Patents

Literature

34results about How to "Effective resizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

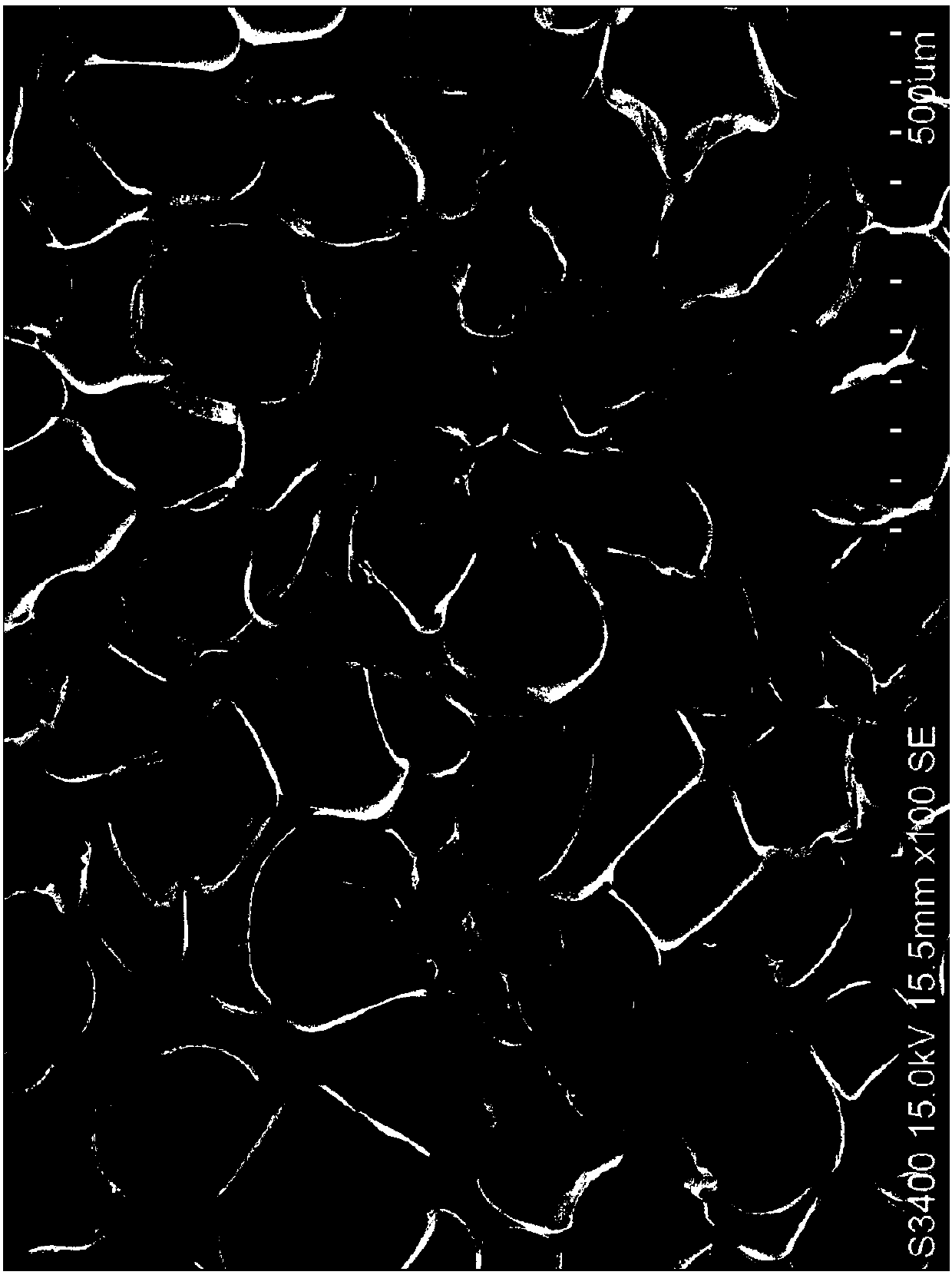

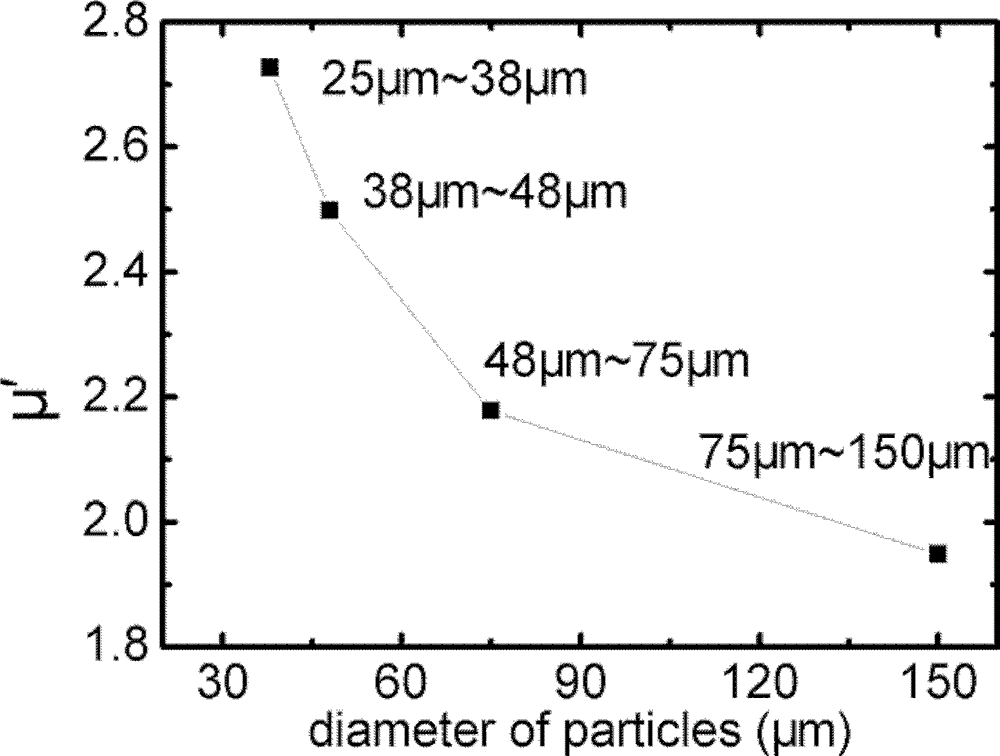

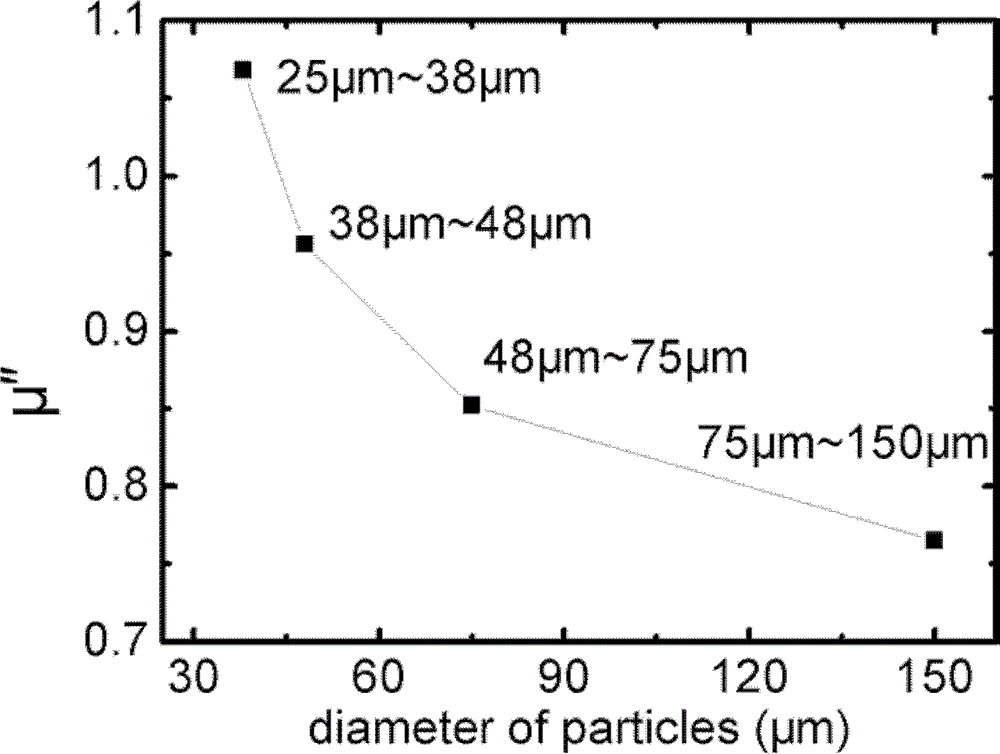

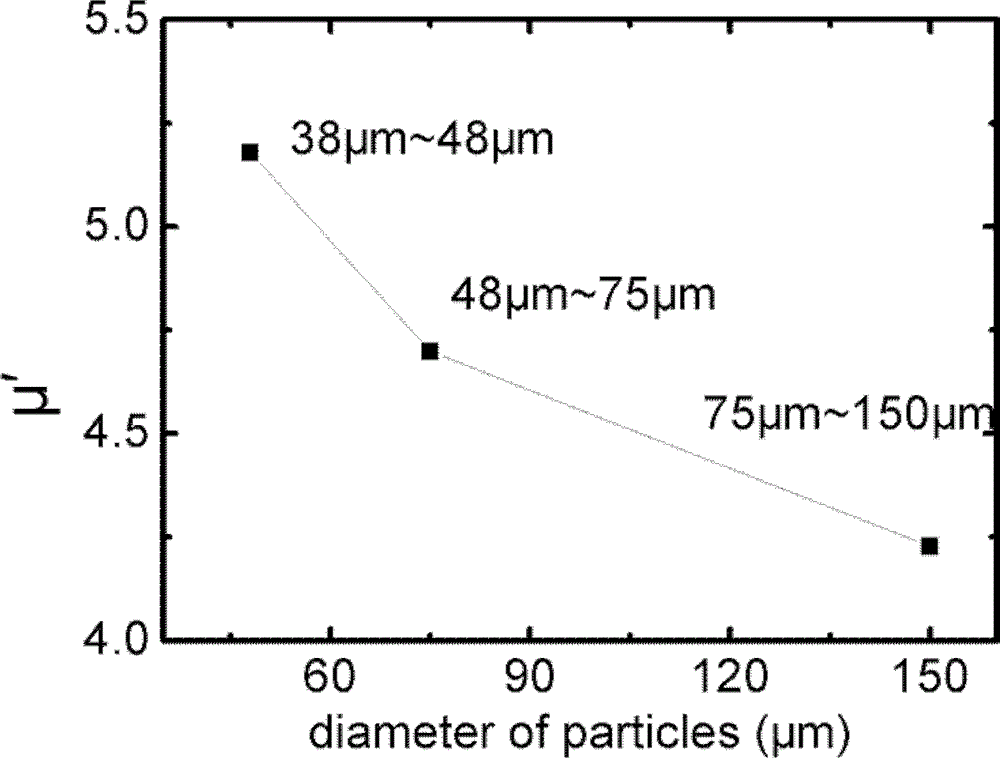

Method for preparing Fe-Si-Al soft magnetic material with high microwave permeability

