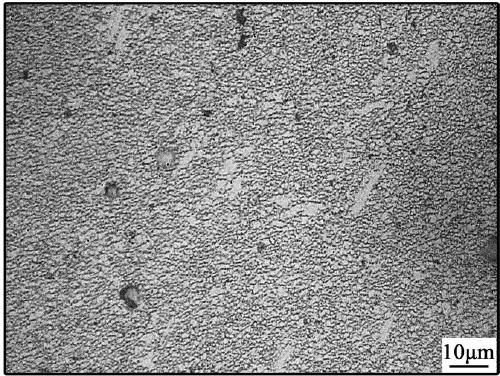

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of the method of the present invention, ZK60-1.2Yb deformed magnesium alloy is used as an example material below, and the present invention will be further described in detail in combination with the description of the drawings and specific implementation examples.

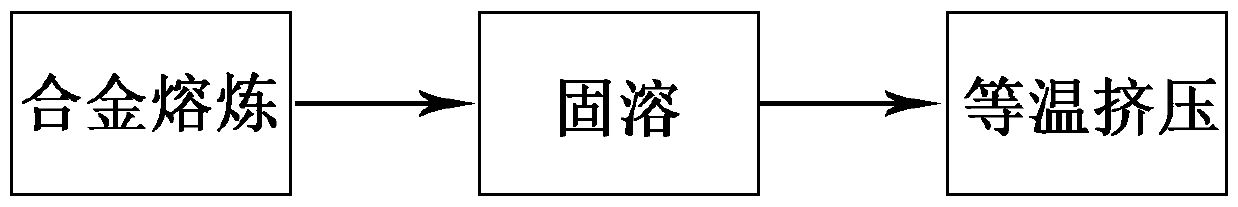

[0022] When preparing ZK60-1.2Yb magnesium alloy, the following methods can be used specifically:

[0023] a. Alloy melting: in SF 6 +CO 2 Under the protection of gas, the magnesium alloy ingredients with the national standard of ZK60 are smelted according to the normal smelting process. After being fully dissolved, the Mg-Yb master alloy with a Yb content of 1.2% of the final smelted alloy design mass percentage is added at 770~780 ºC. Stand at 700~730 ºC for 10~20 minutes to remove slag, then pour out of the furnace and cool naturally to room temperature;

[0024] b. Solution treatment: heat preservation at 400 ℃ and an environment filled with argon for 48 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com