Hollow anchor stock circulating pressure slip casting construction method and special slip casting system thereof

A technology of circulating pressure and grouting system, which is applied in the installation of anchor rods, foundation structure engineering, sheet pile walls, etc., can solve the problems of high cost of grouting, easy blockage of exhaust pipes, and inability to realize pressure grouting, etc., to achieve improved The effect of engineering quality, low equipment cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

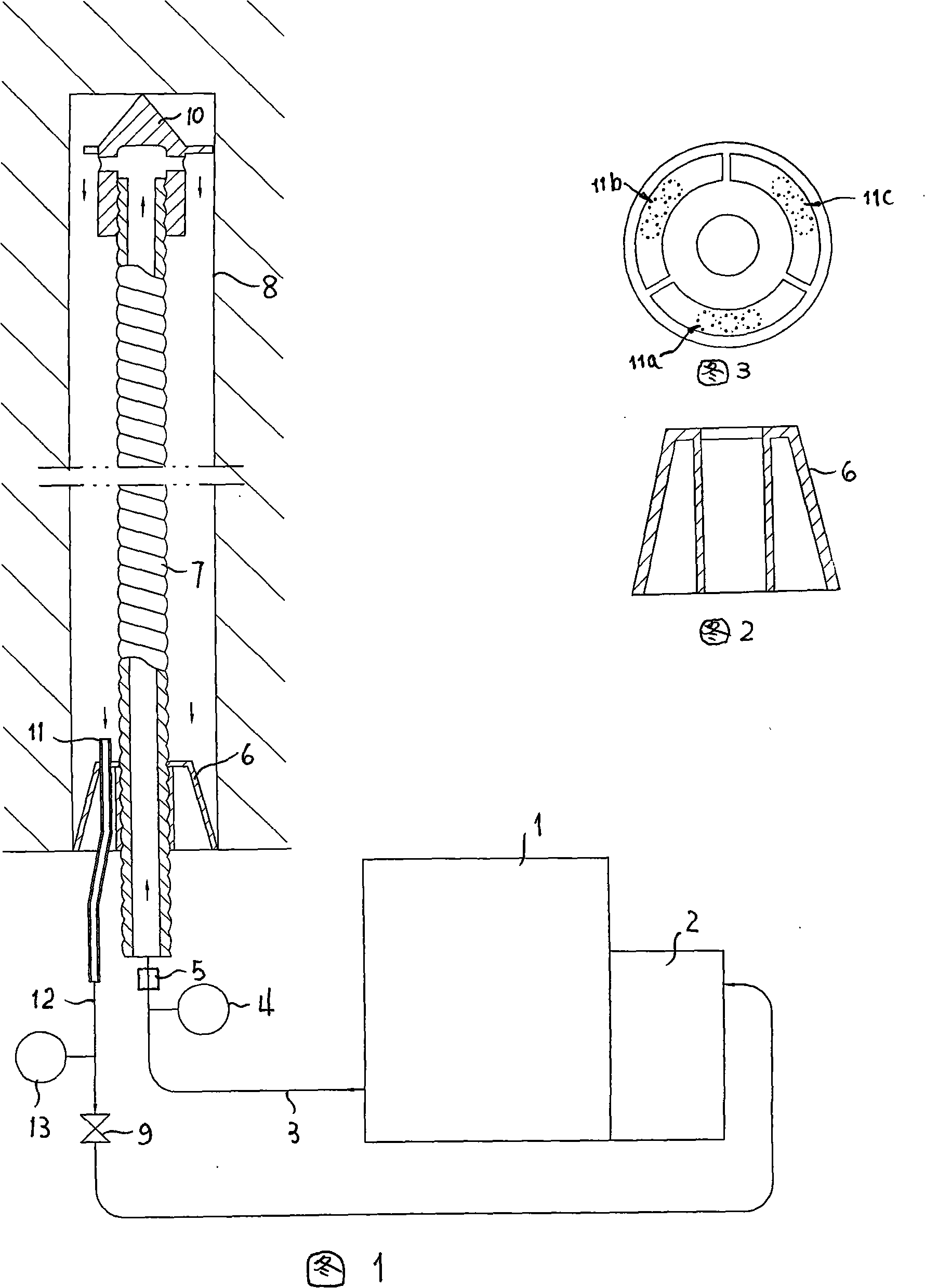

[0021] Referring to Fig. 1, the present invention includes drilling of anchor hole 8, cleaning of anchor hole, installation of hollow anchor rod 7 in the anchor hole, the outer end of the hollow anchor rod is connected to one end of grouting joint 5, and the other end of the grouting joint is connected through grouting pipeline 3 Grouting machine 1 (as CN2220530Y bolt grouting machine), also has the following steps,

[0022] a) Insert the grout return joint 11 from the half slit of the rubber stopper 6 and penetrate into the inner cavity of the hollow anchor rod 7, and the other end of the grout return joint is located outside the anchor hole;

[0023] b), the other end of the slurry return joint 11 extending out of the anchor hole is connected to one end of the slurry return pipeline 12, and the other end of the slurry return pipeline 12 extends above the material level in the slurry reservoir 2 of the grouting machine 1;

[0024] c) Start the grouting machine 1, the slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com