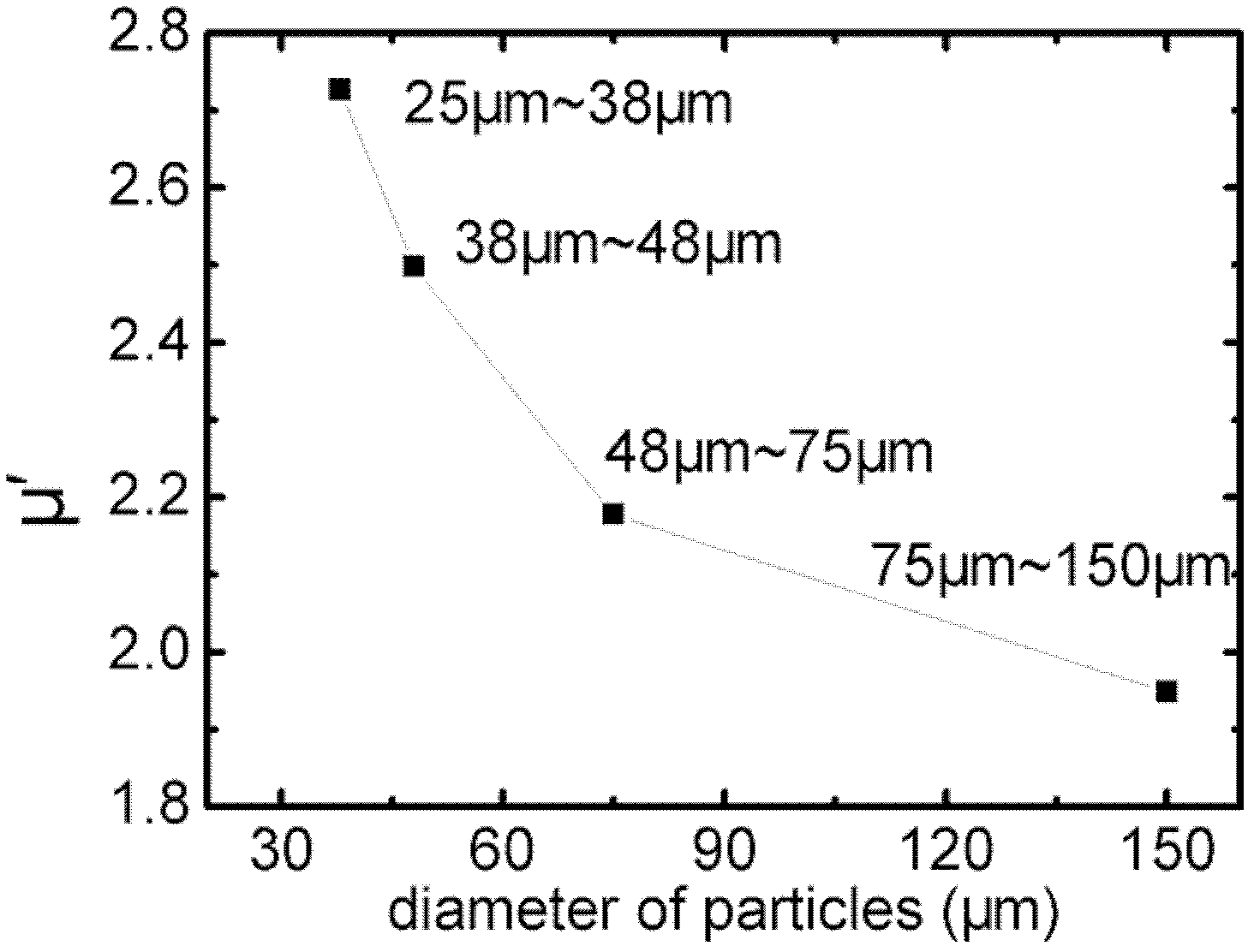

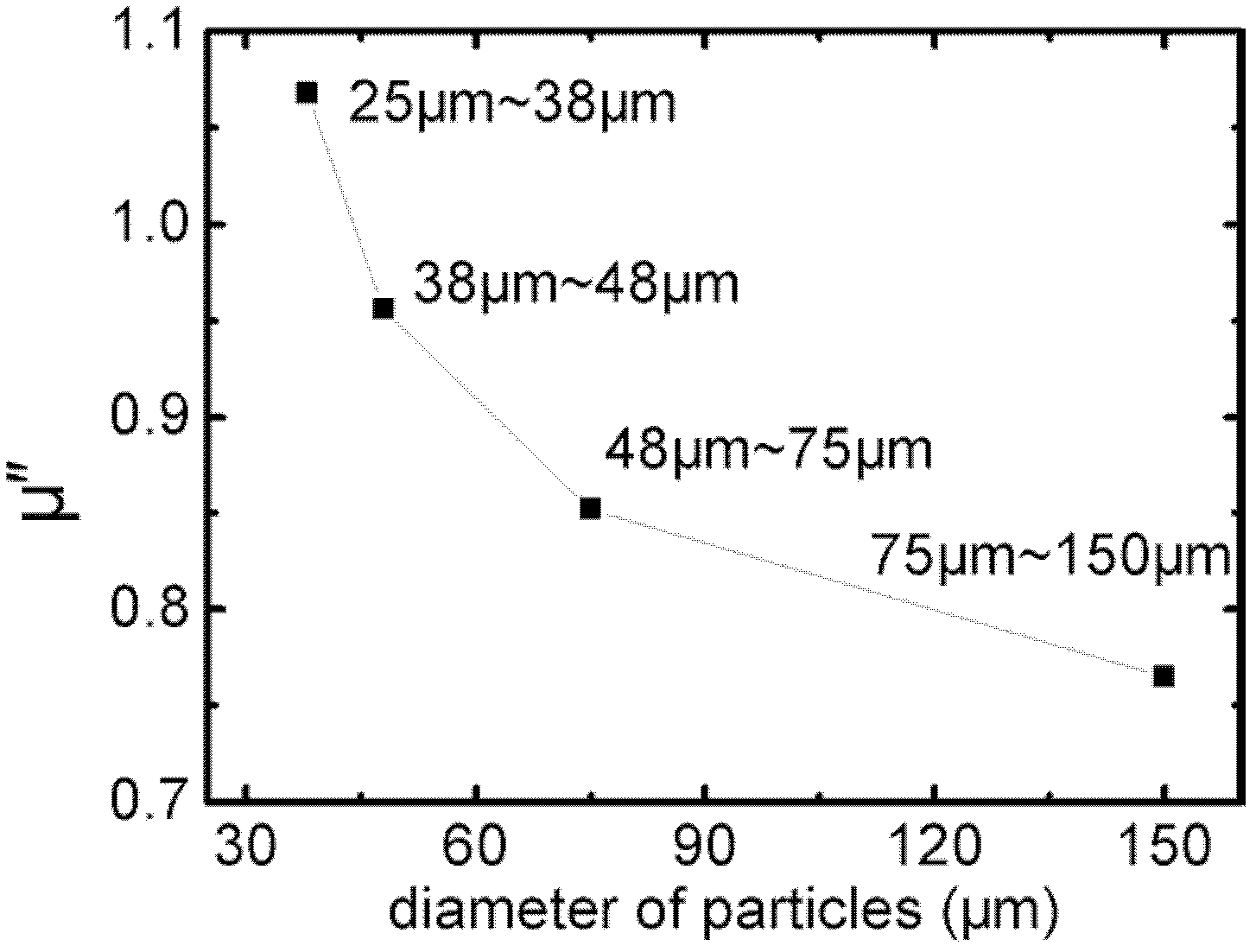

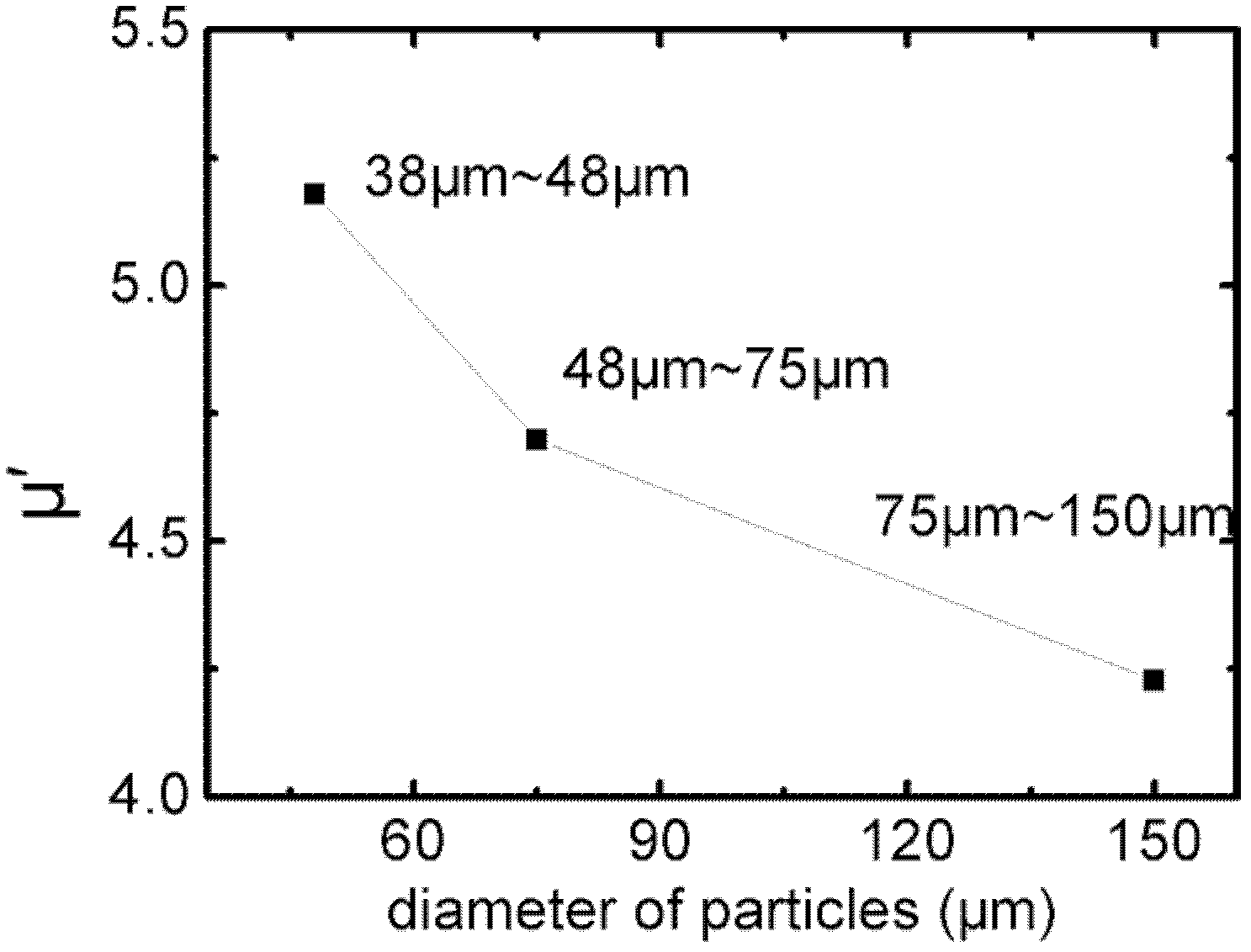

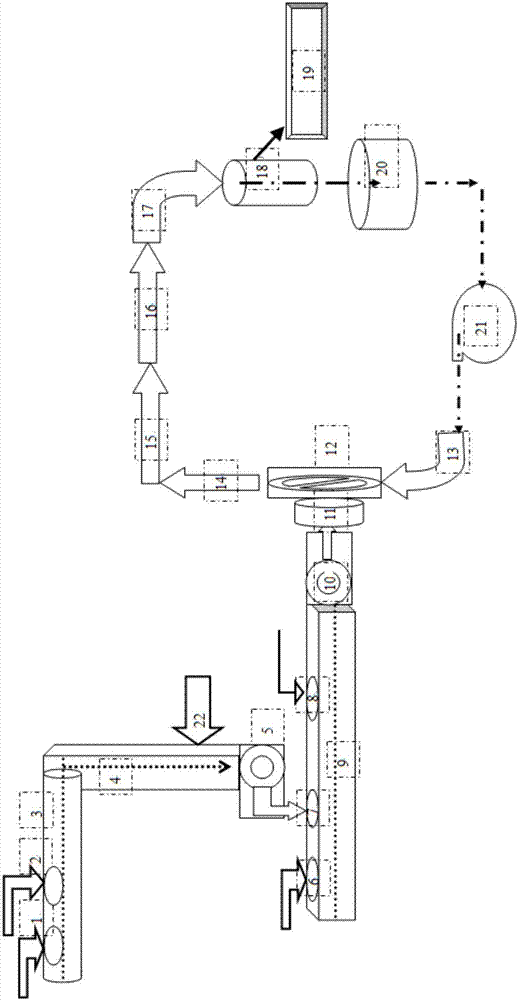

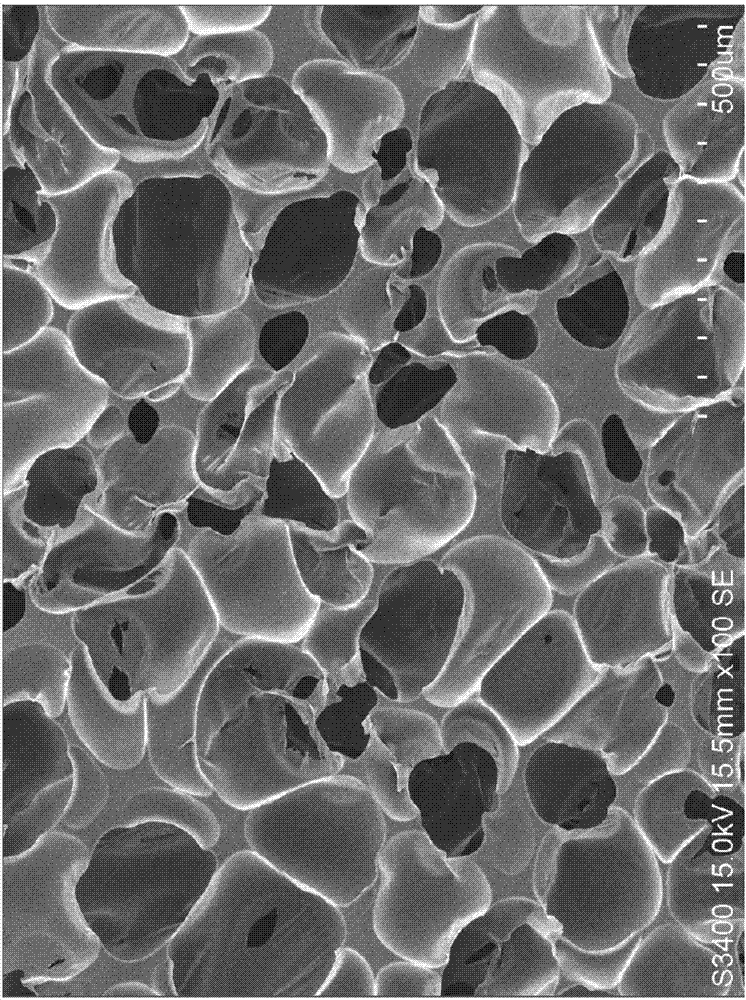

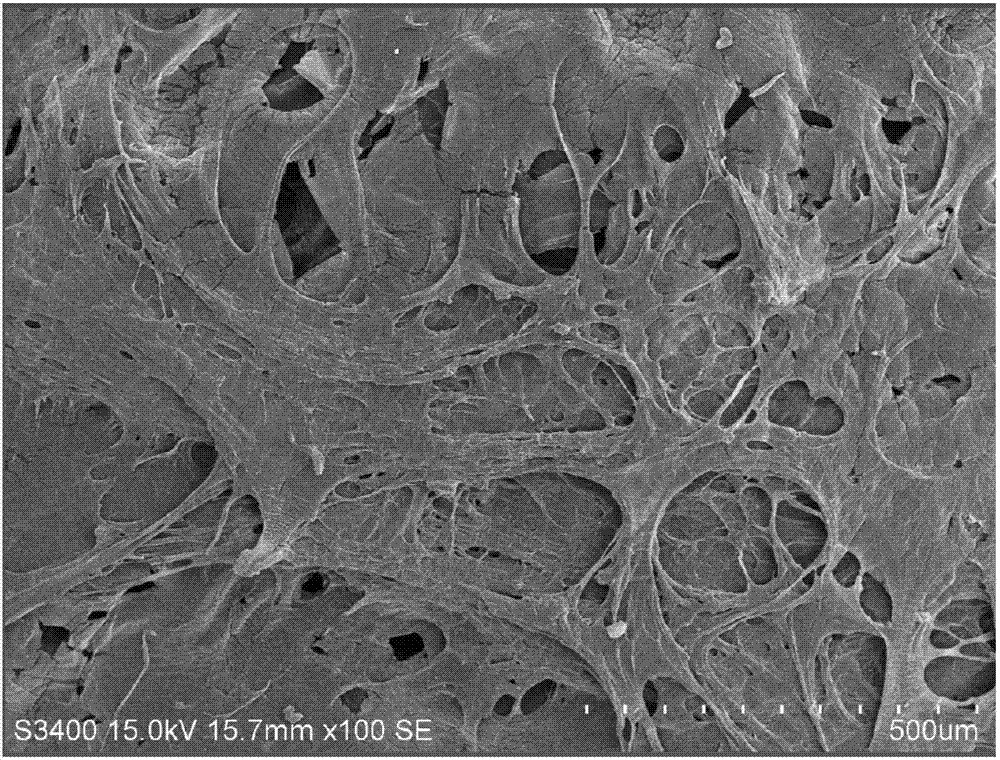

The invention discloses a method for preparing a Fe-Si-Al soft magnetic material with high microwave permeability, belonging to the field of magnetic materials with high-frequency magnetic properties. The method disclosed by the invention comprises the following steps of: (1) sieving 100-mesh Fe-Si-Al raw powder by using a 100-mesh sieve, a 200-mesh sieve and a 300-mesh sieve, wherein the powder being 75-150 microns is called as the A-class powder, and the powder being 48-75 microns is called as the B-class powder, and the Fe-Si-Al raw powder comprises the following components in weight percentage: (82.6-x-7) percent of Fe, (10.3+x) percent of Si and (7.1+y) percent of Al; the absolute value of x is not more than 0.7 and the absolute vale of y is not more than 1.7; (2) carrying out flaky treatment and controlling the ratio of average grain size / thickness of the powder body to be 14-26; and (3) mixing the powder again to obtain the soft magnetic alloy powder body with high microwave permeability according to the mass ratio of the A-class powder to the B-class powder of 0.5-2. The method for preparing the Fe-Si-Al soft magnetic material with high microwave permeability disclosed by the invention has a simple process and is convenient to operate; the Fe-Si-Al alloy powder is sieved before mechanical ball milling, so that the microwave permeability is improved favorably; if the flaky treatment is further carried out, the microwave permeability can be improved by a large margin.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

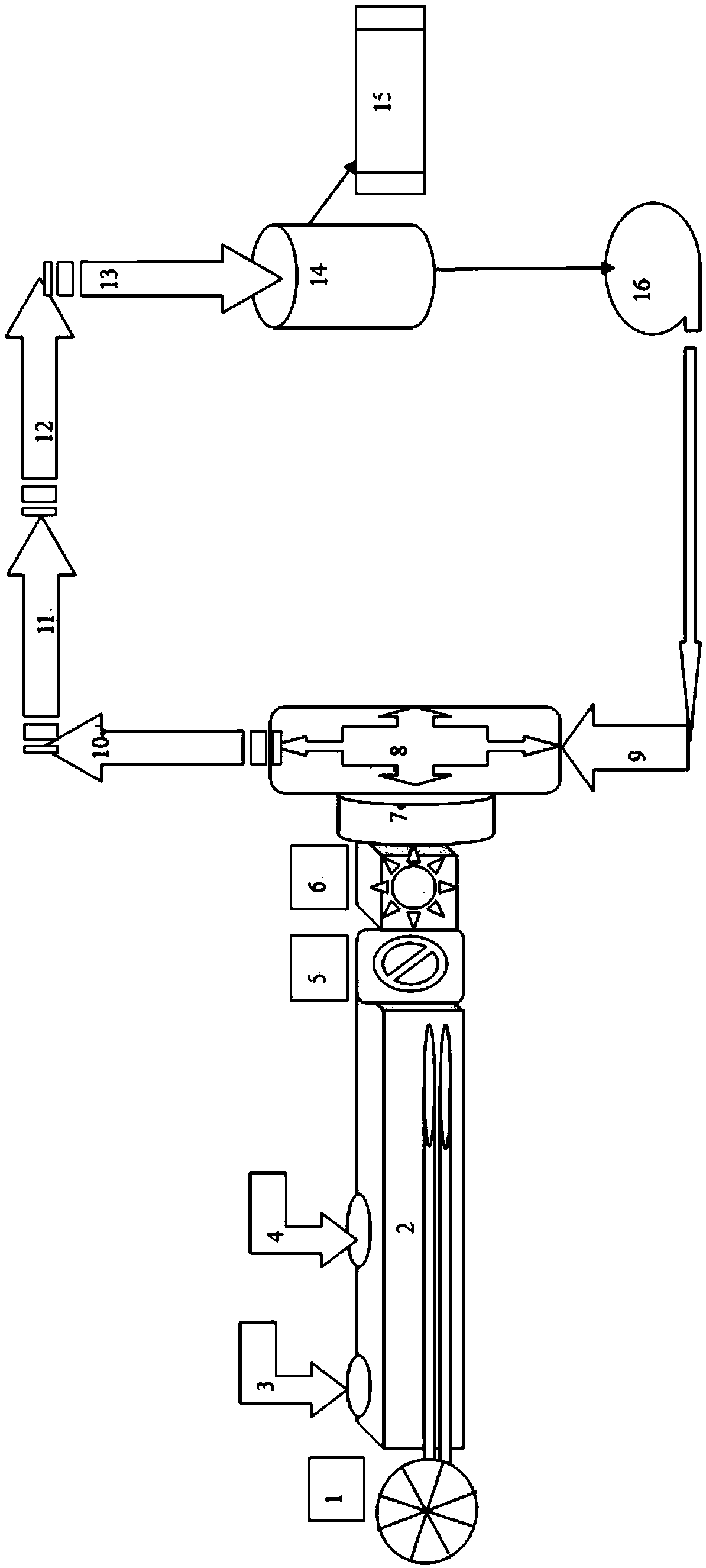

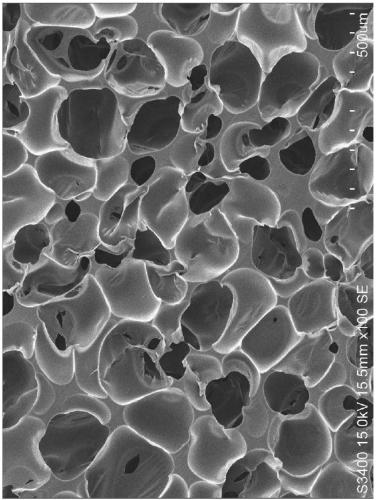

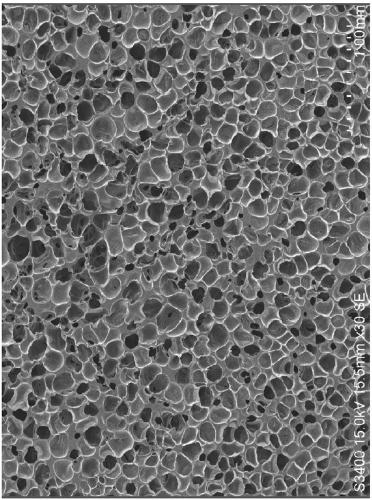

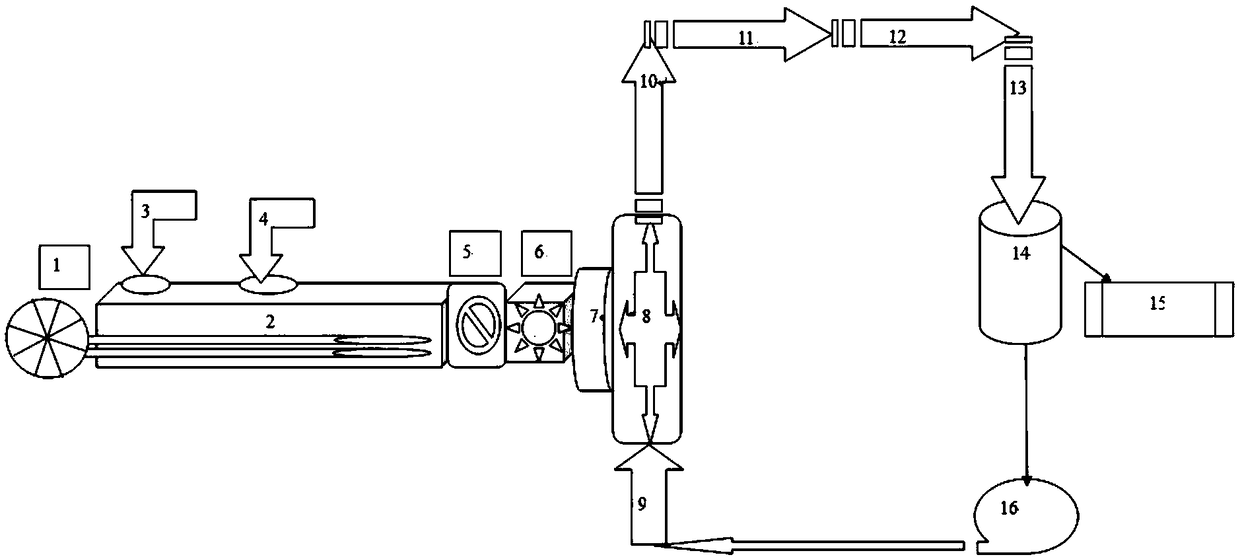

Preparation method of thermoplastic polyurethane micro air bag elastomer material

ActiveCN107383854AReduce dicingReduce energy consumptionChemical/physical/physico-chemical stationary reactorsPolymer scienceHigh pressure

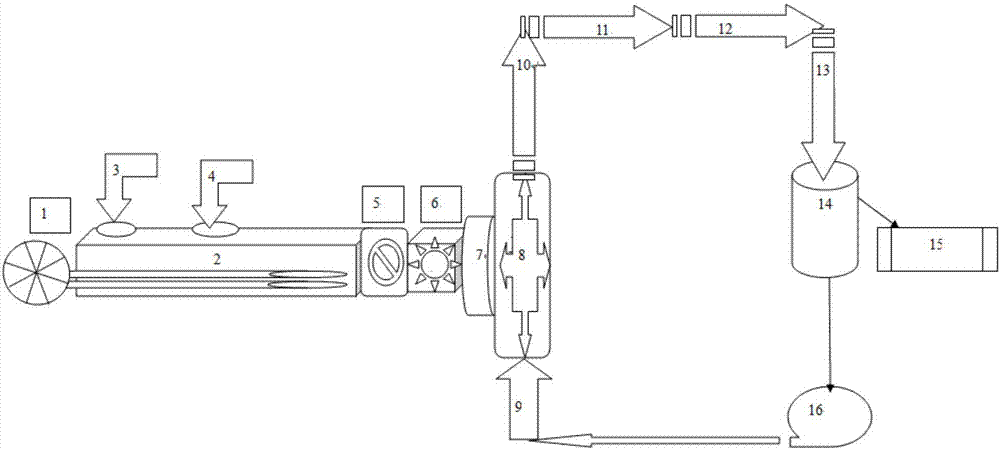

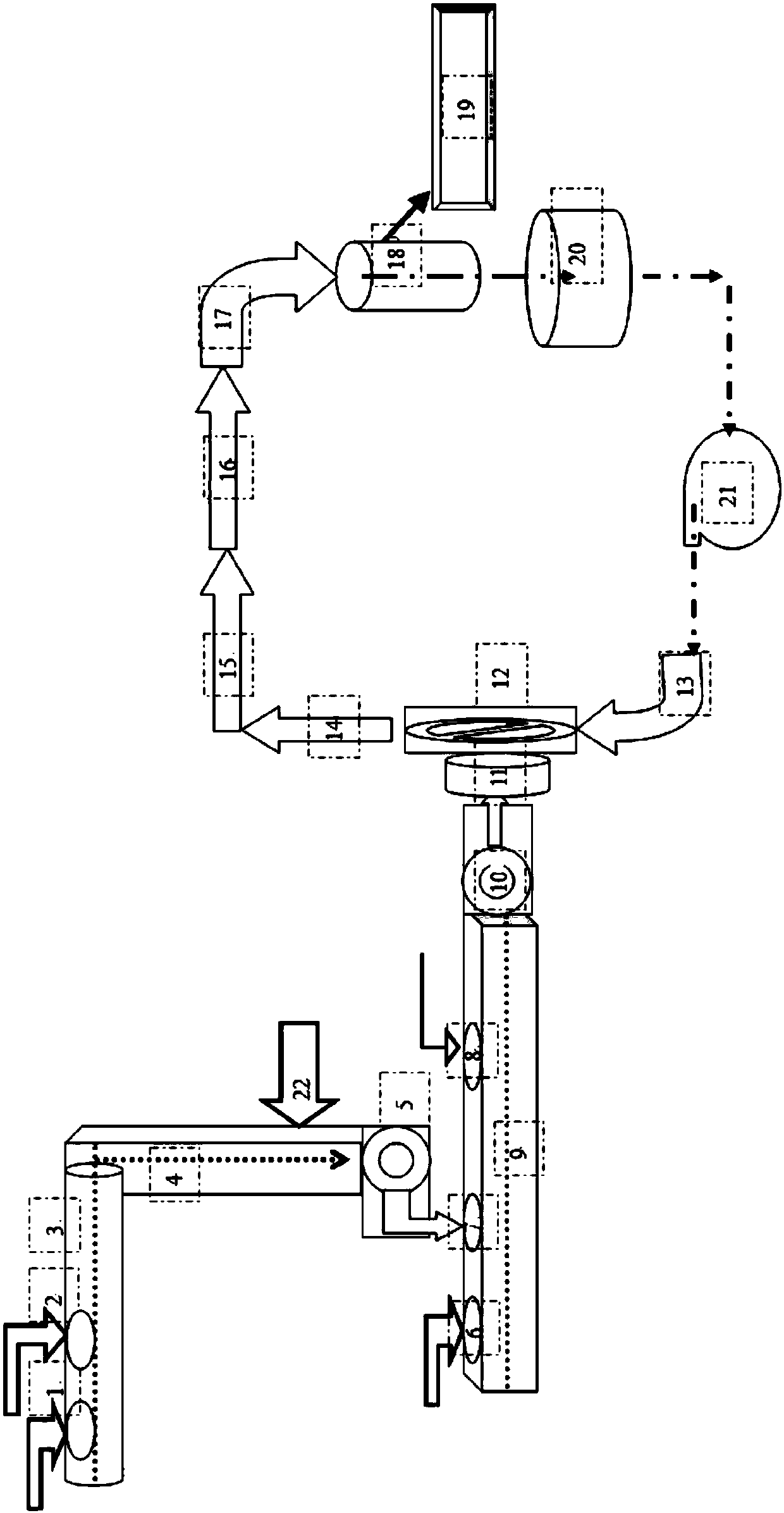

The invention relates to a preparation method of a thermoplastic polyurethane micro air bag elastomer material. The preparation method comprises the following steps of (1) feeding liquid raw materials such as diisocyanate molecules and a solid additive into a twin screw reactor, and carrying out polymerization chain extending reaction to obtain a high molecular weight hot melt; (2) pushing the high molecular weight hot melt into a mixing extrusion molding machine, and carrying out continuous reaction to produce a macromolecular thermoplastic polyurethane melt; (3) continuously adding the obtained macromolecular thermoplastic polyurethane melt, polymer particles and the like in a foaming extrusion molding machine, and then extruding the material from a mold head to an underwater pelletizing chamber in a form of a high-pressure hot melt; and (4) carrying pelletization by process water, sending the pellet-carrying process water to a separation machine by a multi-stage pressure relief and expansion process water pipeline, and carrying out separation, screening and drying to obtain a target product. Compared with the prior art, by adopting the preparation method provided by the invention, the thermoplastic polyurethane elastomer material can be directly prepared from the liquid raw materials such as MDI, so that the energy consumption and the material consumption are greatly lowered, the yield of a product is increased, the production efficiency of the product is improved and the like.

Owner:NANTONG DE NEW MATERIAL CO LTD

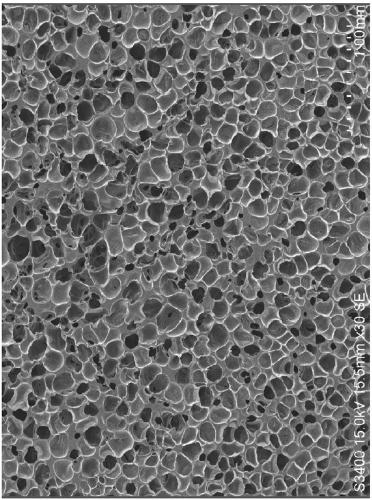

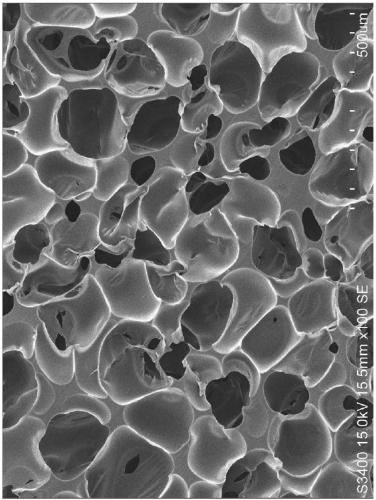

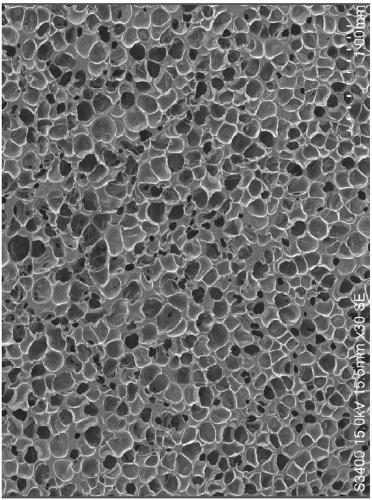

Degradable antifouling thermoplastic micro-airbag polymer elastomer material and preparation thereof

The invention relates to a degradable antifouling thermoplastic micro-airbag polymer elastomer material which is prepared from the following ingredients in percentage by weight: 88 to 98% of polymer raw material, 0.05 to 0.5% of nucleating agent, 0.4 to 2% of foaming agent and 0.1 to 10% of environment-friendly degradable organic perfluorosebacamidine material. A preparation method specifically comprises the steps: (1) feeding the polymer raw material, the nucleating agent and the environment-friendly degradable organic perfluorosebacamidine material from a feeding opening in the front end of a twin-screw extruder, feeding the foaming agent from a feeding opening in a middle section of the twin-screw extruder, hot melting and fully mixing all the raw materials, then sending into a static mixer to be further homogenized and then controlling pressure and quantitatively conveying by a melt pump; (2) sending hot melt sent out by the melt pump into an underwater pelletizing chamber to be pelletized, bringing out by technological water to be separated and screening and drying the particles to obtain a target product. Compared with the prior art, the degradable antifouling thermoplastic micro-airbag polymer elastomer material disclosed by the invention effectively achieves performance of antifouling, soiling-resistant, oil-resistant, contamination-resistant, attractive and good touch and is especially suitable for being applied to the fields of shoe materials, food package and the like.

