Wrought magnesium alloy containing rare earth cerium and yttrium and having high yield ratio

A technology of deformed magnesium alloy and high yield-strength ratio, applied in the field of magnesium alloy, can solve the problems of uneven processing deformation, difficult regulation, temperature control range error, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

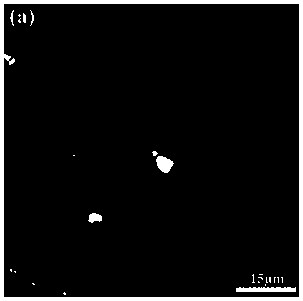

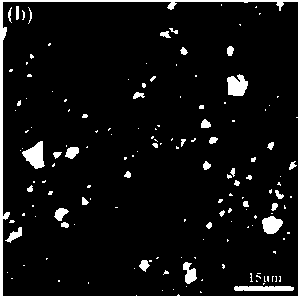

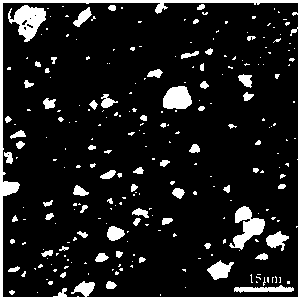

Image

Examples

Embodiment 1

[0032] A high yield ratio deformed Mg-Zn-Zr magnesium alloy containing rare earth cerium and yttrium, comprising the following components by weight percentage:

[0033] Zn 4.98 wt.%, Zr 0.76 wt.%, Ce 0.52 wt.%, Y 0.28 wt.%, unavoidable impurities <0.12 wt.%, the balance is Mg.

[0034] The preparation method of the above-mentioned high yield ratio deformed Mg-Zn-Zr magnesium alloy containing rare earth cerium and yttrium comprises the following steps:

[0035] a) Alloy smelting and casting:

[0036] Raw materials: industrial pure magnesium ingot, pure zinc ingot, Mg-28.54%Zr master alloy, Mg-30%Ce master alloy and Mg-30%Y master alloy.

[0037] Casting by semi-continuous casting method: SF at a volume ratio of 1:99 6 and CO 2 Under the protection of the mixed gas, put the magnesium ingot into the crucible and heat up to 740°C for slag after melting; then add pure zinc ingot and Mg-28.54%Zr master alloy, before adding Preheat the master alloy at 170°C for 25 minutes, quickl...

Embodiment 2

[0045] A high yield ratio deformed Mg-Zn-Zr magnesium alloy containing rare earth cerium and yttrium, including the following components by weight percentage: Zn 5.06 wt.%, Zr 0.57 wt.%, Ce 0.59 wt.%, Y 0.57 wt .%, unavoidable impurities <0.12 wt.%, the balance is Mg.

[0046] The preparation method of the above-mentioned high yield ratio deformed Mg-Zn-Zr magnesium alloy containing rare earth cerium and yttrium comprises the following steps:

[0047] a) Alloy smelting and casting:

[0048] Raw materials: industrial pure magnesium ingot, pure zinc ingot, Mg-28.54%Zr master alloy, Mg-30%Ce master alloy and Mg-30%Y master alloy.

[0049] Casting by semi-continuous casting method: SF at a volume ratio of 5:956 and CO 2 Under the protection of the mixed gas, put the magnesium ingot into the crucible and heat up to 750°C to remove the slag after melting; then add the pure zinc ingot and Mg-28.54%Zr master alloy, before adding the pure zinc ingot and Preheat the master alloy at 1...

Embodiment 3

[0057] A Mg-Zn-Zr high yield ratio deformed magnesium alloy containing rare earth cerium and yttrium, including the following components by weight percentage: Zn 4.97 wt.%, Zr 0.79 wt.%, Ce 0.53 wt.%, Y 1.18 wt .%, unavoidable impurities <0.12 wt.%, the balance is Mg.

[0058] The preparation method of the above-mentioned high yield ratio deformed Mg-Zn-Zr magnesium alloy containing rare earth cerium and yttrium comprises the following steps:

[0059] a) Alloy smelting and casting:

[0060] Raw materials: industrial pure magnesium ingot, pure zinc ingot, Mg-28.54%Zr master alloy, Mg-30%Ce master alloy and Mg-30%Y master alloy.

[0061] Casting by semi-continuous casting method: SF at a volume ratio of 3:97 6 and CO 2 Under the protection of the mixed gas, put the magnesium ingot into the crucible and heat up to 760 ℃ for slag after melting; then add pure zinc ingot and Mg-28.54%Zr master alloy, before adding pure zinc ingot and Mg-28.54%Zr Preheat the master alloy at 140°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com