A sodium storage hard carbon anode based on an intercalation-electroplating hybrid mechanism and its preparation method

A hard carbon and negative electrode technology, applied in the field of sodium storage hard carbon negative electrode and its preparation, can solve the problems of fast cycle decay of sodium metal negative electrode, uncontrollable growth of dendrites, unstable SEI film and large volume change, etc. Performance, the effect of low experimental temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

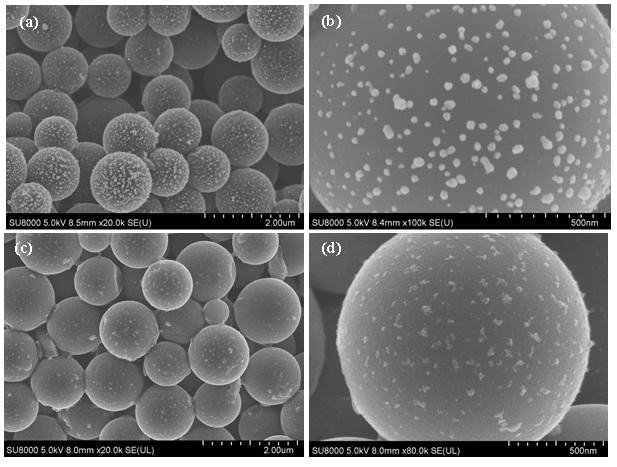

[0022] A high-capacity sodium storage hard carbon negative electrode based on embedding-plating mixing mechanism, the specific preparation method includes the following steps:

[0023] (1) Weigh the chlorinated choline and urea with a molar ratio of 0.5: 1 and dissolve at 60 ° C to form a colorless transparent ionic liquid, and then add AgNO 3 Stir until completely dissolved to give an ionic liquid containing Ag ions; wherein AgNO 3 The amount added accounts for the concentration of the ionic liquid at 0.05mol / L;

[0024] (2) The hard carbon (purchased from Shenzhen Kejing Co., Ltd.): CMC = 85:15 (mass ratio) is mixed and ground and evenly coated at 1.2 cm 2 The copper foil is used as the substrate, and after drying at 100 °C, it is cut into a square pole piece of 1.2cm*2.5cm;

[0025] (3) The cropped polar piece is placed in an ionic liquid, at a temperature of 25 °C, a constant voltage of 2.5V, and electrodeposition is 3min to obtain HC-Ag material.

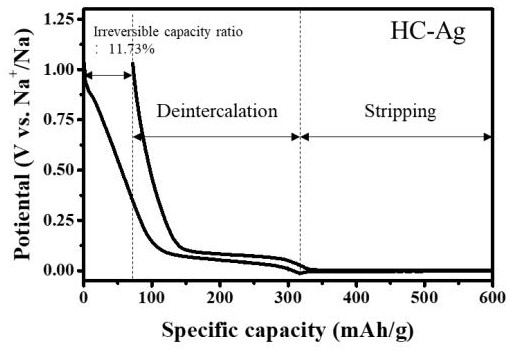

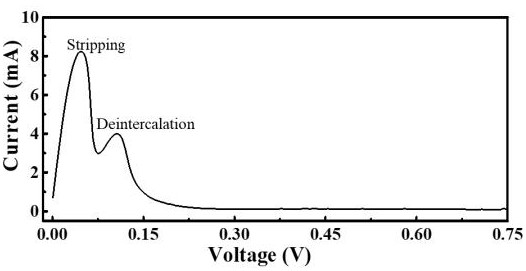

[0026] Sodium metal battery ...

Embodiment 2

[0028] A high-capacity sodium storage hard carbon negative electrode based on embedding-plating mixing mechanism, the specific preparation method includes the following steps:

[0029] (1) Weigh the chlorinated choline and urea with a molar ratio of 0.5: 1 and dissolve at 70 ° C to form a colorless transparent ionic liquid, and then add Cu (NO 3 ) 2 Stir until completely dissolved to give an ionic liquid containing Cu metal ions; wherein Cu (NO 3 ) 2 The amount of addition accounts for the concentration of the ionic liquid is 0.075mol / L;

[0030] (2) The hard carbon: CMC = 85: 15 (mass ratio) is mixed and ground and evenly coated at 1.2 cm 2 The copper foil is used as the substrate, and after drying at 100 °C, it is cut into a square pole piece of 1.2cm*2.5cm;

[0031](3) The cropped polar piece is placed in an ionic liquid, at a temperature of 25 °C, a constant voltage of 4V, and an electrodeposition of 5min to obtain HC-Cu material.

[0032] Sodium metal battery assembly: Cut t...

Embodiment 3

[0034] A high-capacity sodium storage hard carbon negative electrode based on embedding-plating mixing mechanism, the specific preparation method includes the following steps:

[0035] (1) Weigh the molar ratio of 0.5: 1 choline chloride and urea at 80 °C heating dissolved stirring to form a colorless transparent ionic liquid, and then add AgNO 3 Stir until completely dissolved to give an ionic liquid containing Ag ions; wherein AgNO 3 The amount added accounts for the concentration of the ionic liquid at 0.1mol / L;

[0036] (2) The hard carbon: CMC = 85: 15 (mass ratio) is mixed and ground and evenly coated at 1.2 cm 2 The copper foil is used as the substrate, and after drying at 100 °C, it is cut into a square pole piece of 1.2cm*2.5cm;

[0037] (3) The cropped polar piece is placed in an ionic liquid, at a temperature of 25 °C, a constant voltage of 5.5V, and electrodeposition for 8min, HC-Ag material is obtained.

[0038] Sodium metal battery assembly: Cut the prepared HC-Ag to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com