Owner:NANTONG DE NEW MATERIAL CO LTD

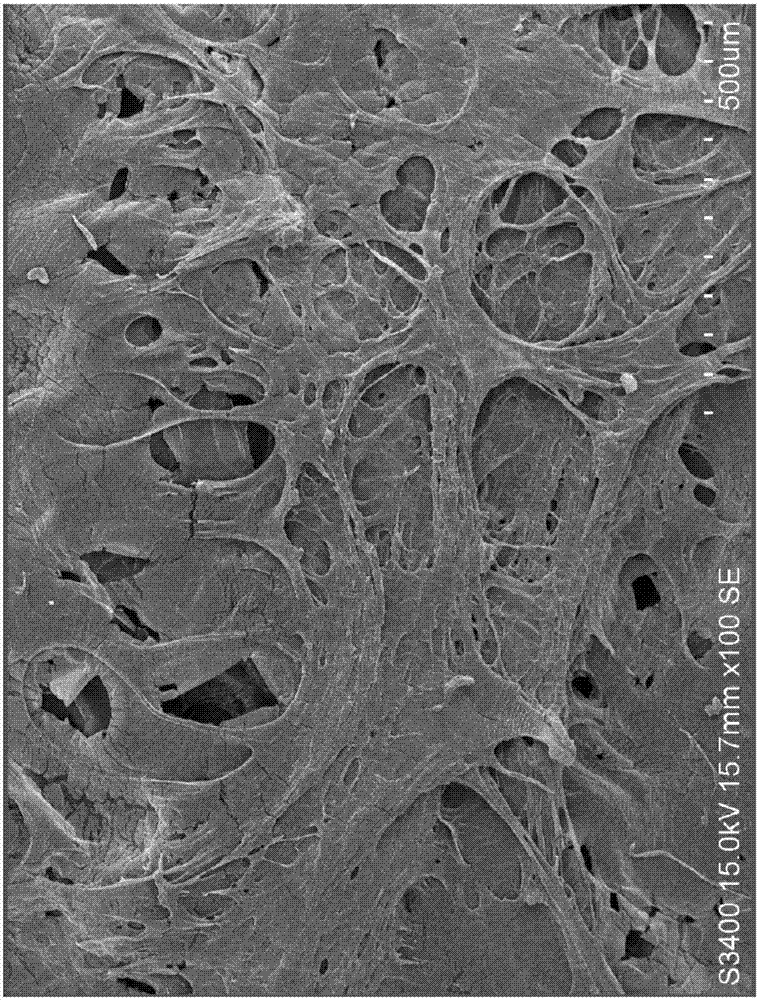

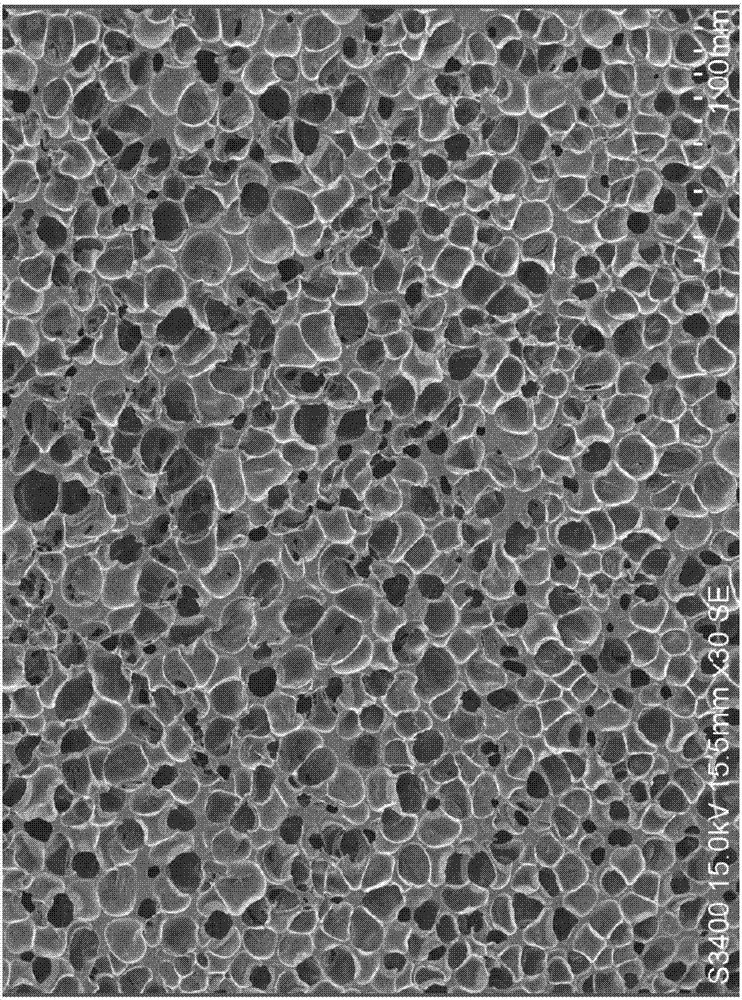

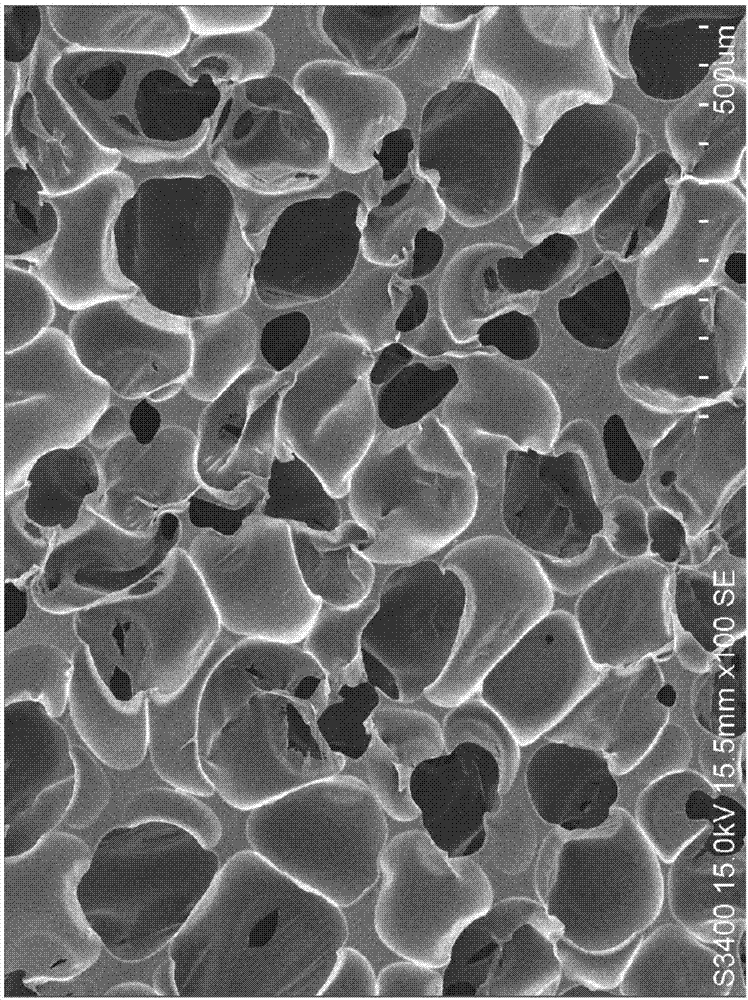

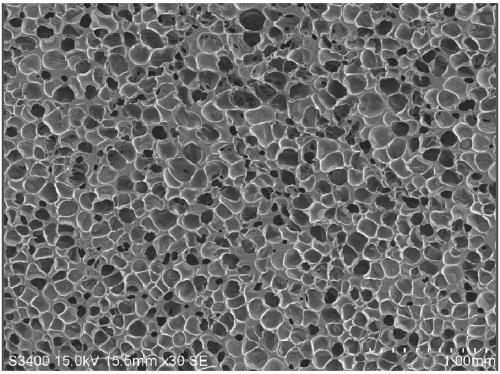

Thermoplastic micro-sac polymer elastomer material and preparation method thereof

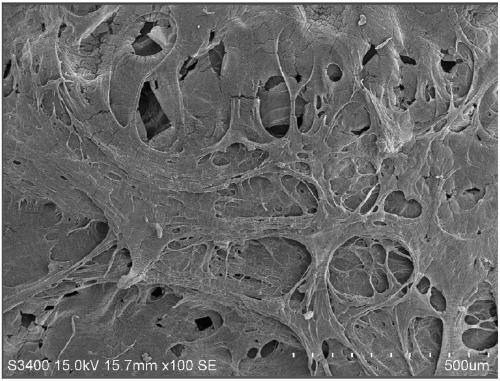

The invention relates to a thermoplastic micro-sac polymer elastomer material and a preparation method thereof. The material is prepared from the following components in percentage by weight: 0.1-97 percent of a support frame polymer material, 0.1-97 percent of pressure-resistance slow-rebound polymer material, 0.01-0.5 percent of a nucleating agent, and 0.1-10 percent of a foaming agent, wherein the support frame polymer material is a high-molecular-weight, high-hardness, high-crystalline or high-polarity polymer material; the pressure-resistance slow-rebound polymer material is a low-molecular-weight, low-hardness, low-crystalline to no irregular shape, low-polarity / no-polarity polymer material. Compared with the prior art, the material has the advantages that a winding network formed by the micro-sac structure and opening pores achieves an interpenetration structure, the rebound force and other material physical performance are excellent, buffer feedback is quick, contact and comfortable performance are high, exfoliated volume is controllable and the like.

Owner:NANTONG DE NEW MATERIAL CO LTD

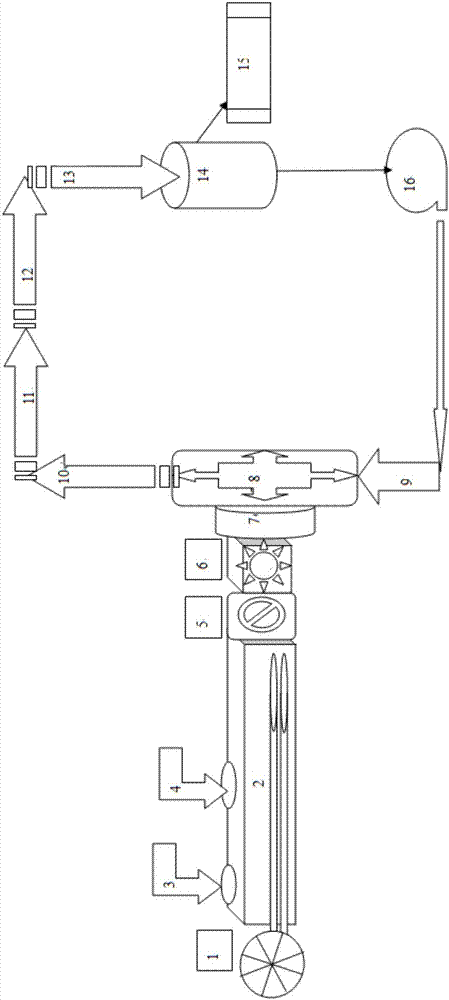

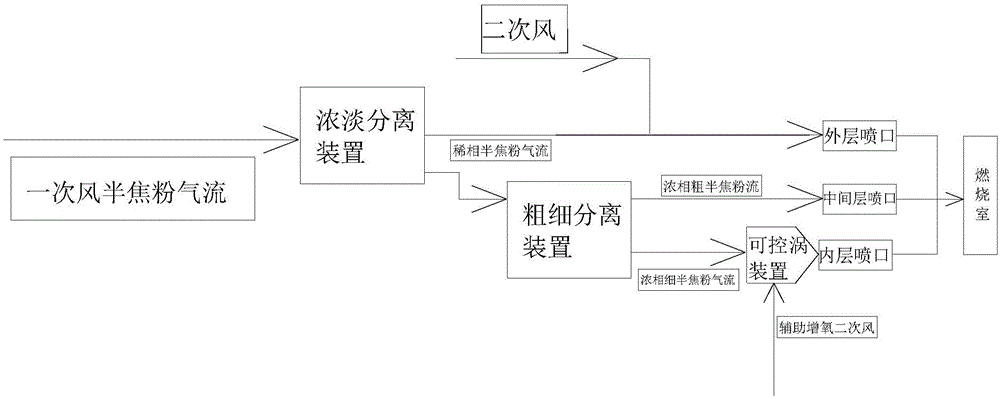

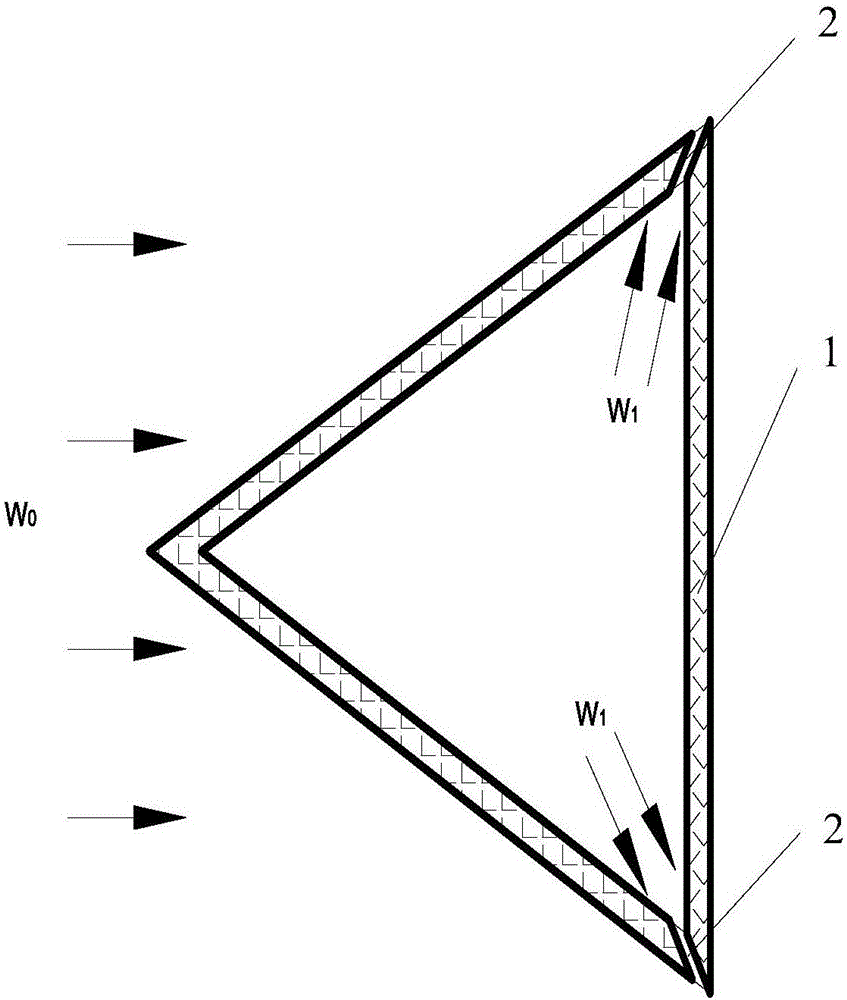

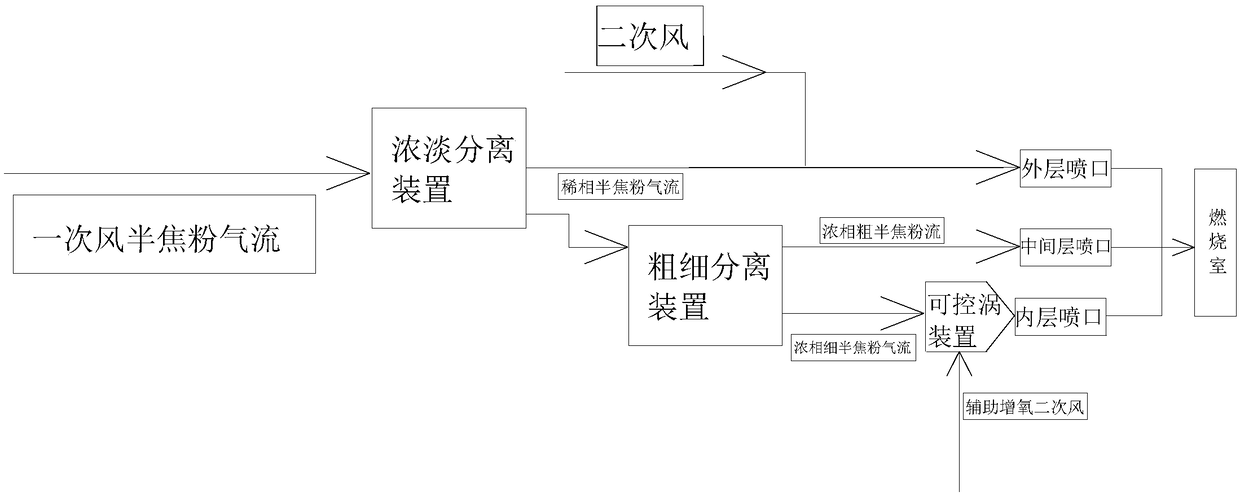

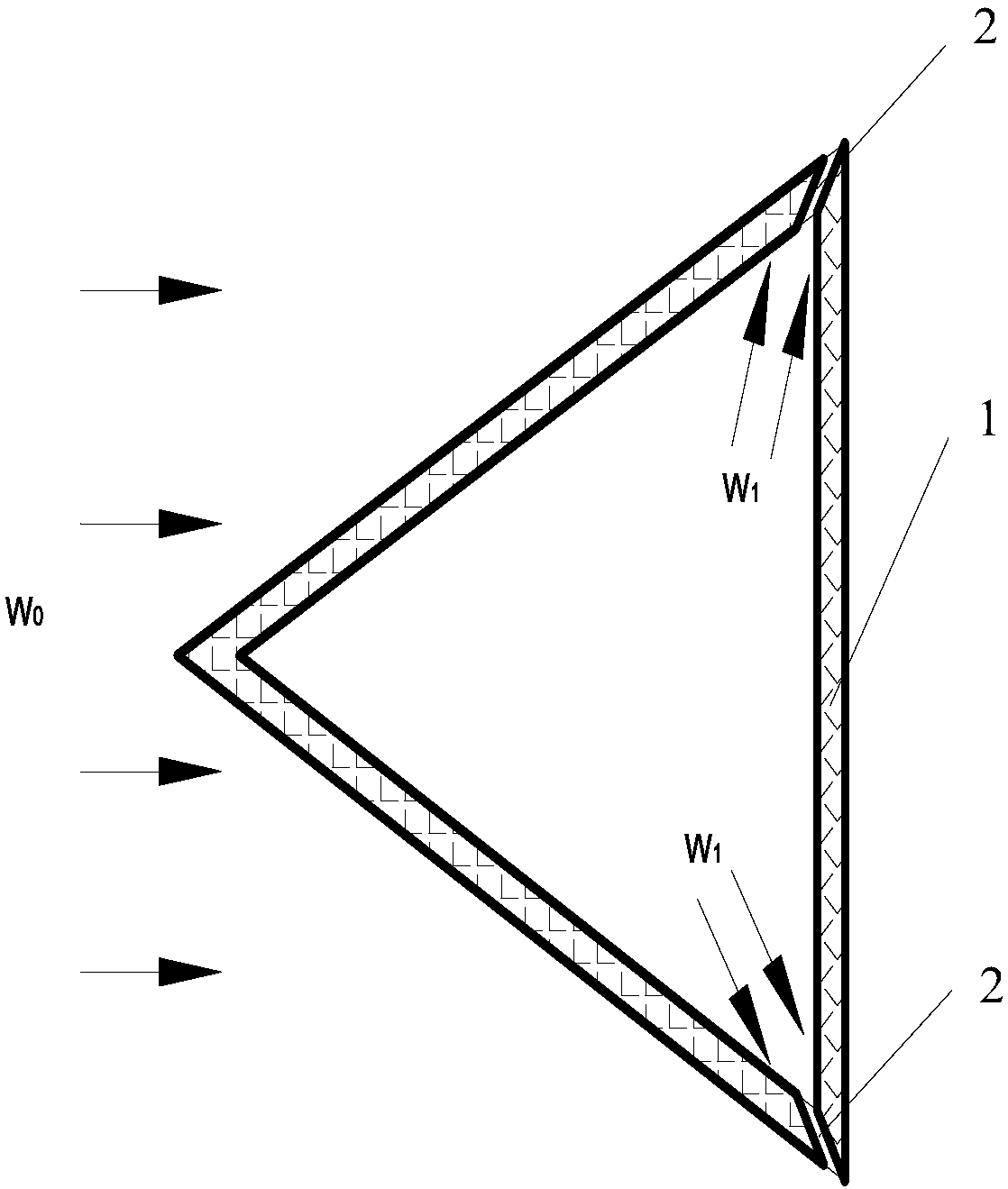

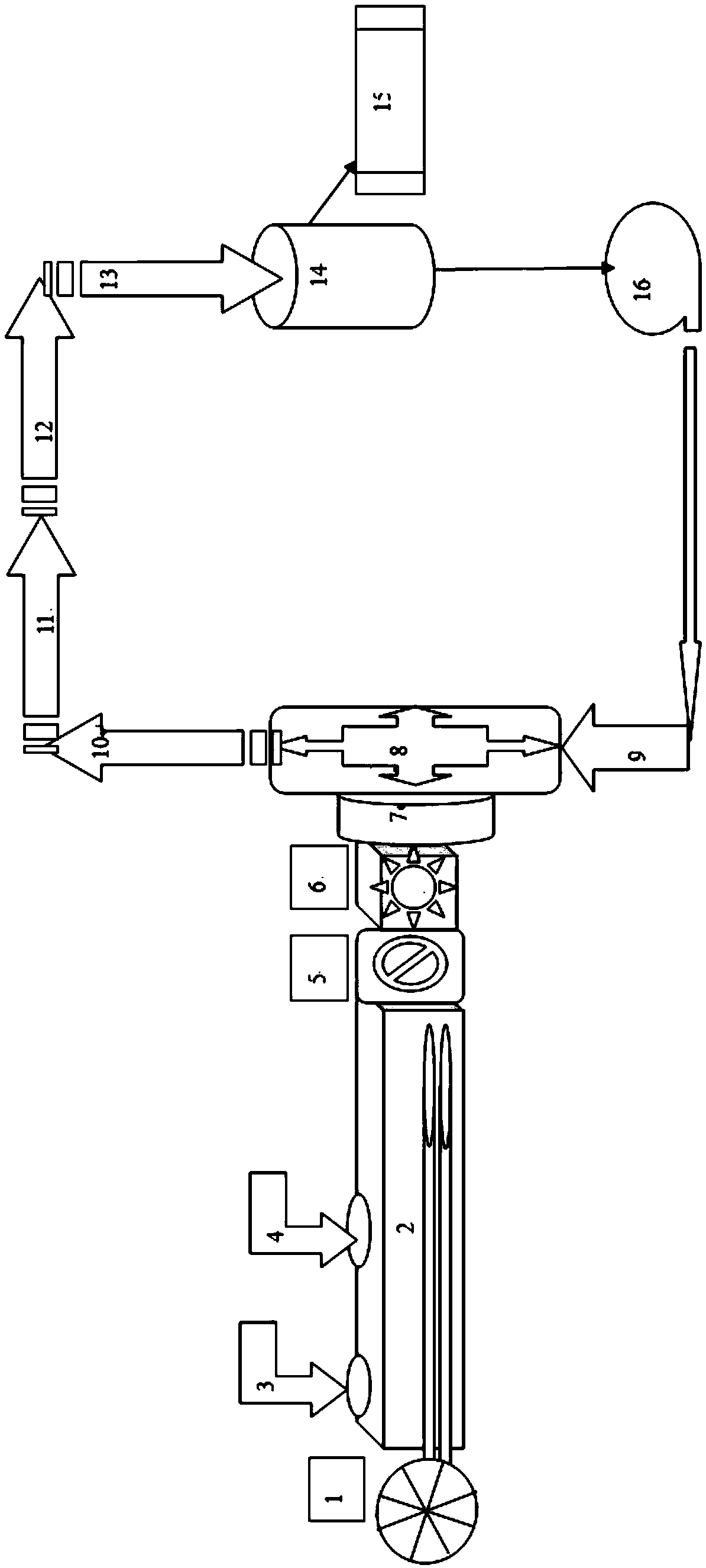

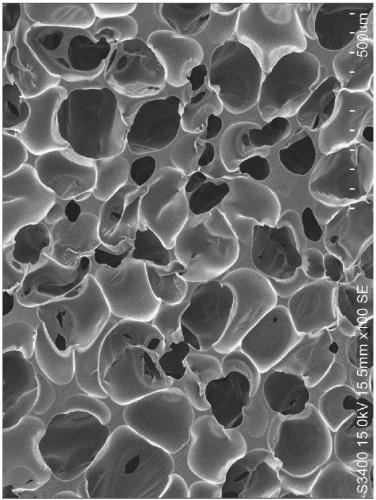

Method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies

InactiveCN106556007AFire stablePrevent high temperature corrosionFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberSlag

A method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies is characterized in that low-rank coal primary air semi-coke powder flow carrying gasified semi-coke is subjected to concentrated-dilute separation to obtain concentrated-phase semi-coke powder flow and dilute-phase semi-coke powder flow; the concentrated-phase semi-coke powder flow is subjected to coarse-fine separation to obtain concentrated-phase coarse semi-coke powder flow and concentrated-phase fine semi-coke flow; the dilute-phase semi-coke powder flow and secondary air are mixed, and the mixture is guided into an outer-layer nozzle of a combustion chamber; and the concentrated-phase fine semi-coke powder flow and the concentrated-phase coarse semi-coke powder flow are guided into an inner-layer nozzle and an intermediate-layer nozzle of the combustion chamber respectively and then sprayed into the combustion chamber, a controlled vortex bluff body device and an auxiliary aeration secondary air nozzle are mounted in the inner-layer nozzle of the combustion chamber, and during ignition, the concentrated-phase fine semi-coke powder flow sprayed by the inner-layer nozzle of the combustion chamber is ignited at first. The method can effectively improve ignition, combustion and burn-out characteristics of gasified semi-coke, reduces pollutant discharge and can effectively prevent a furnace wall from slag-bonding and a water wall from high-temperature corrosion.

Owner:CHONGQING UNIV

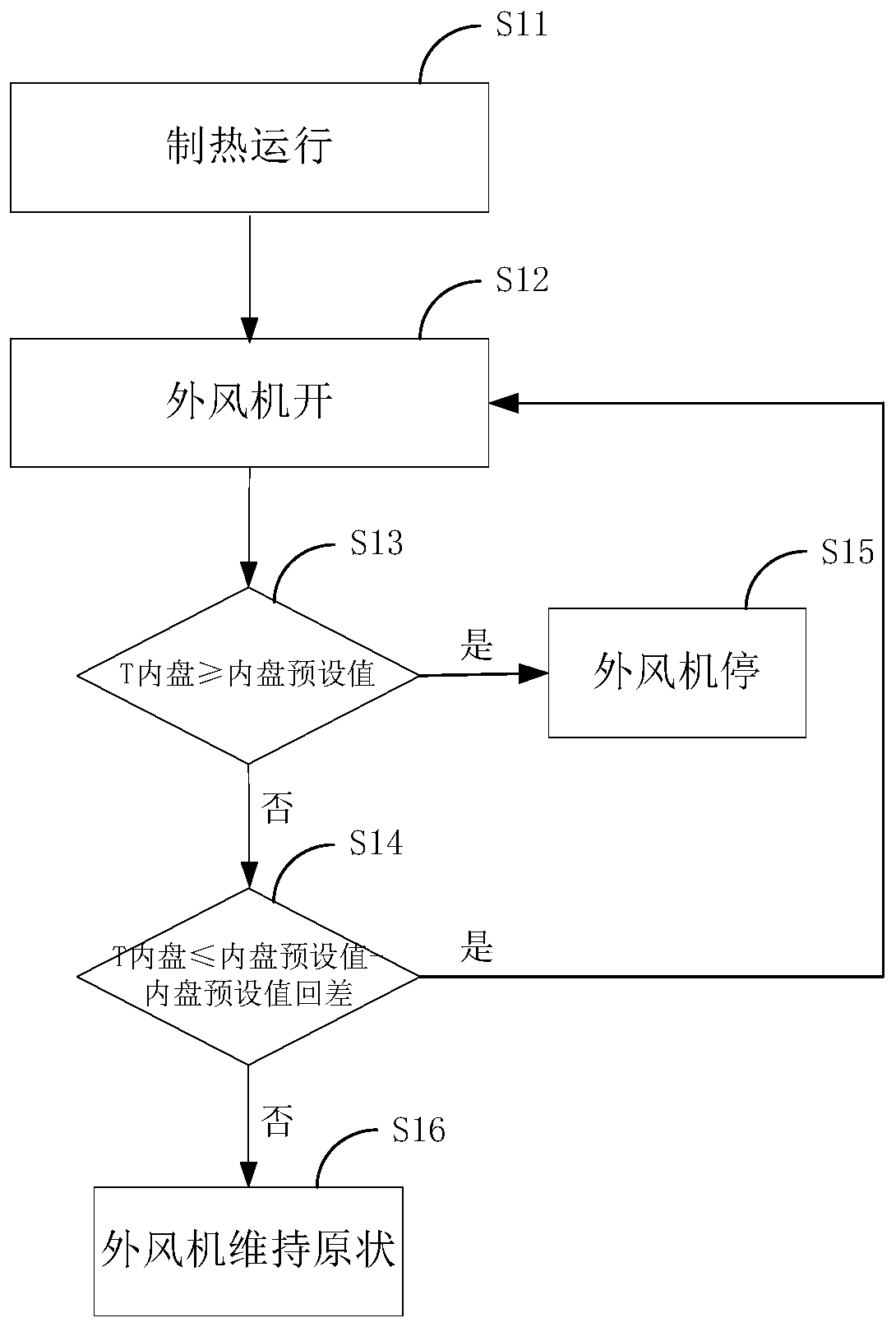

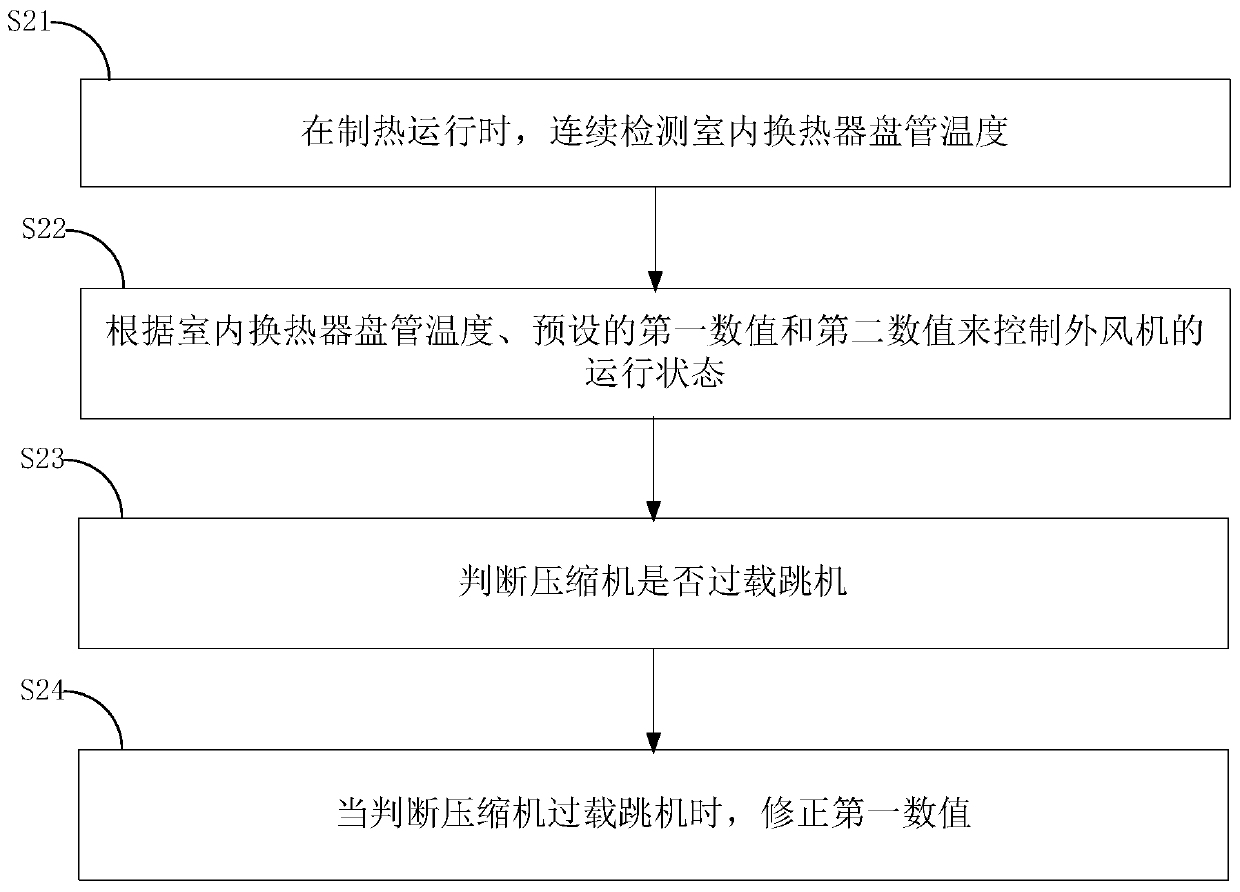

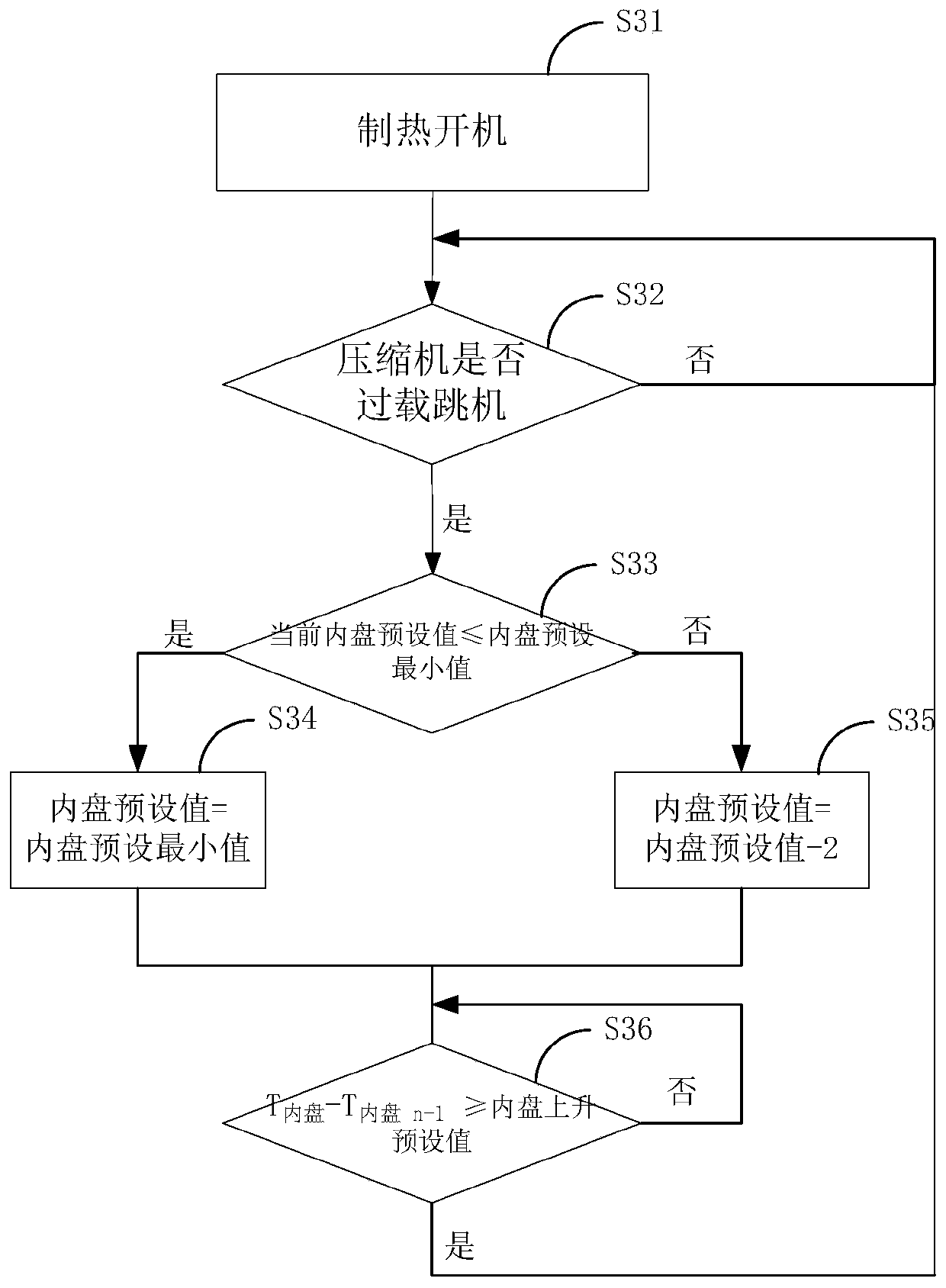

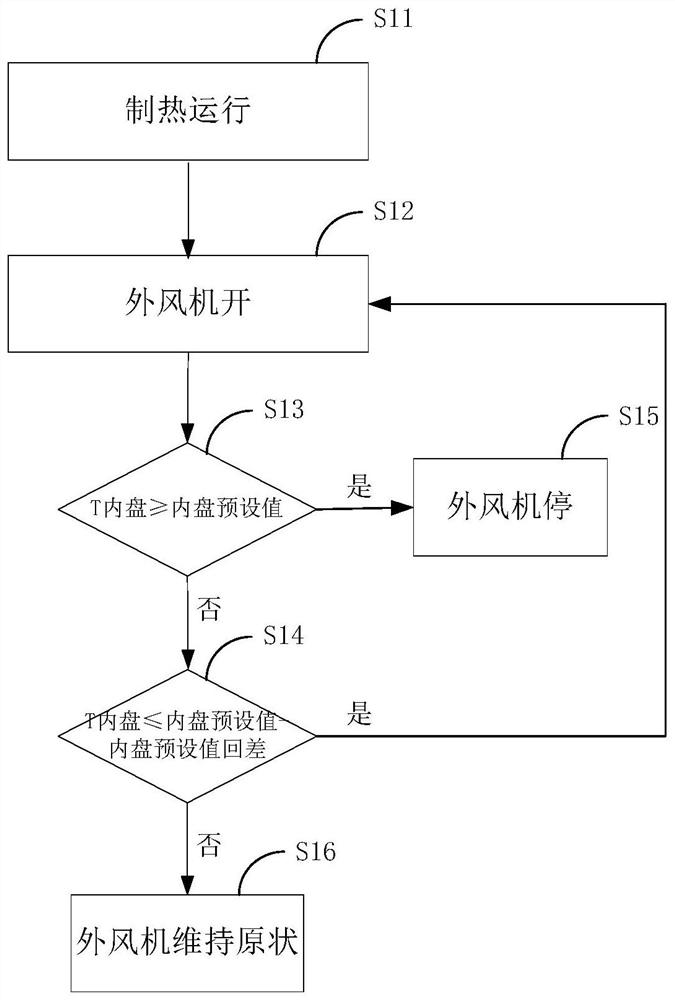

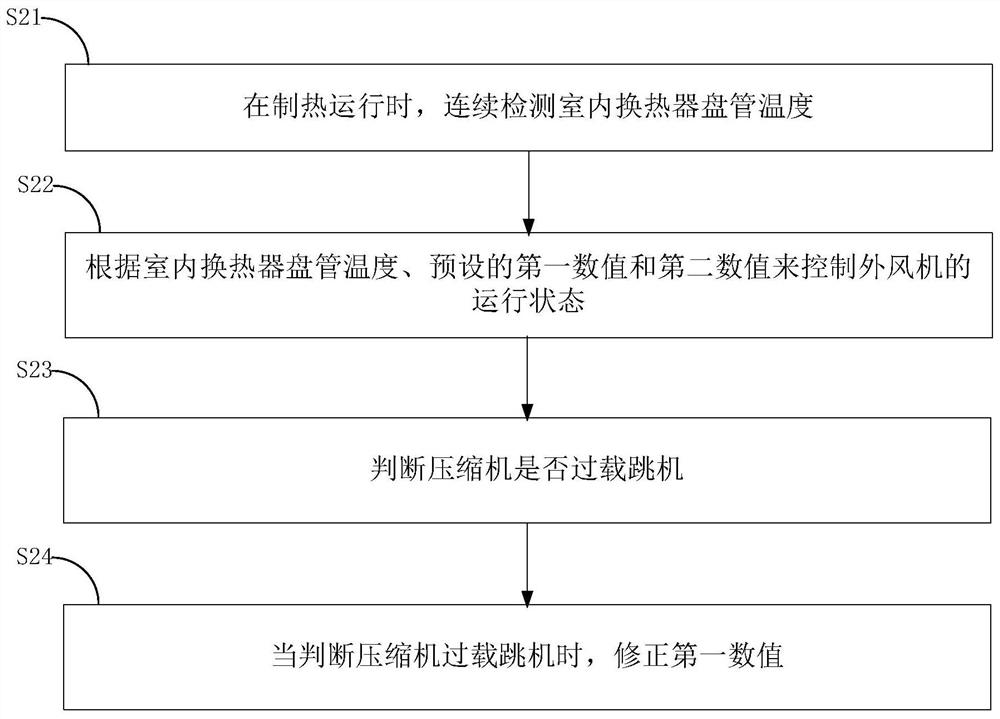

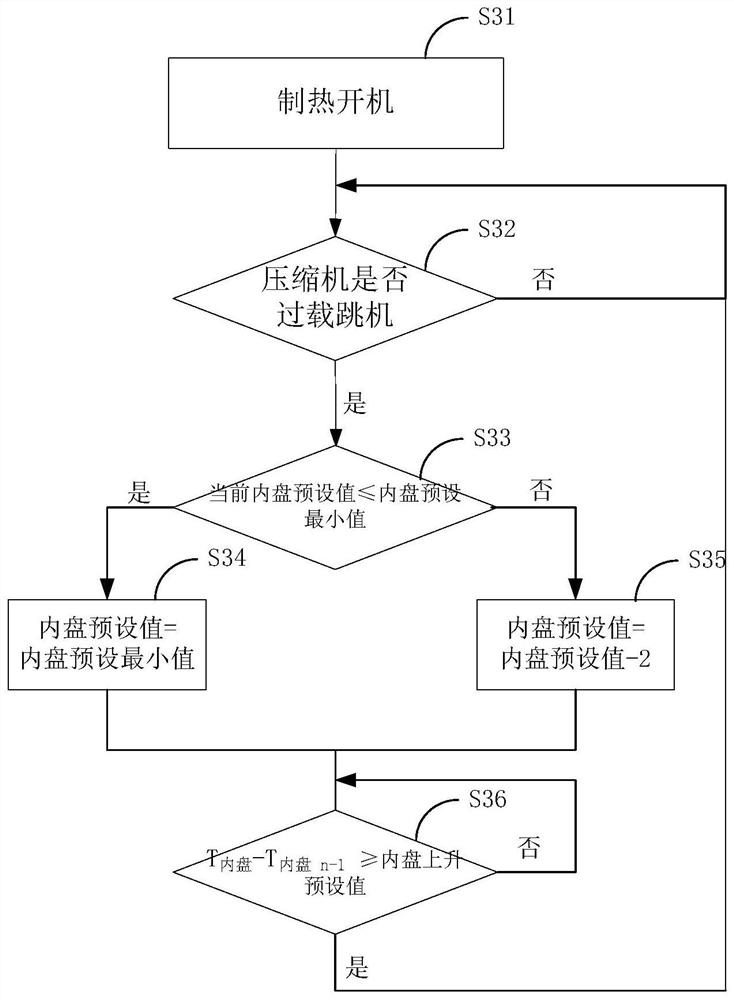

Heating anti-overload control method and device of air conditioner and air conditioner

ActiveCN110332649AGuaranteed timelinessAvoid rising costsMechanical apparatusSpace heating and ventilation safety systemsEngineeringOverload control

The invention provides a heating anti-overload control method and device of an air conditioner and the air conditioner, and relates to the technical field of air conditioners. The method comprises thesteps of: continuously detecting the temperature of an indoor heat exchanger coiler during heating; controlling an operation state of an outer fan according to the temperature of the indoor heat exchanger coiler, a preset first numerical value and a preset second numerical value; judging if a compressor is overloaded for tripping; and correcting the first numerical value when judging that the compressor is overloaded for tripping. The method judges if an air conditioning system is located in a high-load state through detection if the compressor is overloaded, so that a parameter set value oftriggering the outer fan to stop operation is corrected, the start and top protection timeliness and effectiveness of the outer fan are guaranteed, the frequent overload tripping of the compressor isprevented, and the heating anti-overload control of the air conditioner is realized.

Owner:NINGBO AUX ELECTRIC +1

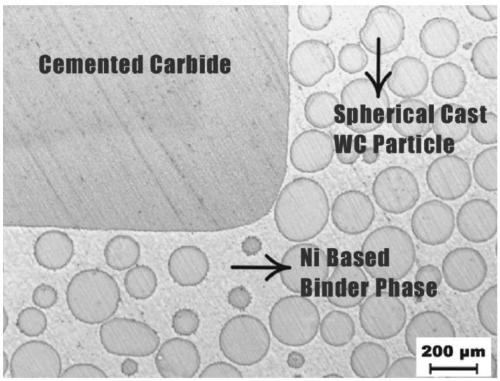

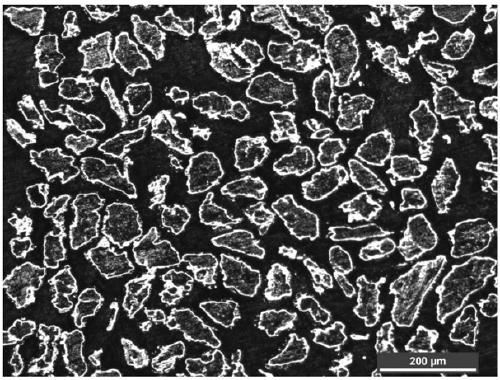

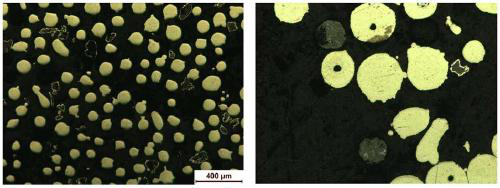

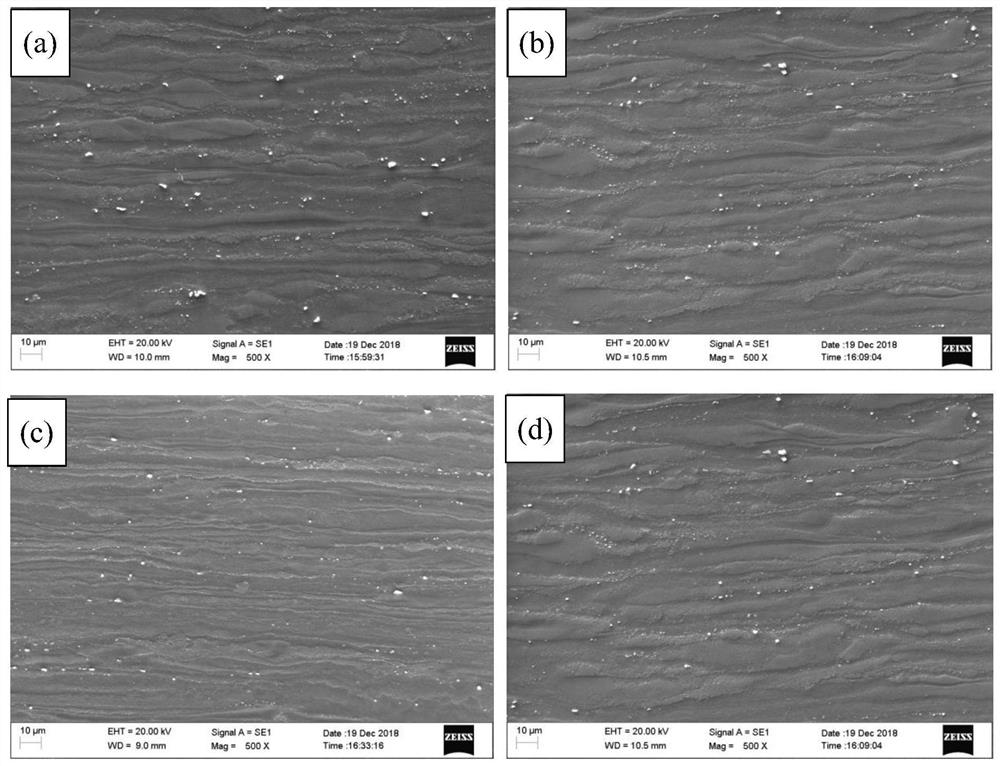

Tungsten carbide hard face abrasion-resistant bearing and preparation method thereof

InactiveCN109465461AChange the coefficient of surface frictionControl and Improve Friction and WearTransportation and packagingMetal-working apparatusAlloyCemented carbide

The invention provides a tungsten carbide hard face abrasion-resistant bearing. The tungsten carbide hard face abrasion-resistant bearing is composed of a hard alloy and a coating distributed on the periphery of the hard alloy; the coating is prepared from the following components, by volume percentage, 20%-55% of pure nickel or a nickel-based alloy, 2.5%-15% of a self-lubricating component, and 30%-77.5% of tungsten carbide particles; and the self-lubricating component is a nickel-coated molybdenum disulfide composite material or a nickel-coated graphite composite material. The invention further provides a preparation method of the tungsten carbide hard face abrasion-resistant bearing. According to the provided tungsten carbide hard face abrasion-resistant bearing, due to the existence ofthe lubricating component (such as graphite) in the coating, the friction coefficient of the surface of the hard face is lowered, and the abrasion performance can be effectively improved; and the lubricating component such as graphite is in three-dimensional uniform distribution, and can uninterruptedly occur on the new formed surface under the condition of initial surface abrasion, and thereforea self-lubricating effect is achieved.

Owner:SEED TECH CORP LTD

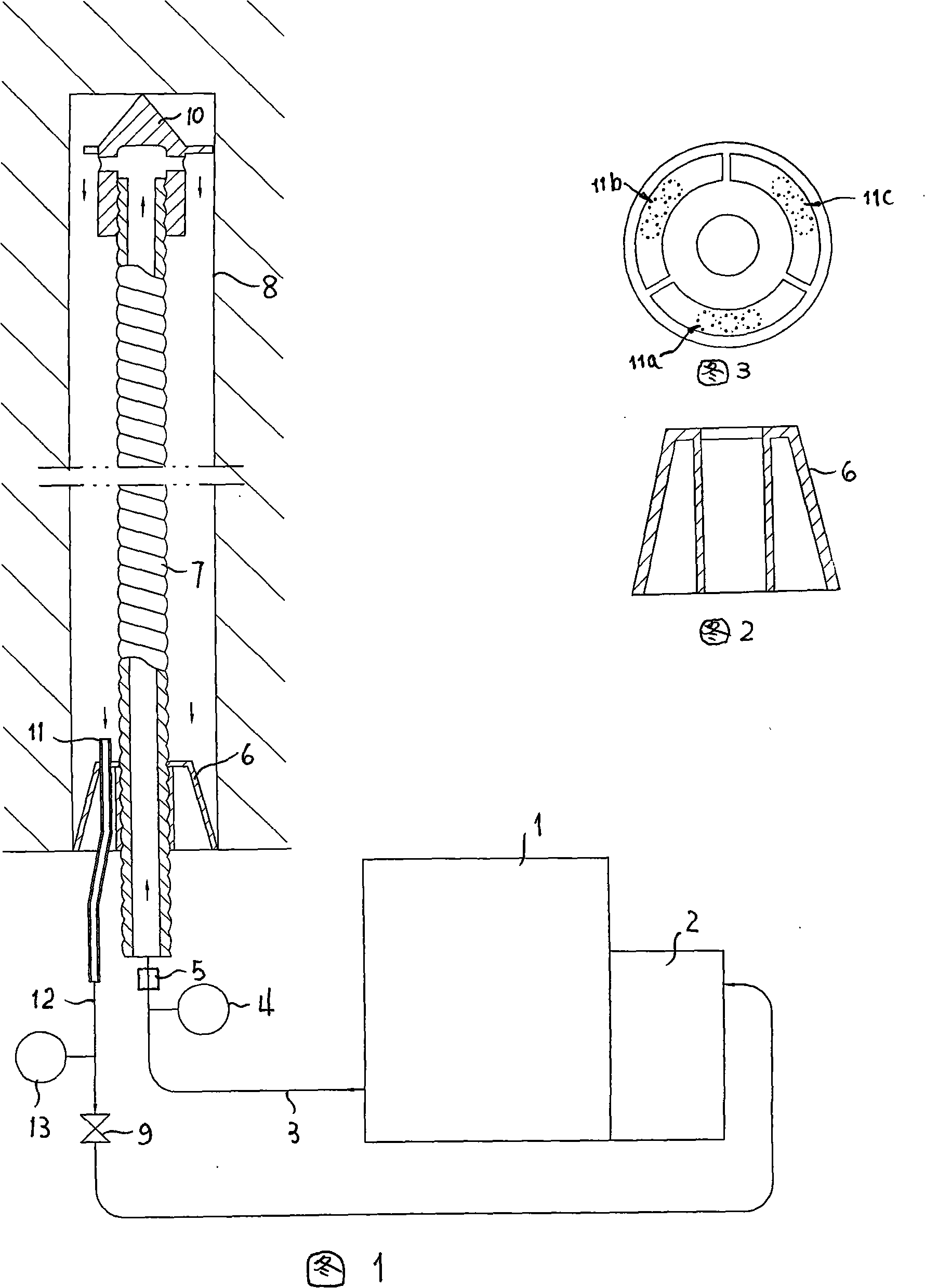

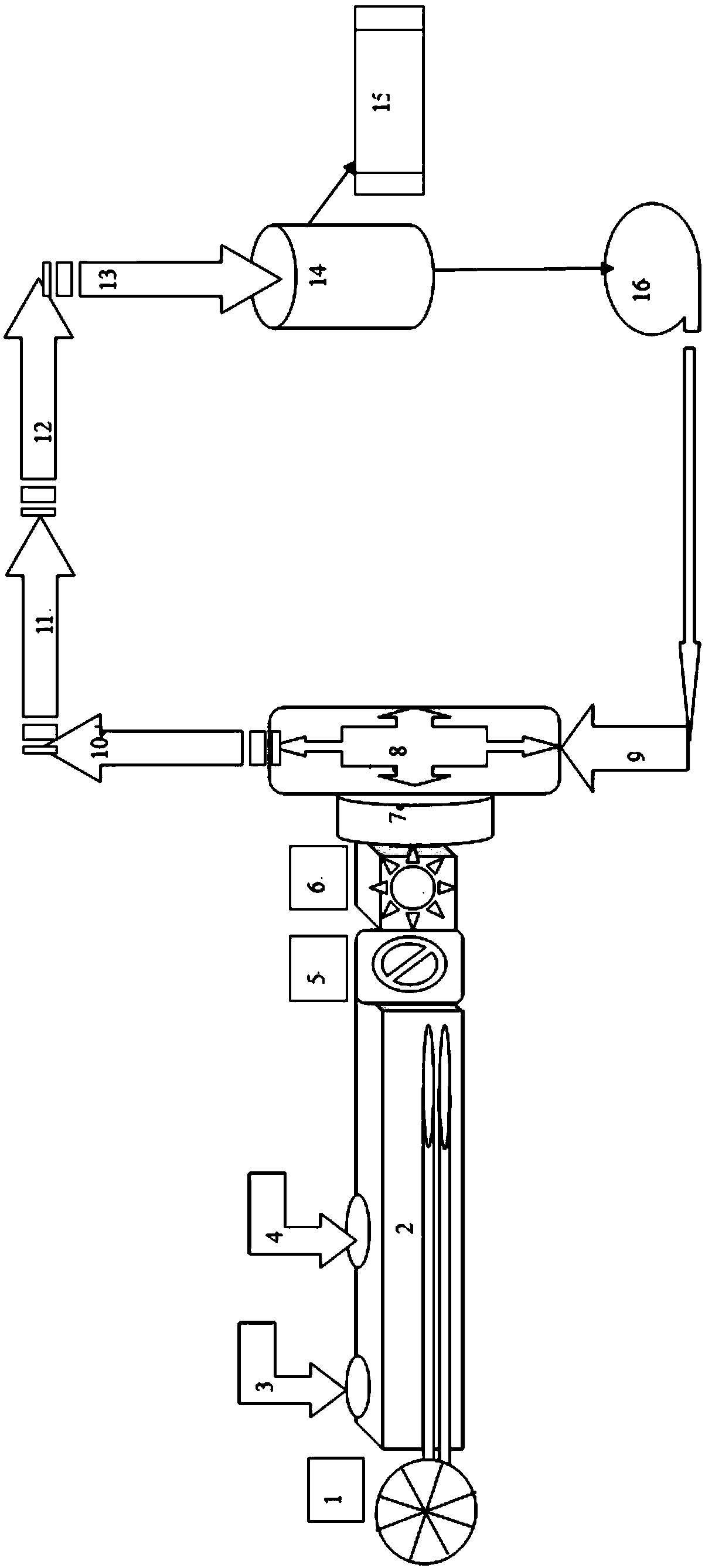

Hollow anchor stock circulating pressure slip casting construction method and special slip casting system thereof

InactiveCN101492917AEasily determine whether the filling is fullImproving the quality of anchoring engineeringAnchoring boltsBulkheads/pilesPulp and paper industryEngineering

The invention provides a hollow roof bolt circulating pressure slip casting method and a special slip casting system. The system comprises a hollow roof bolt, a pulp stop plug, a slip casting joint, a pulp outlet pipeline, a pressure gauge, a slip casting machine and a pulp reservoir; one end of a pulp returning pipeline is connected with a pulp returning joint and the other end extends above the pulp reservoir; the other end of the pulp returning joint is inserted into a half-opening lancing on the pulp stop plug and extends into the anchor eye in which the hollow roof bolt is arranged; the pressure gauge and a disconnecting valve are arranged at the pulp returning pipeline. According to the designed slip casting pressure, circulating pressure slip casting is realized in the real sense, thereby greatly improving slip casting construction quality.

Owner:CHENGDU MODERN WANTONG ANCHOR TECH

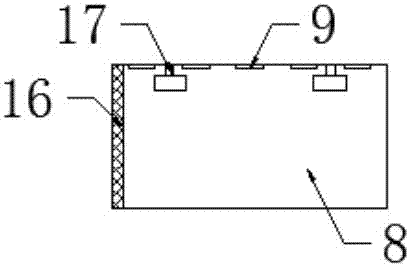

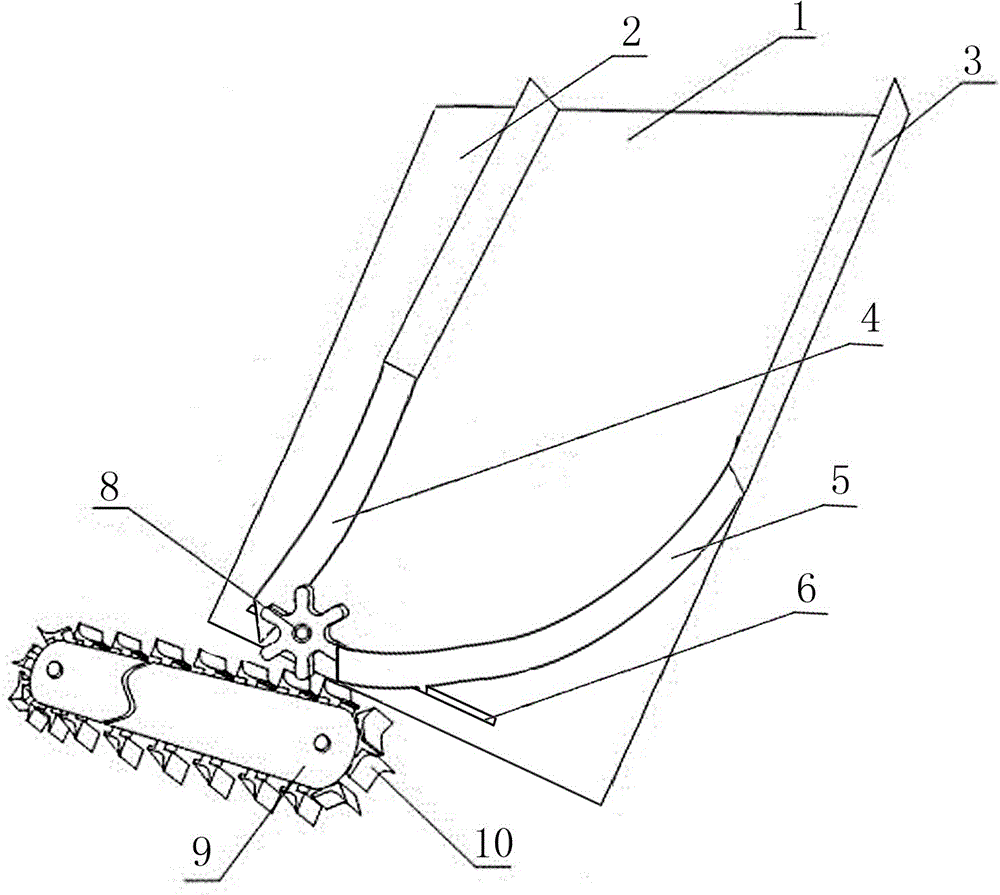

Water-cooled drilling machine slurry collecting device

InactiveCN107511937AStable absorptionImprove collection efficiencyWorking accessoriesStone-like material working toolsPulp and paper industrySlurry

The invention discloses a water-cooled drilling machine mud collecting device, comprising a device body, the device body is composed of a mud suction device arranged on the side of the device body, a telescopic conduit arranged on the side of the suction device, and an end portion of the telescopic conduit. This kind of water-cooled drilling machine mud collection device can effectively adjust the size of the mud suction by using the free opening and closing of the movable arc plate, and then fix the two movable arc plates to a suitable Therefore, it is suitable for drill bits of different sizes and is easy to use. At the same time, the suction cup can effectively fix the suction cup and keep the suction cup stable, so as to absorb the mud stably, avoid leakage, and greatly improve the collection efficiency of the mud. It can effectively heat and dry the mud and remove the moisture in the mud, so as to facilitate subsequent treatment, and it is very practical.

Owner:卢易达

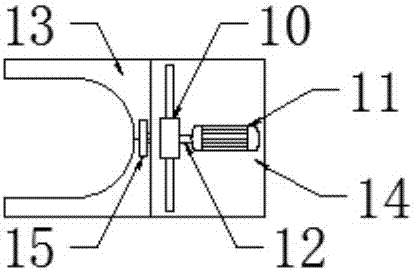

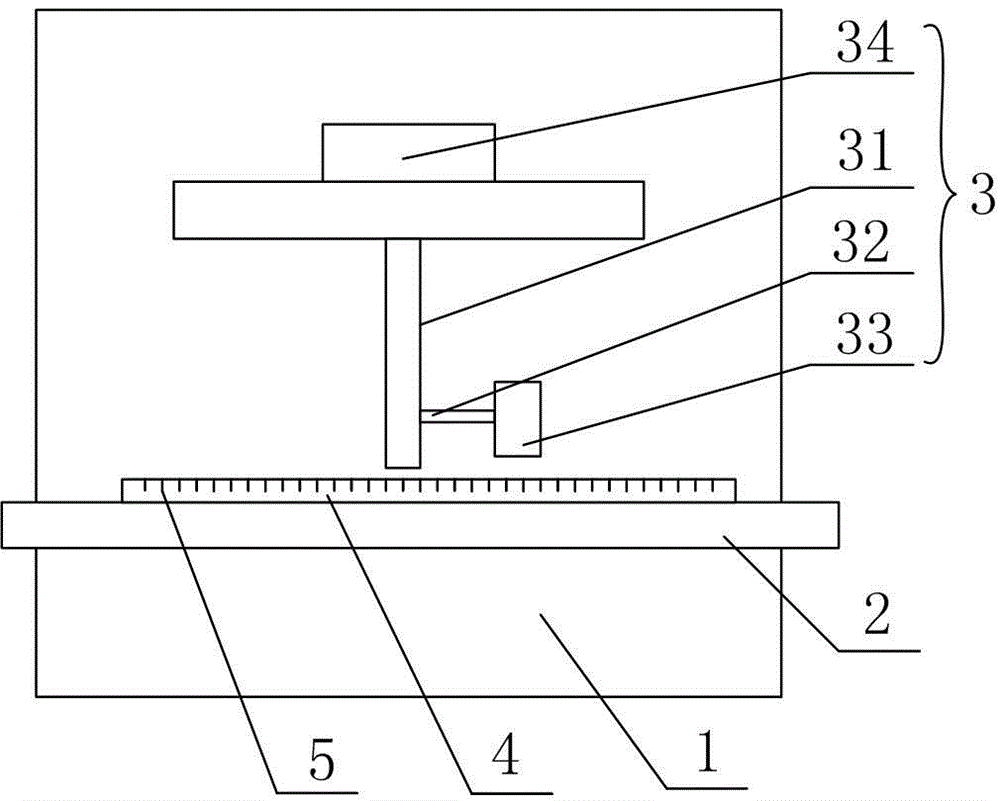

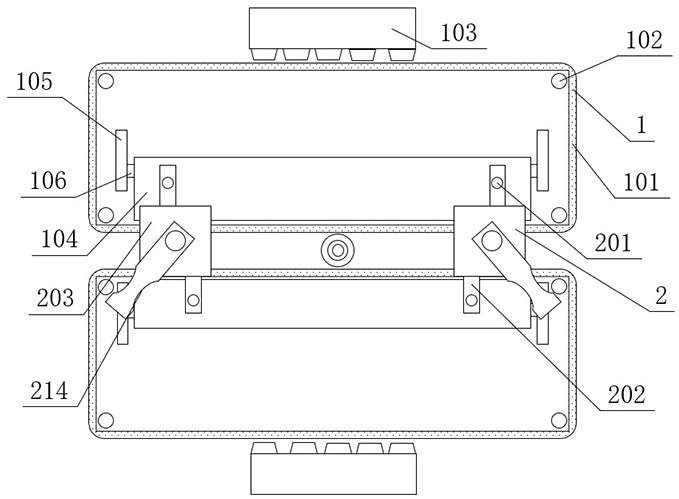

Machining device suitable for cutting round stainless steel sheet

InactiveCN105252126ASolve the problem of manually cutting stainless steel plates to obtain circular stainless steel platesEffective resizingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringScrew thread

The invention discloses a machining device suitable for cutting a round stainless steel sheet. The machining device comprises a cutting machine installing rack, a sheet fixing platform and a plasma cutting mechanism, wherein the sheet fixing platform and the plasma cutting mechanism are arranged on the cutting machine installing rack. The machining device is characterized in that the plasma cutting mechanism comprises a rotary rod with the top end connected to the cutting machine installing rack, and a plasma cutting head fixed to the bottom end of the rotary rod through a transversely-stretching rod; the transversely-stretching rod comprises an inner rod with an external thread and two outer rods; and one end of one outer rod is in threaded connection with the inner rod, the other end of one outer rod is fixedly connected with the bottom end of the rotary rod, one end of the other outer rod is in threaded connection with the inner rod, and the other end of the other outer rod is fixedly connected with the plasma cutting head. The machining device has the beneficial effects that operation is easy and convenient, and raw materials are saved.

Owner:CHENGDU XINDU SANLI PLASTIC CO LTD

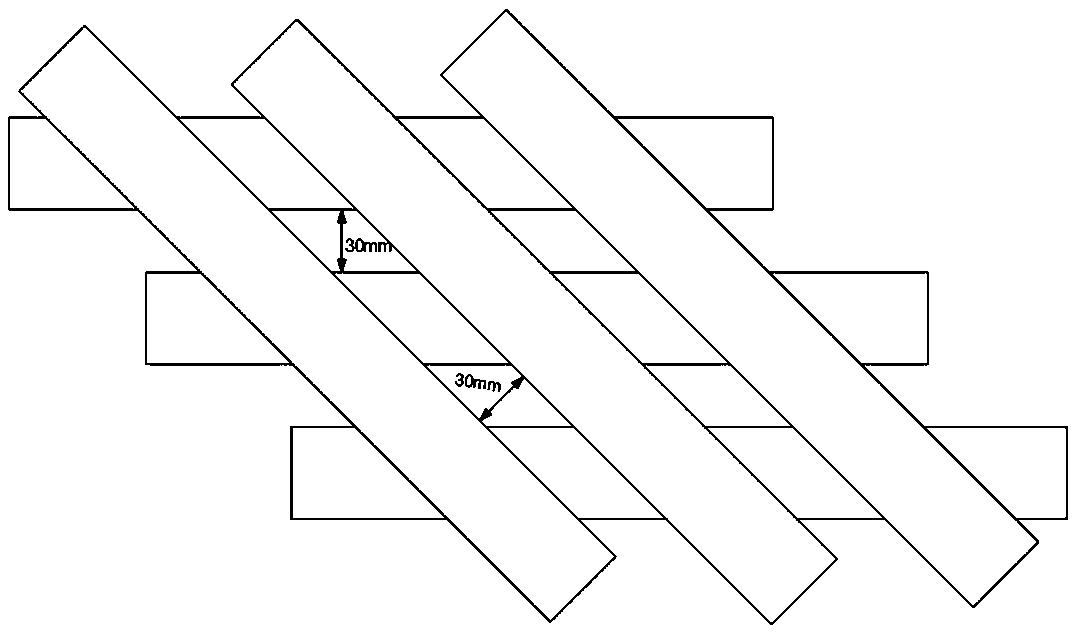

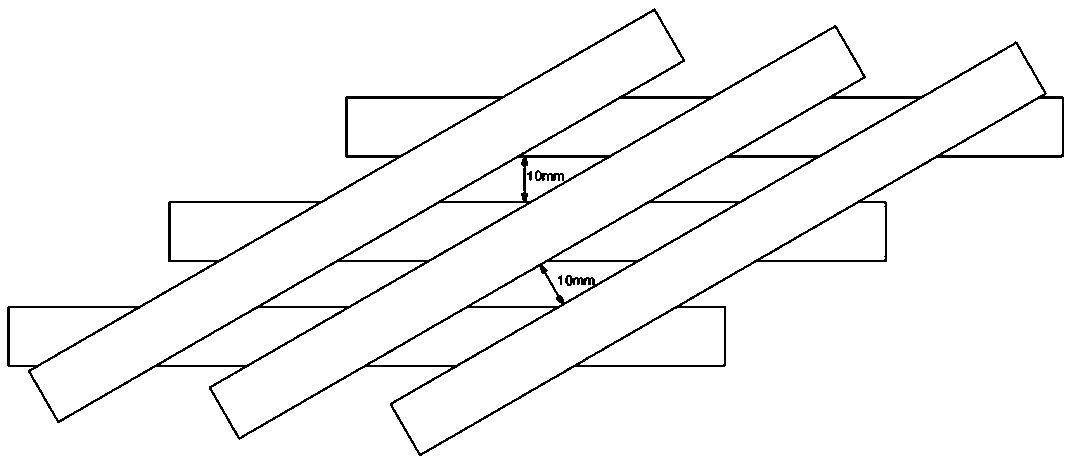

Antibacterial spunlace non-woven fabric and preparation method thereof

InactiveCN111286867AUniform and good filterabilityUniform and good air permeabilityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer scienceCarding

The invention belongs to the technical field of non-woven fabrics and discloses an antibacterial spunlace non-woven fabric and a preparation method thereof. The method comprises the following steps ofperforming opening; performing film covering: stirring and dissolving protein hydrogel to obtain a film coating solution, immersing the opened non-woven fabric monomer fibers into the film coating solution at least once, performing drying, and performing compounding on the surfaces of the non-woven fabric monomer fibers to form a hydrogel film layer with a specified thickness; performing cardingto form a net, wherein the fiber net at least comprises two layers of non-parallel fibers, and the carding of each layer of fibers is as follows: laying, in a flat way, a plurality of non-woven fabricmonomer fibers coated with the hydrogel film layer in parallel through ultrasonic vibration; and performing spunlace molding: placing the carded and molded fiber net on an injector, first carrying out spunlace treatment on the fiber net for 5-10 minutes with a sodium hydroxide solution having the pH value greater than 11.5 and the temperature from 30 DEG C to 85 DEG C, and then carrying out the spunlace treatment on the fiber net for 25-30 minutes with atomized water to prepare the porous antibacterial spunlace non-woven fabric, wherein the uniformity of the sizes of through holes in the non-woven fabric can be effectively ensured based on the steps.

Owner:GUANGZHOU SANTAI AUTOMOTIVE TRIM MATERIALS

A kind of preparation method of thermoplastic polyurethane micro-airbag elastomer material

ActiveCN107383854BReduce dicingReduce energy consumptionChemical/physical/physico-chemical stationary reactorsPolymer scienceThermoplastic polyurethane

The invention relates to a preparation method of a thermoplastic polyurethane micro-airbag elastomer material, which comprises the following steps: (1) feeding liquid raw materials such as diisocyanate molecules and solid additives into a twin-screw reactor to carry out polymerization chain extension reaction to obtain high molecular weight (2) Push the high molecular weight hot melt into the mixing extruder to continue the reaction to generate a high molecular thermoplastic polyurethane melt; (3) continue to combine the obtained high molecular thermoplastic polyurethane melt with the polymer Pellets, etc. are added to the foaming extruder, and then extruded from the die head to the underwater pelletizing chamber in the form of high-pressure hot melt; (4) The pellets are carried by the process water and sent to the separation process through the multi-stage pressure release and expansion process water pipeline. Machine place, after separation, screening and drying, the target product will be formed. Compared with the prior art, the present invention can directly produce thermoplastic polyurethane elastomer materials from liquid raw materials such as MDI, which greatly reduces energy consumption and material consumption, and improves product yield and production efficiency.

Owner:NANTONG DE NEW MATERIAL CO LTD

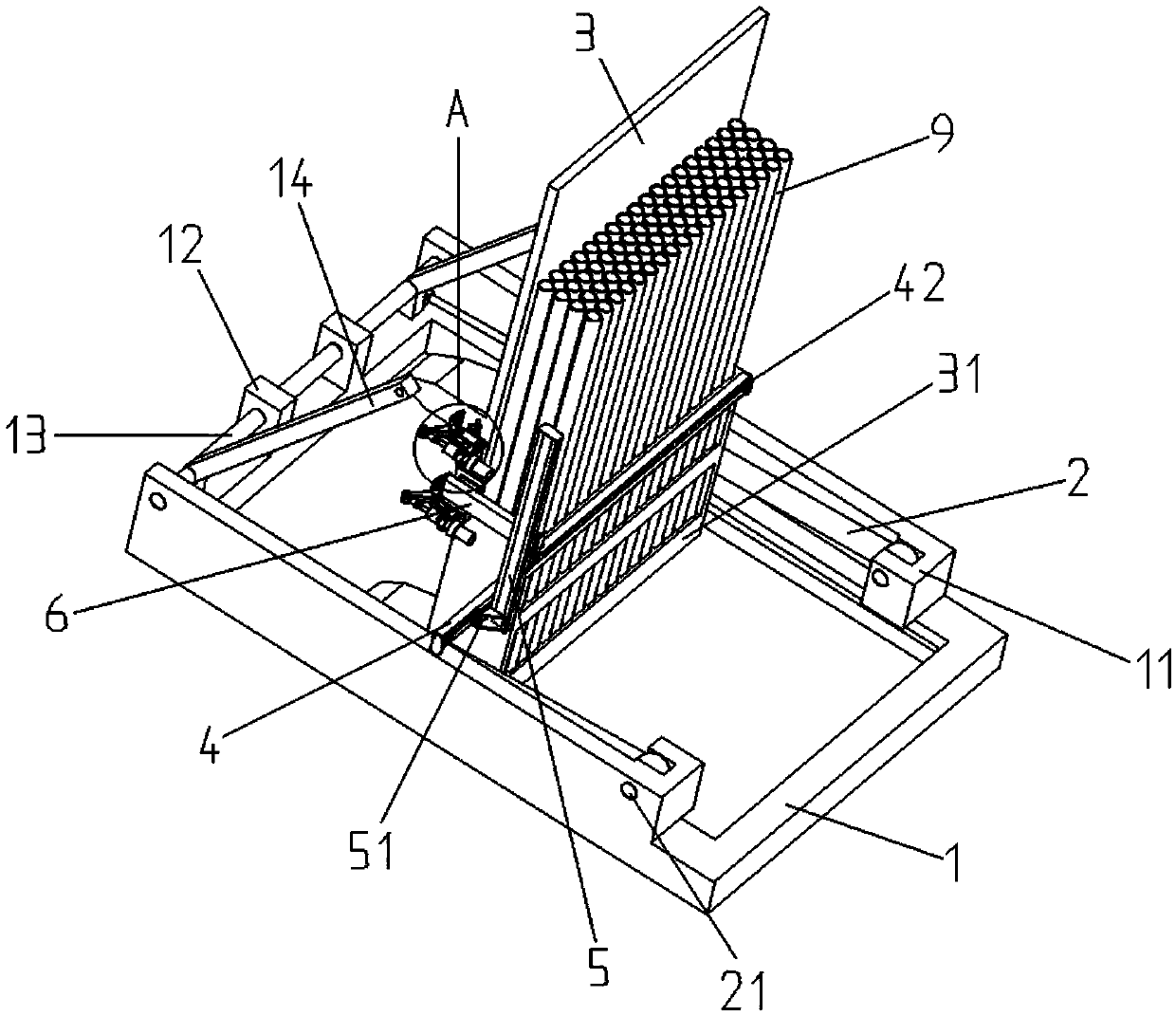

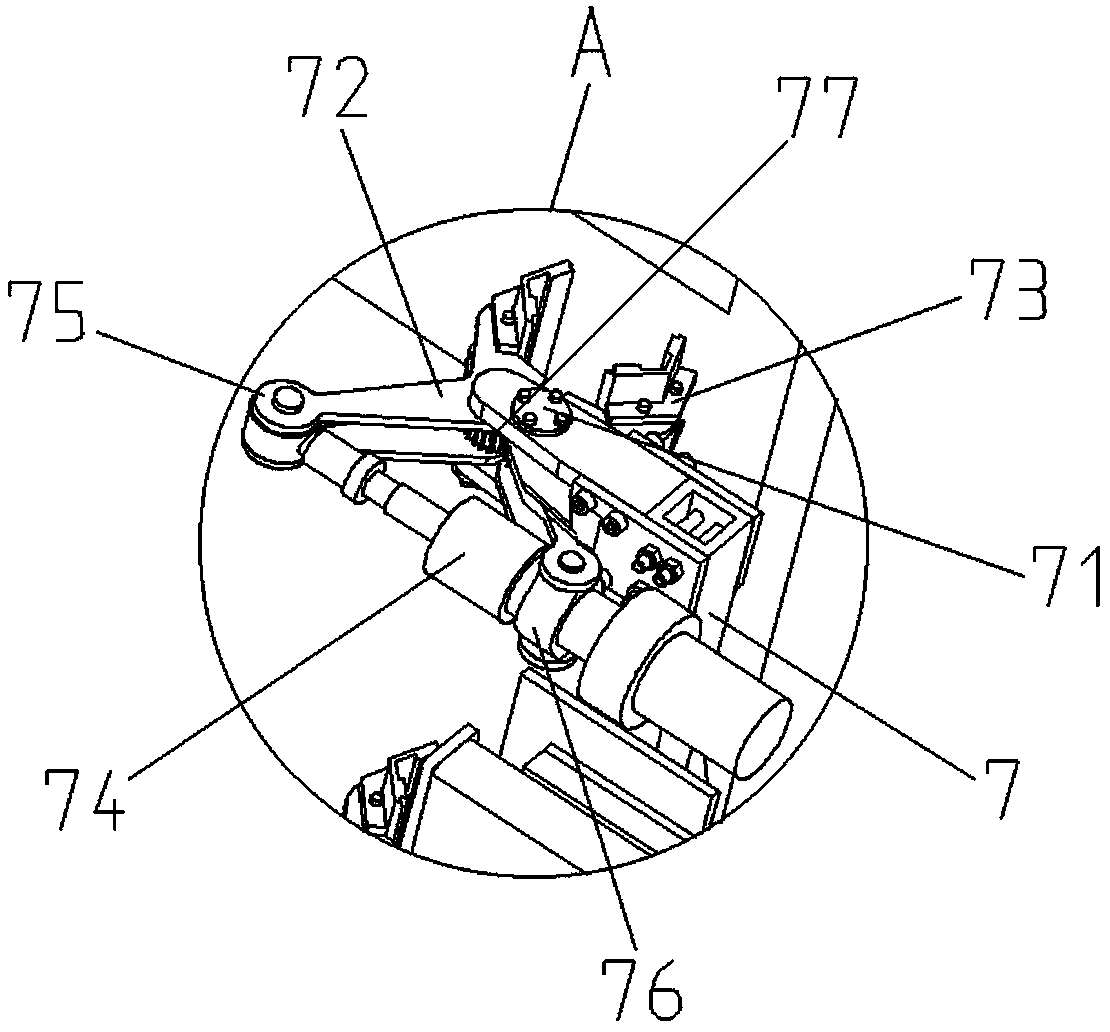

Automatic discharging, moving and swinging device of geological exploration drill pipe

InactiveCN109538138ASimple structureEasy to operateDrilling rodsDrilling casingsEngineeringGeological exploration

The invention discloses an automatic discharging, moving and swinging device of a geological exploration drill pipe, and belongs to the technical field of geological drilling. The device comprises a bottom frame body and a drill pipe vertical frame, one end of the bottom frame body is provided with a vertical driving hydraulic cylinder through a shaft, and the vertical driving hydraulic cylinder is connected with a supporting frame shaft arranged at the other end of the bottom frame body through a shaft; the bottom end of the rear portion of the drill pipe vertical frame is arranged in a sliding groove in the inner side of the bottom frame body through a shaft, and the supporting frame shaft is in shaft connection with the middle of the rear portion of the drill pipe vertical frame; a vertical limiting frame is arranged on the front side of the drill pipe vertical frame, a transverse sliding frame is arranged on the outer side of the vertical limiting frame, and a transverse driving module and a vertical sliding frame are arranged in the transverse sliding frame; a vertical driving module and a lateral sliding frame are arranged in the vertical sliding frame, a lateral driving module and a clamping mounting frame are arranged in the lateral sliding frame, and a clamping jaw is arranged on the clamping mounting frame. The problems that existing drill pipe discharging, moving andswinging equipment is tedious in step and low in flexibility are solved, drill pipes to be conveyed in batches can be vertically erected in advance, the drill pipes are clamped by clamping bodies oneby one, and the overall stability is improved.

Owner:陈小龙

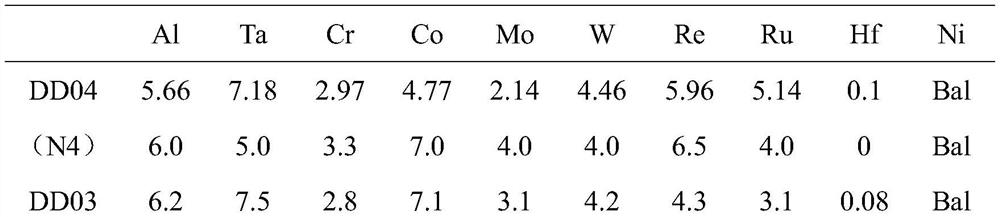

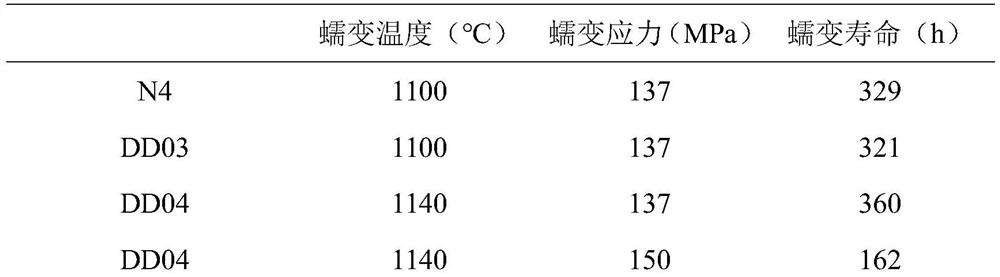

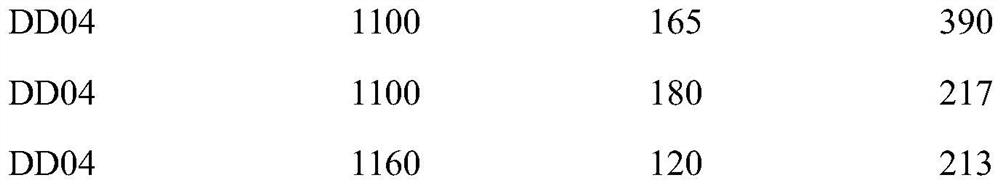

High-concentration Re/Ru nickel-based single crystal superalloy with high temperature bearing capacity and high creep resistance

InactiveCN112522543ADistribution ratio is goodImprove thermal stabilityPolycrystalline material growthAfter-treatment detailsRheniumHigh concentration

The invention relates to a high-concentration Re / Ru nickel-based single crystal superalloy with high temperature bearing capacity and high creep resistance, and belongs to a new material for special purposes. The nickel-based superalloy comprises the following components of, in percentage by mass, 5.4-6.2% of aluminum, 7.2-7.8% of tantalum, 2.6-3.5% of chromium, 1.7-2.5% of molybdenum, 4.2-4.8% ofcobalt, 4.2-5.0% of tungsten, 5.8-6.4% of rhenium, 4.7-5.4% ruthenium, 0.07-0.12% of hafnium and the balance nickel. The preparation method of the nickel-based superalloy comprises a heat treatment process. The single-crystal nickel-based alloy has high temperature bearing capacity, good high-temperature mechanical property and creep property, good creep strength and long service life under the ultrahigh-temperature condition, and is a nickel-based single-crystal superalloy suitable for producing blades of hot end parts of high-thrust-ratio aero-engines and gas turbines.

Owner:GUIZHOU UNIV OF ENG SCI

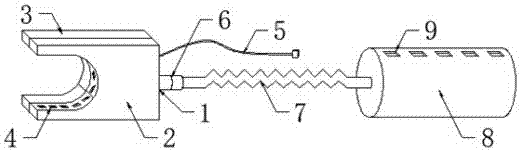

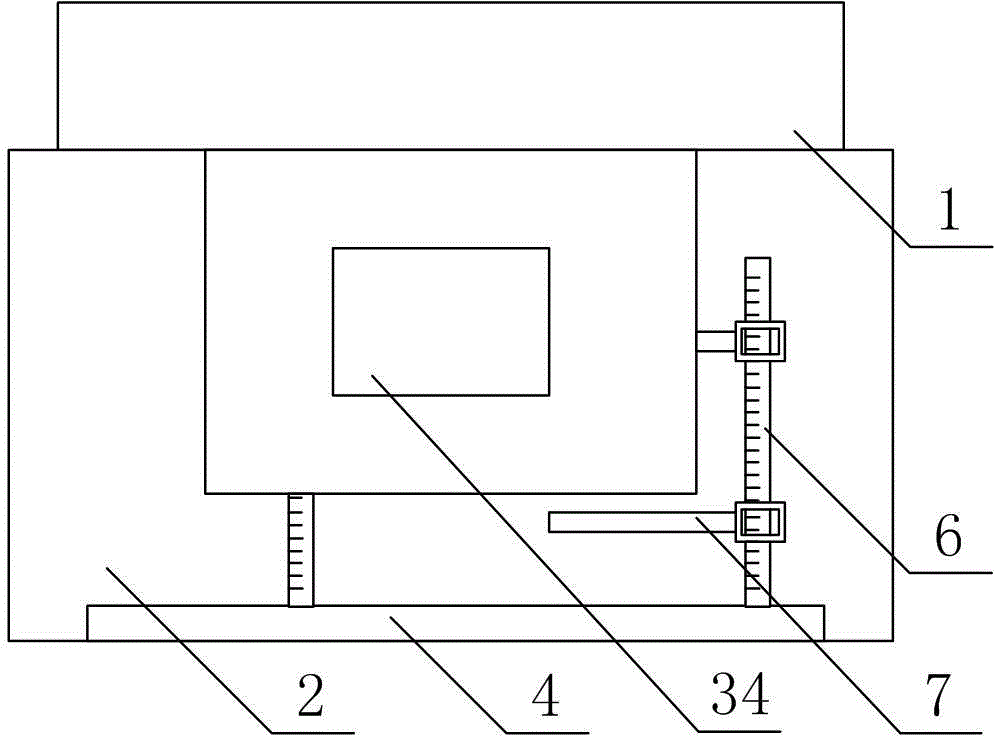

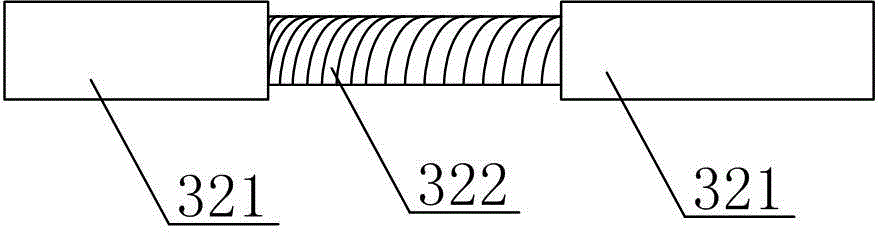

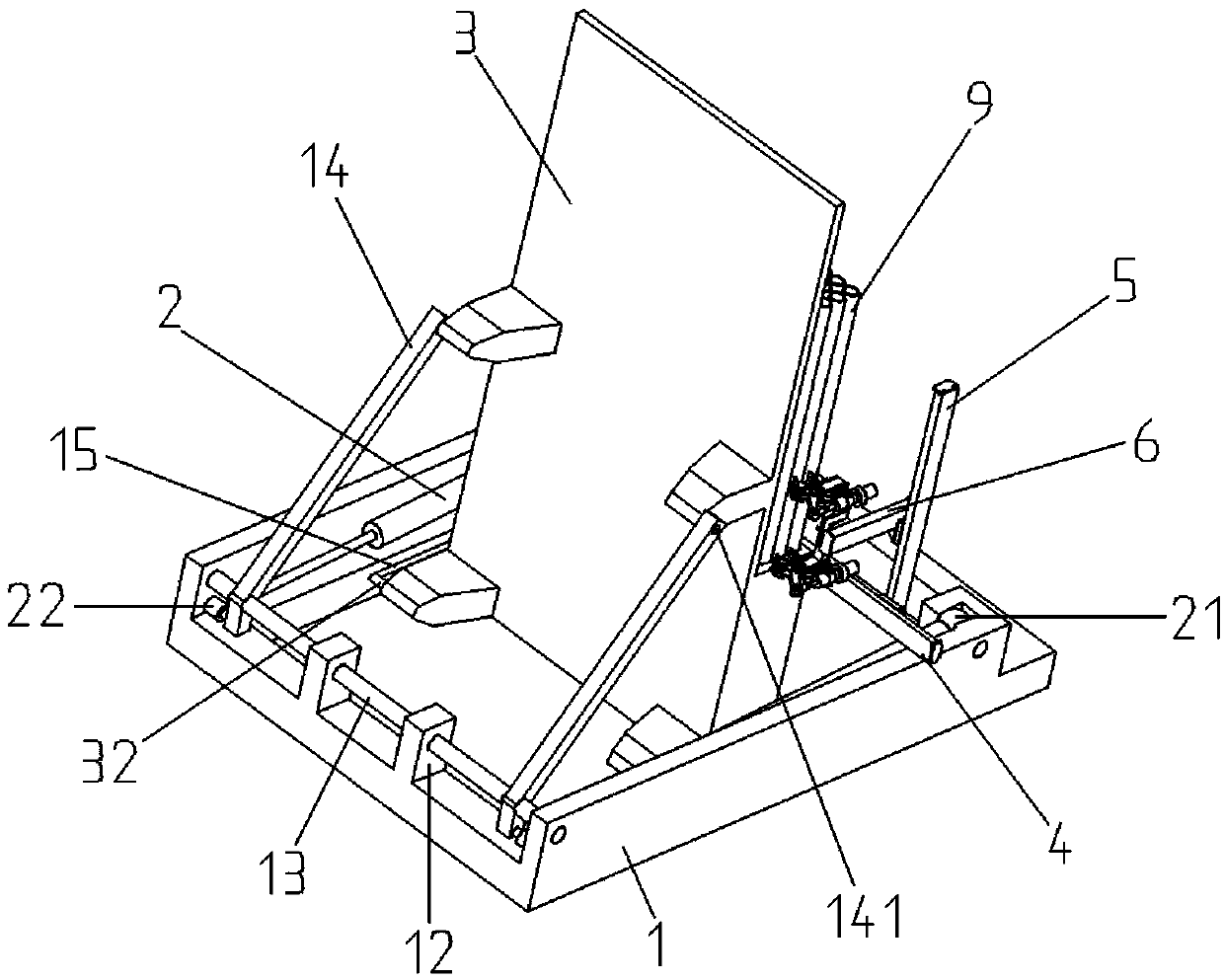

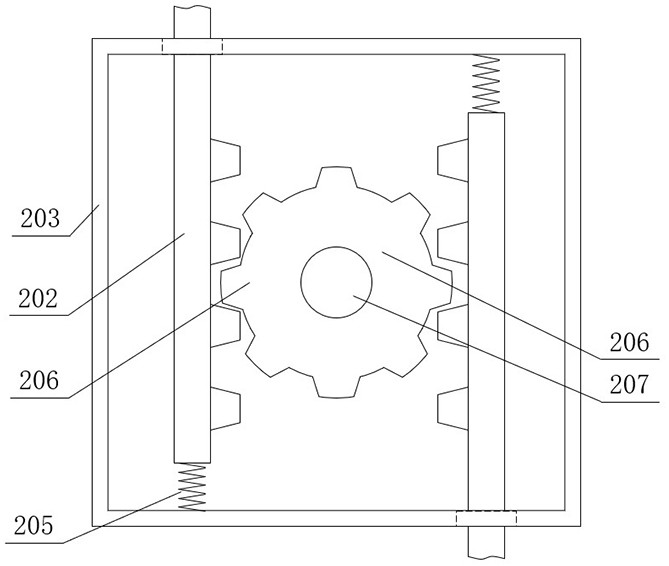

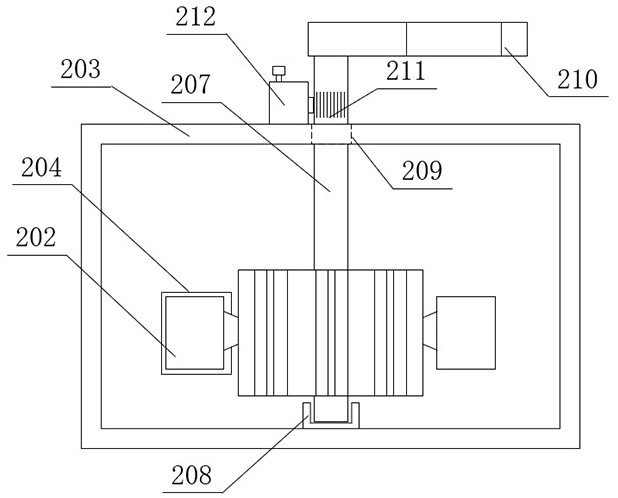

A felt painting device and enameled wire

ActiveCN112934582BGood paint effectEffective spacing adjustmentLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:ZHEJIANG TONY ELECTRONICS CO LTD

A heating and anti-overload control method and device for an air conditioner and an air conditioner

ActiveCN110332649BGuaranteed timelinessGuaranteed validityMechanical apparatusSpace heating and ventilation safety systemsAir conditioningHeat exchanger

The invention provides a heating anti-overload control method and device of an air conditioner and the air conditioner, and relates to the technical field of air conditioners. The method comprises thesteps of: continuously detecting the temperature of an indoor heat exchanger coiler during heating; controlling an operation state of an outer fan according to the temperature of the indoor heat exchanger coiler, a preset first numerical value and a preset second numerical value; judging if a compressor is overloaded for tripping; and correcting the first numerical value when judging that the compressor is overloaded for tripping. The method judges if an air conditioning system is located in a high-load state through detection if the compressor is overloaded, so that a parameter set value oftriggering the outer fan to stop operation is corrected, the start and top protection timeliness and effectiveness of the outer fan are guaranteed, the frequent overload tripping of the compressor isprevented, and the heating anti-overload control of the air conditioner is realized.

Owner:NINGBO AUX ELECTRIC +1

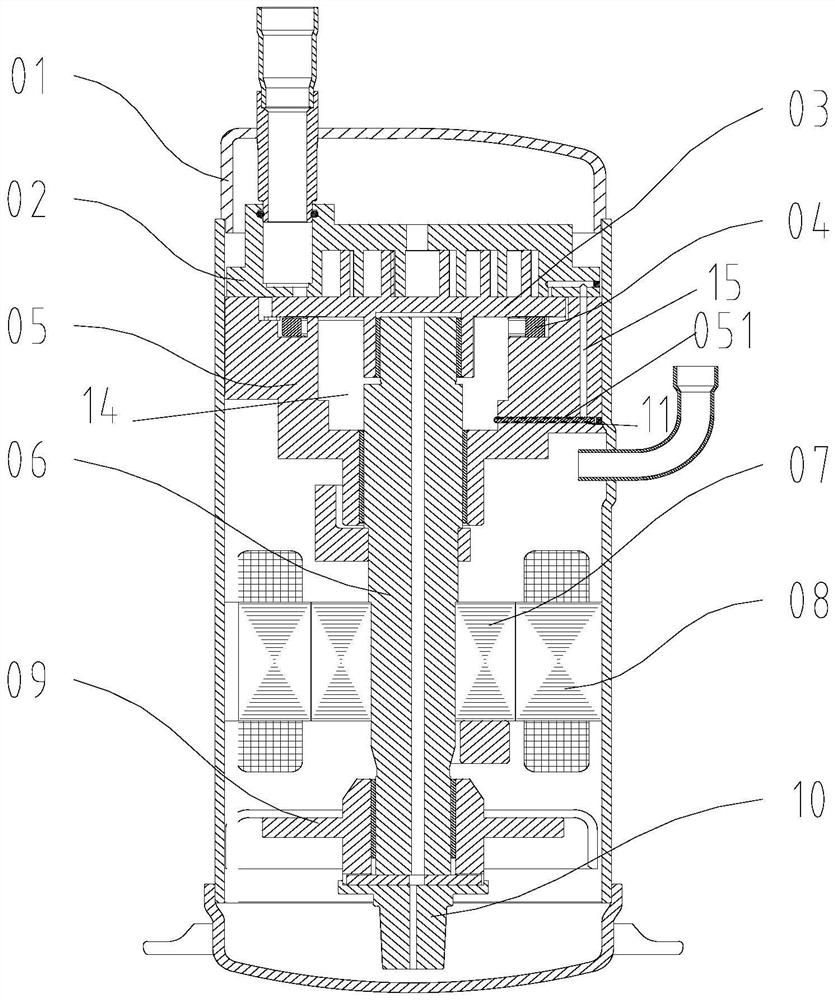

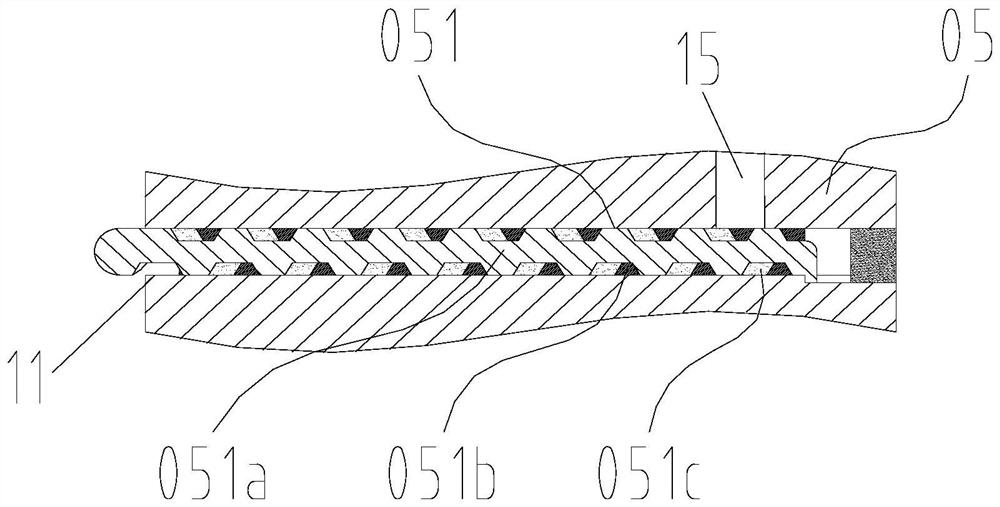

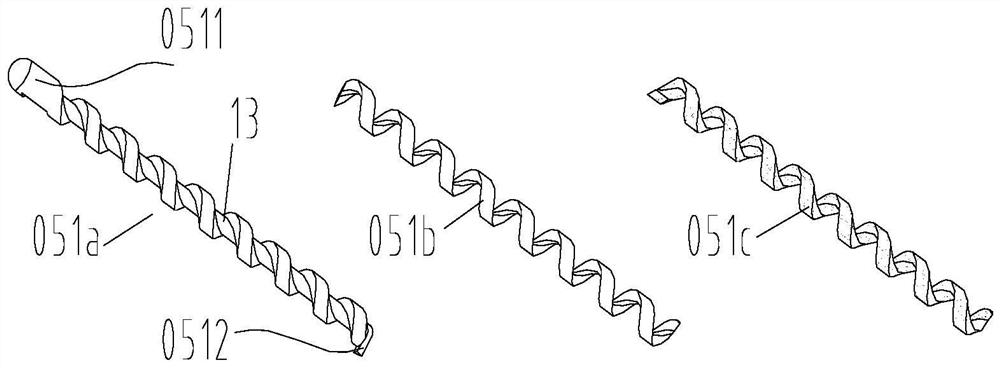

Oil path throttling device of compressor, compressor and air conditioner

PendingCN114412782AAvoid compromising energy efficiencyAvoid excessive back pressureRotary piston pumpsRotary piston liquid enginesOil canBack pressure

The invention provides an oil way throttling device of a compressor, the compressor and an air conditioner, the oil way throttling device of the compressor comprises a main supporting seat, a first throttling channel and a throttling mechanism, the first throttling channel is arranged on the main supporting seat so that oil can flow, the throttling mechanism is arranged in the first throttling channel, and the throttling mechanism is arranged on the main supporting seat. The throttling mechanism can control the change of the throttling degree according to the rotating speed of a rotating shaft of the compressor, and then the pressure of the oil is controlled to change. The throttling capacity of the throttling mechanism is automatically adjusted through the rotating speed, the throttling capacity is weakened during high-frequency operation to avoid excessive back pressure, and the throttling capacity is enhanced during low-frequency operation to avoid energy efficiency reduction, so that the problem that the pressing force of the dynamic and static vortex plates is too large can be solved, and the problem that the movable vortex plates overturn can also be solved.

Owner:GREE ELECTRIC APPLIANCES INC

A method for combusting coal gasification semi-coke particles using thick and thin thick and fine depth separation and controllable vortex stable combustion technology

InactiveCN106556007BFire stablePrevent high temperature corrosionFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberSlag

A method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies is characterized in that low-rank coal primary air semi-coke powder flow carrying gasified semi-coke is subjected to concentrated-dilute separation to obtain concentrated-phase semi-coke powder flow and dilute-phase semi-coke powder flow; the concentrated-phase semi-coke powder flow is subjected to coarse-fine separation to obtain concentrated-phase coarse semi-coke powder flow and concentrated-phase fine semi-coke flow; the dilute-phase semi-coke powder flow and secondary air are mixed, and the mixture is guided into an outer-layer nozzle of a combustion chamber; and the concentrated-phase fine semi-coke powder flow and the concentrated-phase coarse semi-coke powder flow are guided into an inner-layer nozzle and an intermediate-layer nozzle of the combustion chamber respectively and then sprayed into the combustion chamber, a controlled vortex bluff body device and an auxiliary aeration secondary air nozzle are mounted in the inner-layer nozzle of the combustion chamber, and during ignition, the concentrated-phase fine semi-coke powder flow sprayed by the inner-layer nozzle of the combustion chamber is ignited at first. The method can effectively improve ignition, combustion and burn-out characteristics of gasified semi-coke, reduces pollutant discharge and can effectively prevent a furnace wall from slag-bonding and a water wall from high-temperature corrosion.

Owner:CHONGQING UNIV

A kind of thermoplastic micro-airbag polymer elastomer material and preparation method thereof

The invention relates to a thermoplastic micro-airbag polymer elastomer material and a preparation method thereof. The thermoplastic micro-airbag polymer elastomer material includes the following components in weight percentage: supporting skeleton polymer material 0.1-97%, pressure-resistant and slow-rebound 0.1-97% of the polymer material, 0.01-0.5% of the nucleating agent, and 0.1-10% of the foaming agent; the supporting skeleton polymer material is a polymer material with high molecular weight, high hardness, high crystallization or high polarity, so The pressure-resistant slow-rebound polymer material is a low molecular weight, low hardness, low crystallization to amorphous, low polar / non-polar polymer material corresponding to the supporting skeleton polymer material. Compared with the prior art, the polymer elastomer material prepared by the present invention has an intertwined network formed by the micro-airbag structure and open cells to form an interpenetrating structure, excellent material properties such as resilience, neat cushioning and feedback, and a sense of touch and comfort. High, controllable expansion ratio, etc.

Owner:NANTONG DE NEW MATERIAL CO LTD

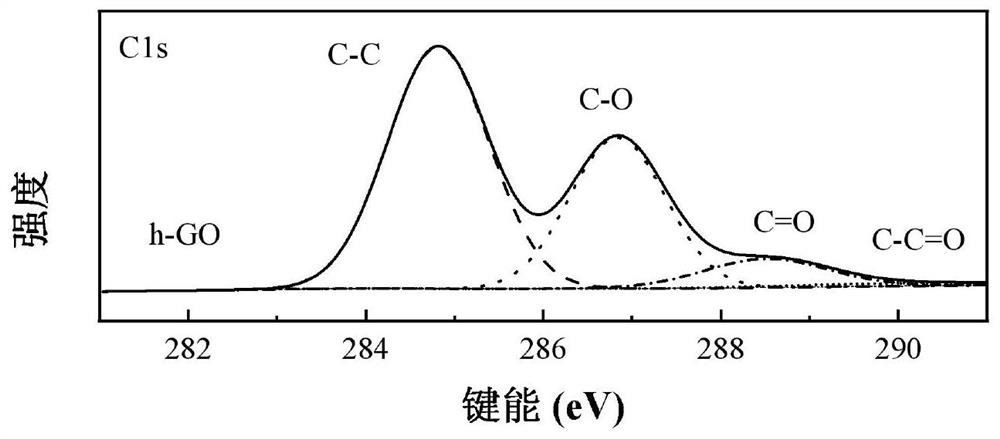

A kind of preparation method of graphene oxide paper with holes reinforced by dendrimers

ActiveCN110903506BEffective resizingEfficient dischargeCarbon compoundsPorous graphenePolymer science

The invention discloses a preparation method of dendritic macromolecule reinforced graphene oxide paper with holes, and belongs to the technical field of graphene oxide production. The invention aimsto solve the problems of low tensile strength and stress relaxation of a graphene oxide film / paper material and low quality of the finally prepared material due to impermeability of lamellas and the like. An epoxy functional group and adjacent carbon atoms thereof are eroded in a graphene oxide sheet layer through the strong oxidizing property of hydrogen peroxide to form nanoscale holes; polyamide-amine (PAMAM) dendritic polymer is introduced to form covalent cross-linking among graphene oxide sheet layers to improve the interlayer bonding strength of the graphene oxide; and finally, a graphene oxide film / paper material with relatively high strength and relatively good quality is obtained by means of directional filtering. The method is simple to operate, low in cost and high in efficiency, and is expected to realize large-scale preparation.

Owner:HARBIN INST OF TECH

Thermoplastic micro-balloon polymeric elastomer material and preparation method thereof

The invention relates to a thermoplastic micro-balloon polymeric elastomer material and a preparation method thereof. The thermoplastic micro-balloon polymeric elastomer material comprises, by weight,0.1-97% of a support frame polymeric material, 0.1-97% of a pressure-resistant slow-recovery polymeric material, 0.01-0.5% of a nucleating agent and 0.1-10% of a foaming agent. The support frame polymeric material is a high-hardness, high-crystallinity or high-polarity polymeric material; the pressure-resistant slow-recovery polymeric material is low-hardness low-crystallinity amorphous low-polarity / nonpolar polymeric material corresponding to the support frame polymeric material. Compared with the prior art, the thermoplastic micro-balloon polymeric elastomer material has the advantages that, for instance, a tangled network formed by micro-balloon structures and open cells forms mutual-penetrating structure, the material properties, such as recovery, are excellent, buffering feedback isclear, good tough and comfort are provided, and expansion rate is controllable.

Owner:NANTONG DE NEW MATERIAL CO LTD

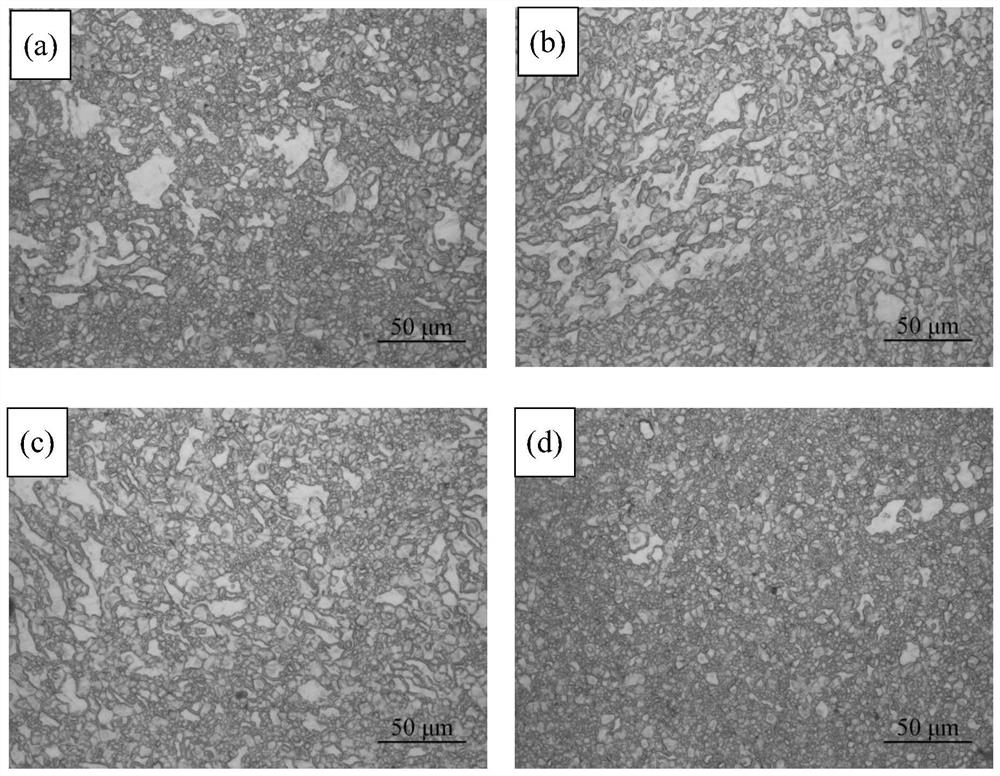

Methods of regulating grain structure and improving properties of zk60 wrought magnesium alloy

The invention relates to the technical field of wrought magnesium alloys, and specifically provides a method for regulating and improving the grain structure of ZK60 wrought magnesium alloys. The method of the invention comprises that after the ZK60 wrought magnesium alloy to be treated is subjected to solid solution treatment, the stepwise heating and pre-aging treatment is carried out, and then the extrusion treatment is carried out. This method can effectively control the grain size of ZK60 magnesium alloy by adding stepped pre-aging treatment, significantly improve the strength and plasticity of the material, fully exploit the advantages of low density and high specific strength of ZK60, and realize the promotion and application of ZK60 magnesium alloy in new energy buses. And the core problem of the lightweight goal of automobiles, laying the foundation for the promotion and application of ZK60 magnesium alloy in new energy buses.

Owner:QILU UNIV OF TECH +1

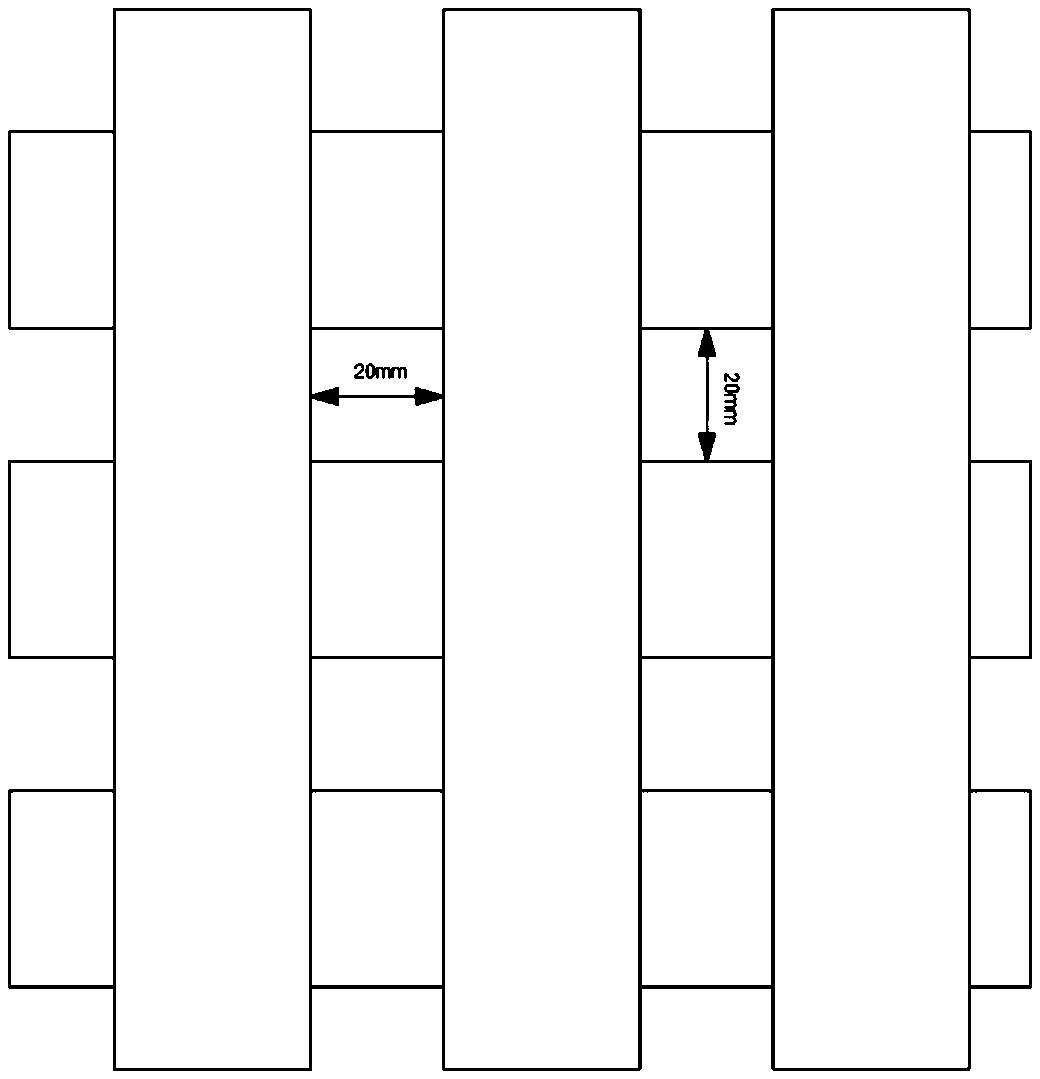

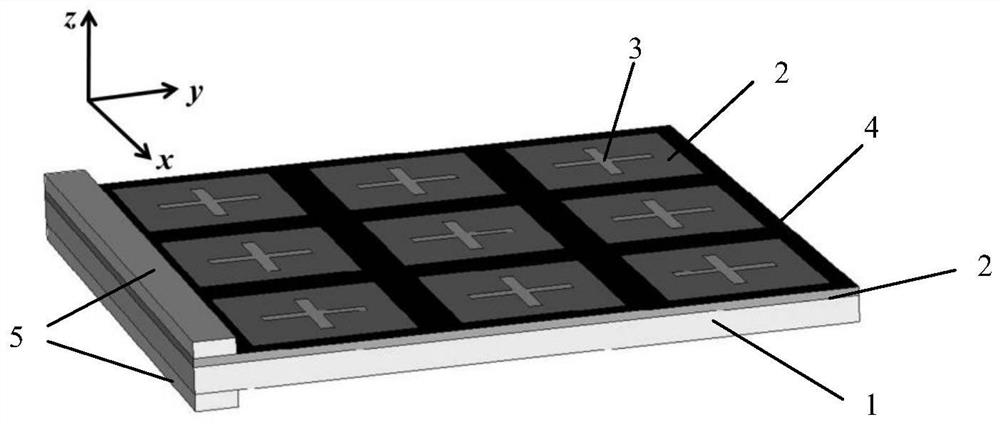

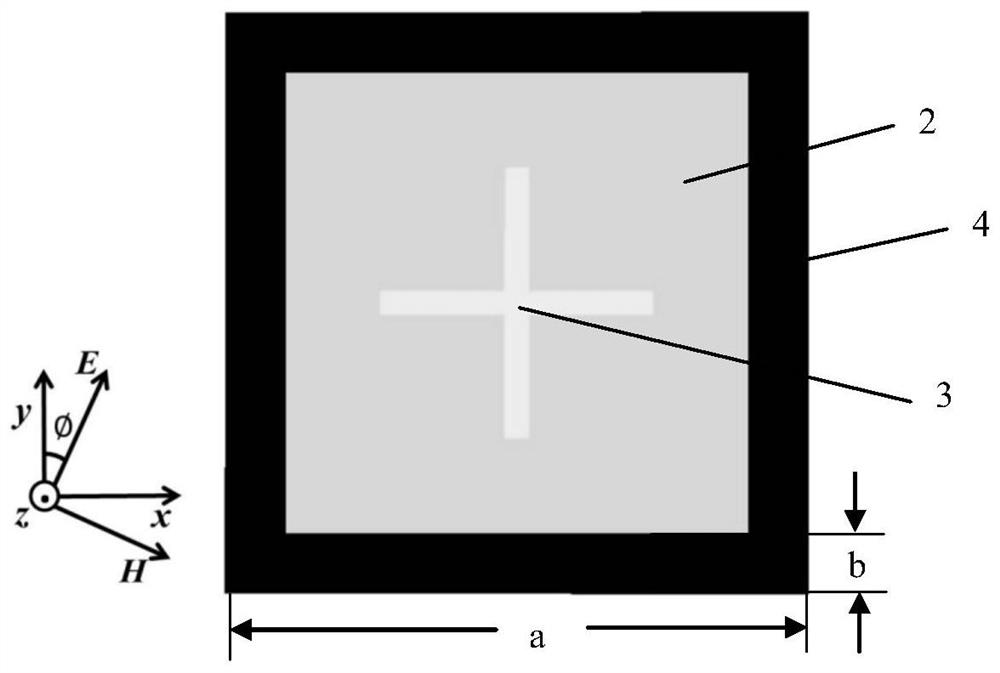

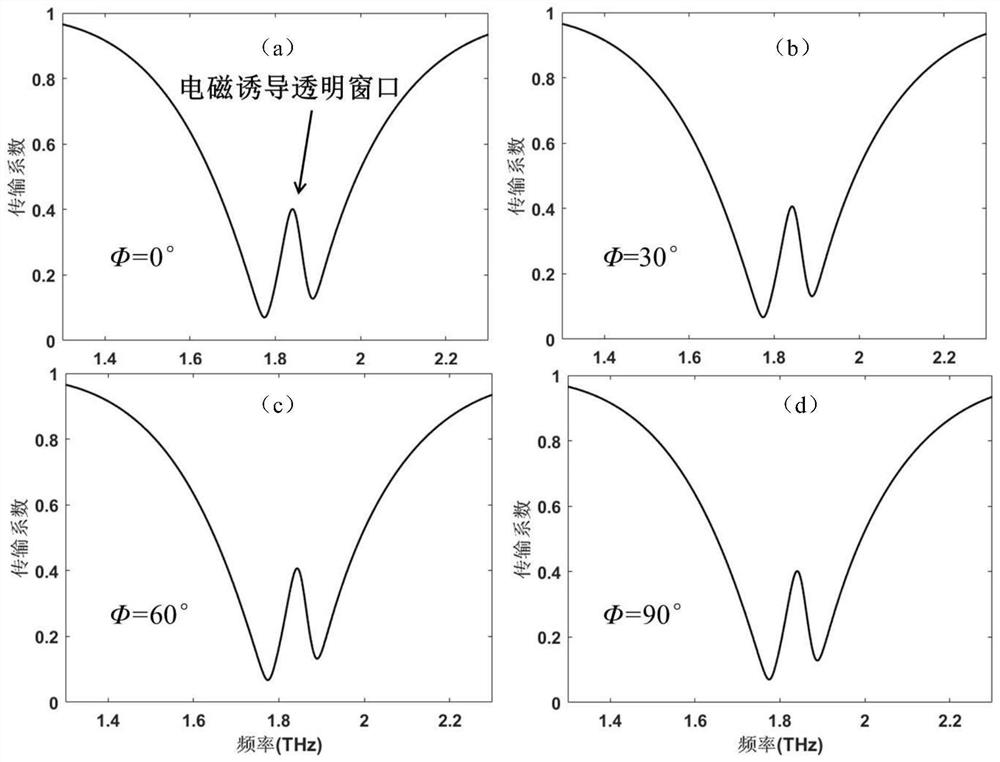

A polarization-insensitive tunable electromagnetically induced transparent terahertz device

ActiveCN110246956BSymmetricalEffective resizingSuperconductor detailsDissimilar materials junction devicesExternal biasMetal electrodes

The invention belongs to the field of metamaterial structures, in particular to a polarization-insensitive tunable electromagnetically induced transparent terahertz device. The device is composed of a substrate, a graphene layer, a metal layer and a metal electrode; the substrate includes a silicon layer and a silicon dioxide layer covering the silicon layer; the graphene layer covers the upper surface of the silicon dioxide layer , and the graphene layer is composed of periodically arranged graphene frame structures; the metal layer covers the upper surface of the silicon dioxide layer, and the metal layer is composed of periodically arranged cross-shaped metal unit structures; One electrode of the metal electrode is arranged at the edge of the graphene layer and connected with the graphene layer, and the other electrode is arranged at the edge of the silicon layer and connected with the silicon layer. The invention can realize electromagnetically induced transparency and generate slow light effect. The invention can realize the regulation of the transmission characteristics and slow light effect of metamaterial devices by applying external bias voltage, and effectively adjust the size of the group delay.

Owner:NAT UNIV OF DEFENSE TECH

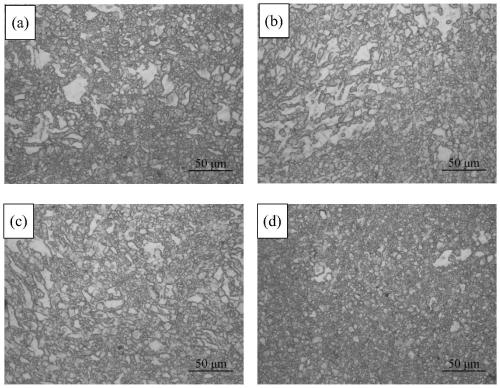

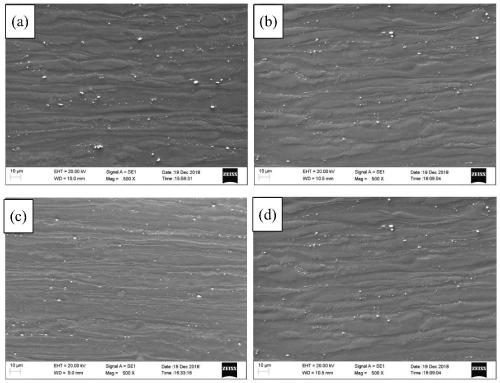

A kind of preparation method of fe-si-al soft magnetic material with high microwave magnetic permeability

InactiveCN102623122BIncrease the complex permeability μIncrease the value of the complex permeability μInorganic material magnetismMicrowaveMass ratio

The invention discloses a preparation method of Fe-Si-Al soft magnetic material with high microwave magnetic permeability, which belongs to the field of high-frequency magnetic performance magnetic materials. The present invention includes the following steps: 1) 100-mesh Fe-Si-Al raw powder is sieved through 100-mesh, 200-mesh, and 300-mesh sieves in turn, and the 75 μm-150 μm powder is called A type powder, and the 48 μm-75 μm powder is called B type. Powder; the mass percent of the Fe-Si-Al raw powder component is: Fe: (82.6-x-y)%, Si: (10.3+x)%, Al: (7.1+y)%, |x|≤ 0.7, |y|≤1.7; 2) Flake treatment, control the average particle size / thickness ratio of the powder between 14 and 26; 3) Remix according to the mass ratio of Class A: Class B = 0.5 to 2 to obtain high Microwave permeability soft magnetic alloy powder. The invention has simple process and convenient operation, and the Fe-Si-Al alloy powder is sieved before mechanical ball milling, which can improve its microwave magnetic permeability, and can greatly increase its microwave magnetic permeability if it is further processed into flakes.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

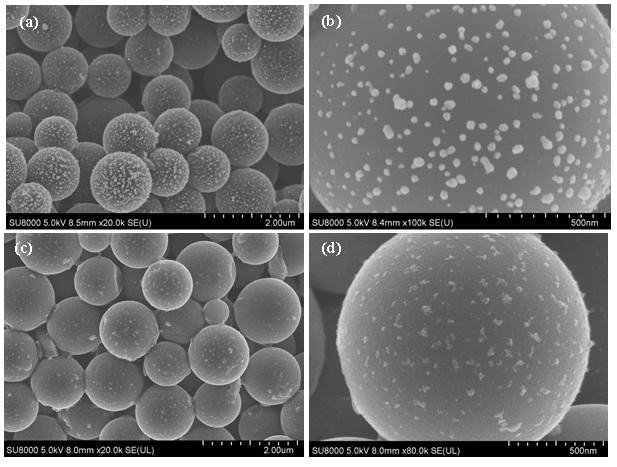

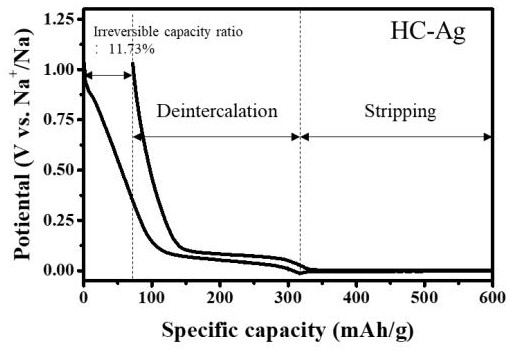

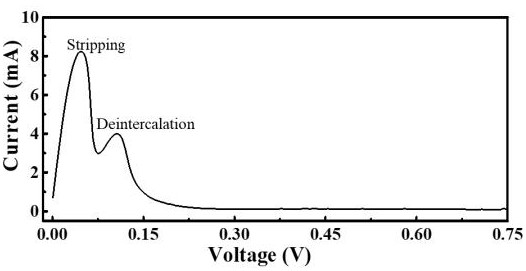

A sodium storage hard carbon anode based on an intercalation-electroplating hybrid mechanism and its preparation method

ActiveCN113540408BUniform depositionIncrease capacityElectrode thermal treatmentFinal product manufactureCarbon filmThin film electrode

Owner:FUJIAN NORMAL UNIV

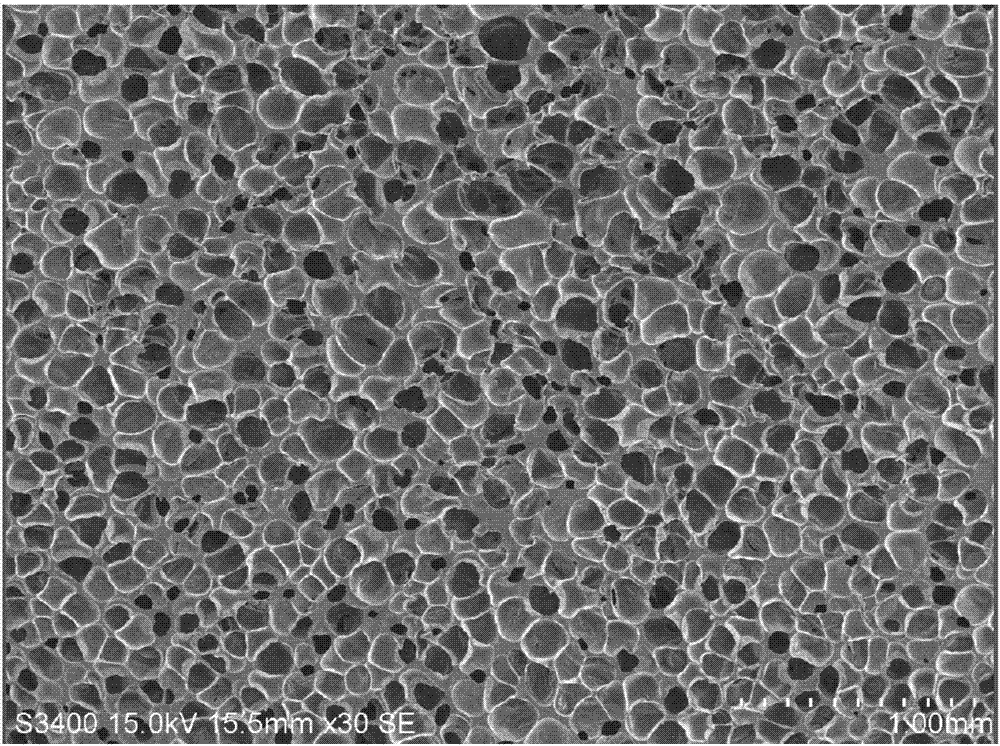

A kind of micro-diameter thermoplastic micro-airbag polyurethane elastomer material and preparation method thereof

ActiveCN107298848BIncrease elasticityImprove energy absorption and storageThermoplasticPolyurethane elastomer

The invention relates to a thermoplastic micro-airbag polyurethane elastomer material with microparticle size and a preparation method thereof. The polyurethane elastomer material includes the following components in weight percentage: supporting skeleton polymer material 1-97%, pressure-resistant and slow-recovery Elastic polymer material 1-97%, nucleating agent 0.01~0.5%, blowing agent 0.1~10%; it is made by the following method: (1) polymer raw material and nucleating agent are fed from the front end of twin-screw extruder The feeding port is fed, and the foaming agent is fed from the feeding port in the middle section, so that all raw materials are hot-melted and mixed fully, and then enter the static mixer for further homogenization, and then are pressure-controlled and quantitatively transported by the melt pump; (2) The hot melt sent out by the melt pump enters the underwater pelletizing chamber through the die head to be pelletized, and is taken out by the process water for separation, and the obtained pellets are screened and dried to obtain the target product. Compared with the prior art, the product of the present invention has an intertwined network airway interpenetrating structure formed by a suitable micro-airbag structure and moderate open cells, and the particle size can be effectively controlled at about 0.5-2mm.

Owner:NANTONG DE NEW MATERIAL CO LTD

Arc-shaped plate fixed-distance conveying method for ampoules

InactiveCN104944142AImprove protectionReduce the intensity of the agitationConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses an arc-shaped plate fixed-distance conveying method for ampoules. By the adoption of an arc-shaped plate fixed-distance conveying device for ampoules, fixed-distance conveyance of ampoules is achieved. The method comprises the steps of 1, adjusting the distance between a first arc-shaped protective plate and a second arc-shaped protective plate on a trough base plate according to the size of the ampoules to be conveyed, and fixing the first arc-shaped protective plate and the second arc-shaped protective plate through bolts and nuts below the trough base plate; 2, placing the ampoules on the trough base plate, conveying the ampoules to a conveyer belt through a guiding channel formed by the first arc-shaped protective plate and the second arc-shaped protective plate, limiting the distance between the conveyed ampoules through ampoule clamping blocks on the conveyer belt, and finally conveying the ampoules with distance well limited out. The method is suitable for conveying ampoules in different specifications and sizes and has the advantages that the ampoules can be well protected and ampoule conveyance efficiency is not affected.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

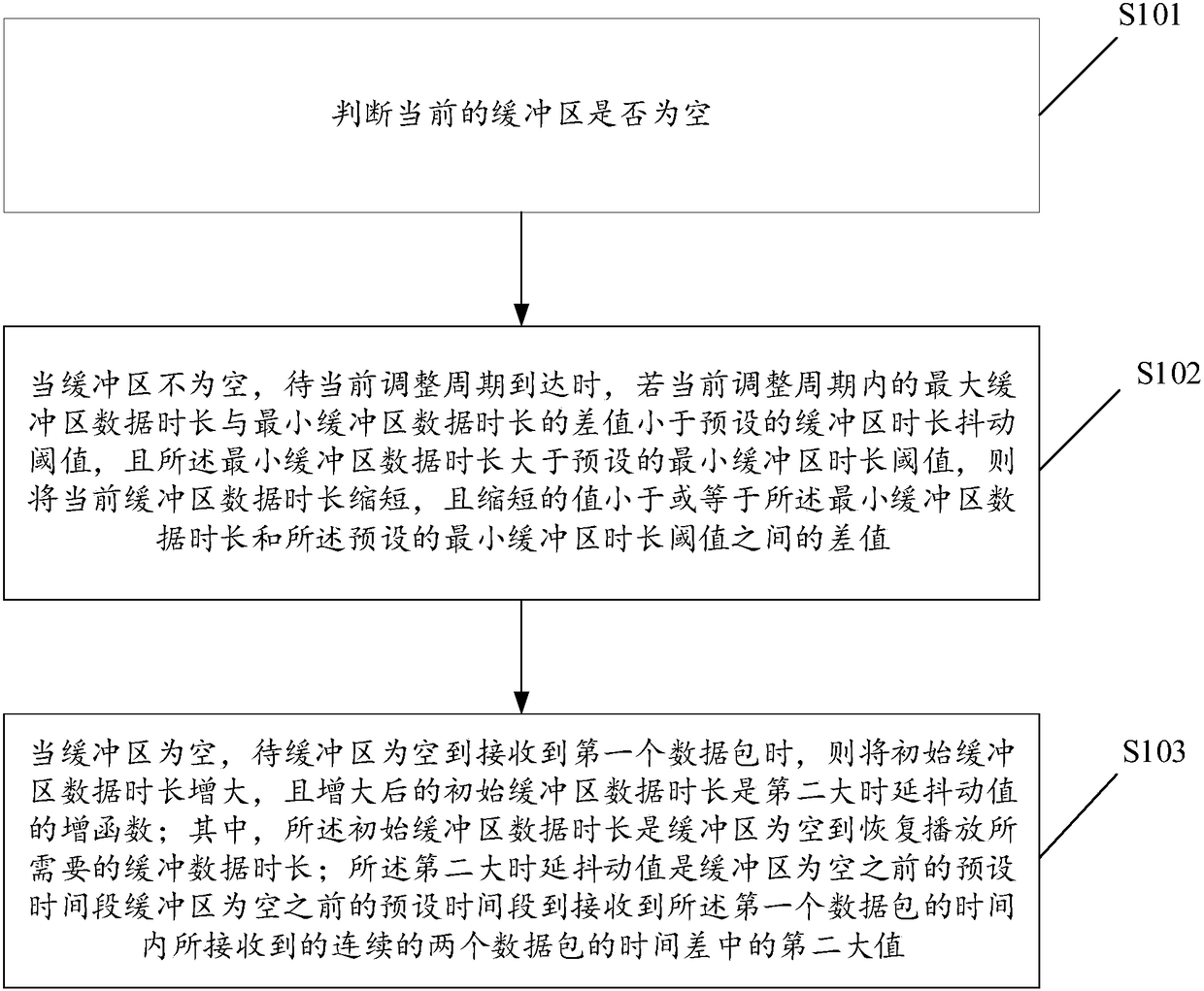

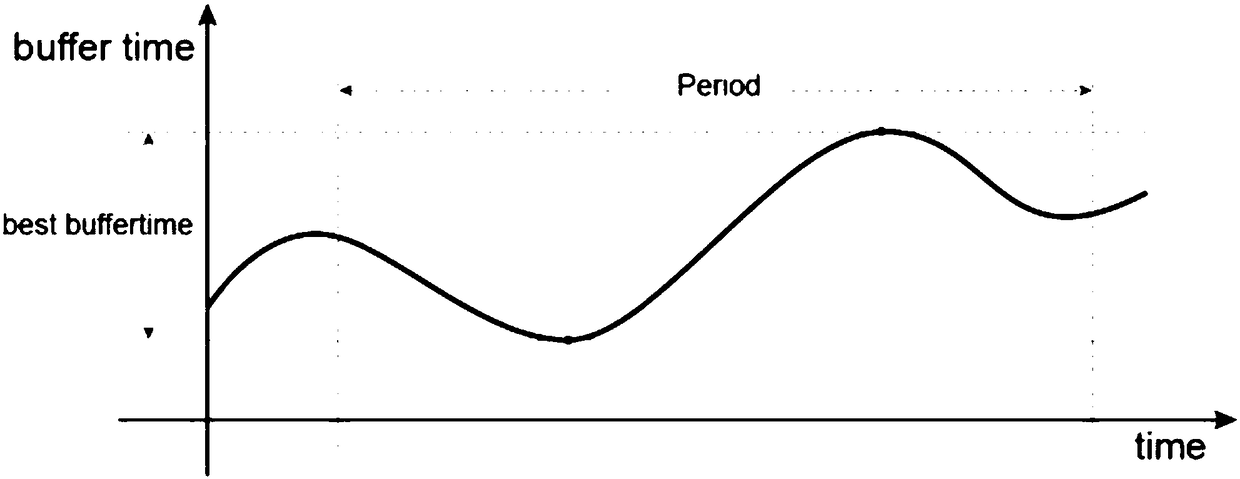

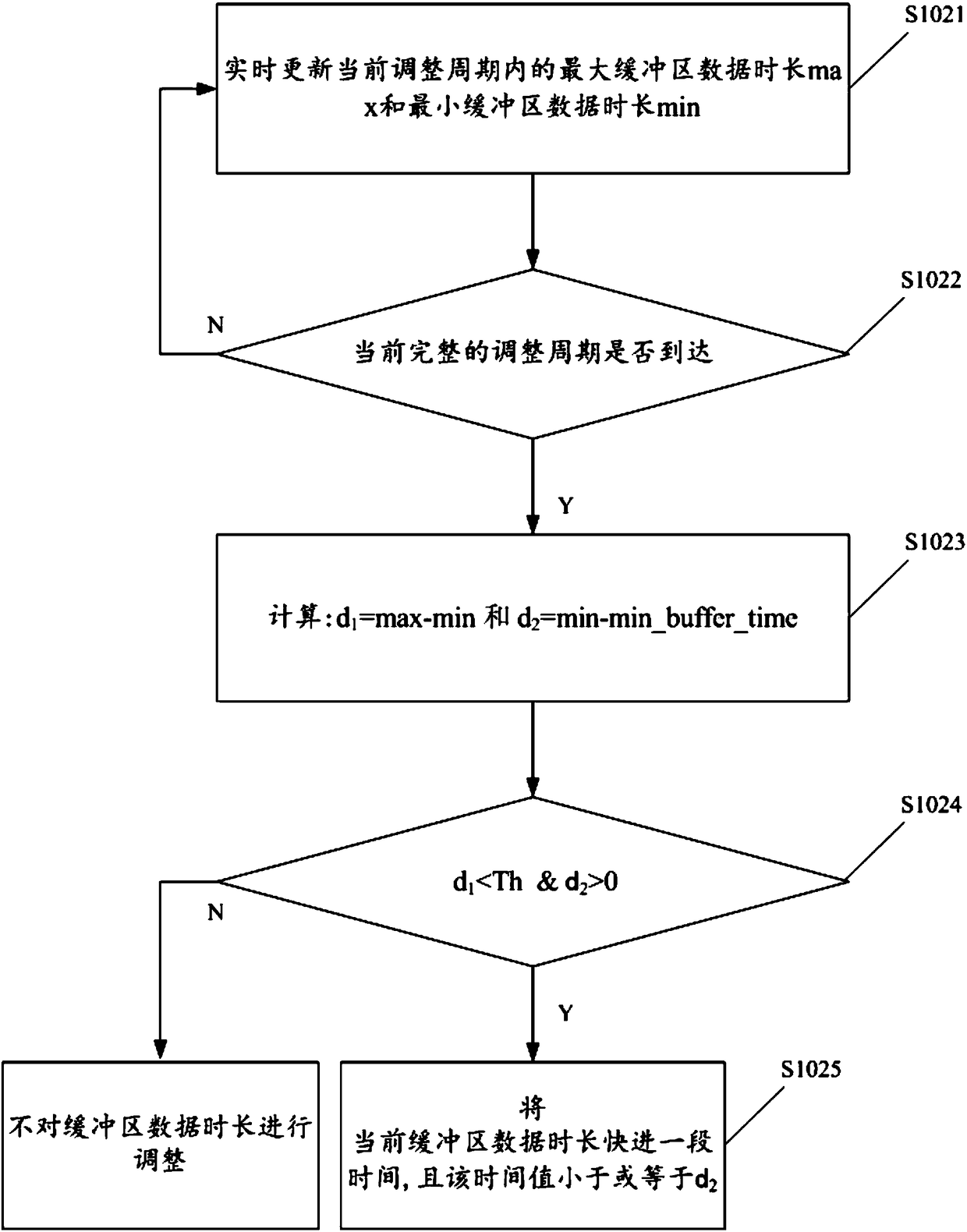

Audio/video live broadcast method and device, and control method and device

ActiveCN105142002BSolve the delay problemFix jitterSelective content distributionTime segmentComputer science

The invention discloses a control method for delay jitter removal based on a TCP live broadcasting system. The control method comprises the steps of: judging whether a current buffer region is empty; if not, shortening the data duration of the current buffer region when a current adjustment period arrives and if a difference between the maximum buffer region data duration and the minimum buffer region data duration in the current adjustment period is smaller than a preset buffer region duration jitter threshold and the minimum buffer region data duration is greater than a preset minimum buffer region duration threshold; if the current buffer region is empty, enlarging an initial buffer region data duration when the empty buffer region receives a first data packet, wherein the enlarged initial buffer region data duration is an increasing function of a second biggest delay jitter value, the initial buffer region data duration is the buffer data duration needed by the buffer region from being empty to play-recovering, and the second biggest delay jitter value is a second biggest value of time differences of reception of two continuous data packets from a period of time before the buffer region is empty to the time when the first data packet is received.

Owner:GUANGZHOU BOGUAN TELECOMM TECH LTD

Method for regulating and controlling grain structure of ZK60 wrought magnesium alloy and improving performance of ZK60 wrought magnesium alloy

The invention relates to the technical field of wrought magnesium alloys, and particularly provides a method for regulating and controlling the grain structure of a ZK60 wrought magnesium alloy and improving the performance of the ZK60 wrought magnesium alloy. The method comprises the steps of carrying out solution treatment on the ZK60 wrought magnesium alloy to be treated, carrying out stepped heating pre-aging treatment, and then carrying out extrusion treatment. According to the method, the stepped pre-aging treatment is added, the grain size of the ZK60 magnesium alloy can be effectivelyregulated and controlled, the strength and plasticity of a material are remarkably improved, the advantages of low density and high specific strength of the ZK60 wrought magnesium alloy are fully explored, the core problems of application and popularization of the ZK60 magnesium alloy in new energy buses and automobile lightening targets can be solved, and a foundation is laid for application andpopularization of the ZK60 magnesium alloy in new energy buses.

Owner:QILU UNIV OF TECH +1

Degradable antifouling thermoplastic micro-airbag polymer elastomer material and preparation method thereof

ActiveCN109320951AImprove conductivityHigh conductivity material surface polarityCoatingsThermoplasticElastomer

The invention relates to a degradable antifouling thermoplastic micro-airbag polymer elastomer material and a preparation method thereof. The preparation method specially comprises the following steps: (1) feeding a polymer raw material, a nucleating agent and an environment-friendly degradable organic perfluorinated material from a feed opening in the front end of a twin-screw extruder, feeding afoaming agent from a feeding opening in the middle section of the twin-screw extruder, after all the raw materials are hot-melted and mixed sufficiently, feeding the mixture into a static mixer for further homogenizing, and then performing pressure control and quantitative transporting by a melt pump; and (2) enabling a hot melt pumped out from the melt pump to enter an underwater granulating chamber for granulating through a die head, separating the granulated hot melt from process water, and screening and drying the obtained particles, thereby forming a target product. Compared with the prior art, the performances of the antifouling property, the dirt resistance, the oil resistance, the contamination prevention property, the aesthetic appearance, and good tactile impression of the material can be effectively realized, and the degradable antifouling thermoplastic micro-airbag polymer elastomer material is especially suitable for being applied in the fields such as shoe materials andfood package.

Owner:NANTONG DE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com