Machining device suitable for cutting round stainless steel sheet

A stainless steel sheet and processing device technology, applied in auxiliary devices, metal processing, metal processing equipment, etc., can solve the problems of stainless steel plate material waste, manual movement of plates, etc., and achieve the effect of improving utilization rate, mechanization of operation, and improvement of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

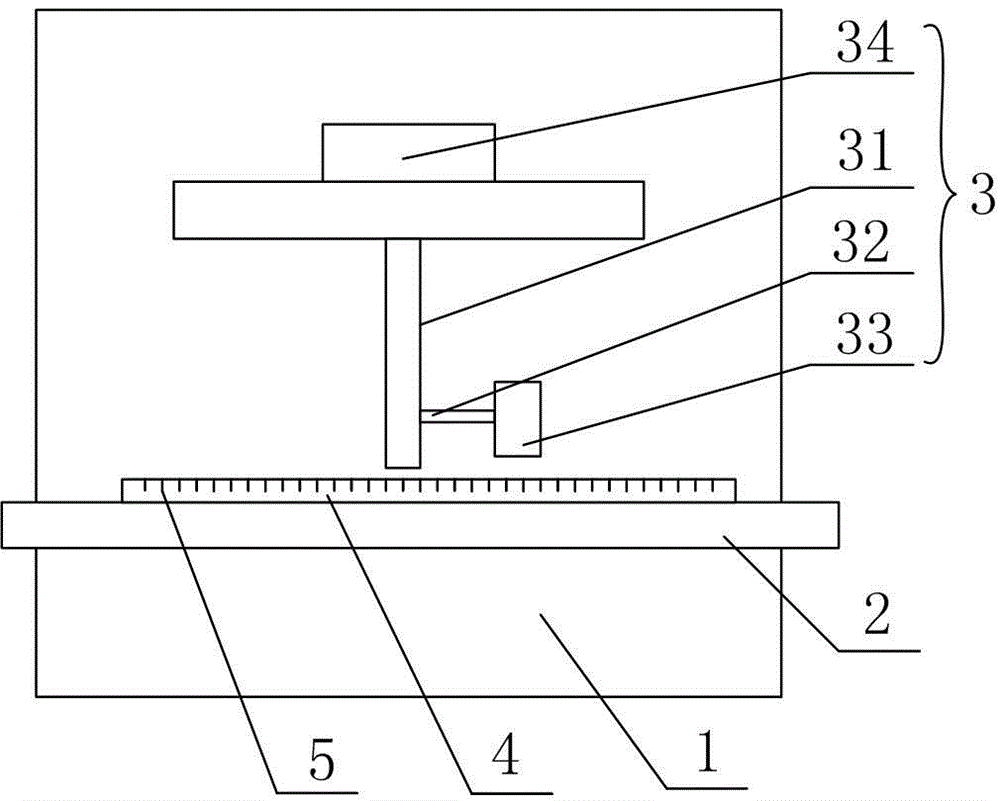

[0032] Processing equipment suitable for cutting round stainless steel sheets, such as figure 1 , figure 2 and image 3 As shown, it includes a cutting machine mounting frame 1, a plate fixing platform 2 and a plasma cutting mechanism 3 arranged on the cutting machine mounting frame 1;

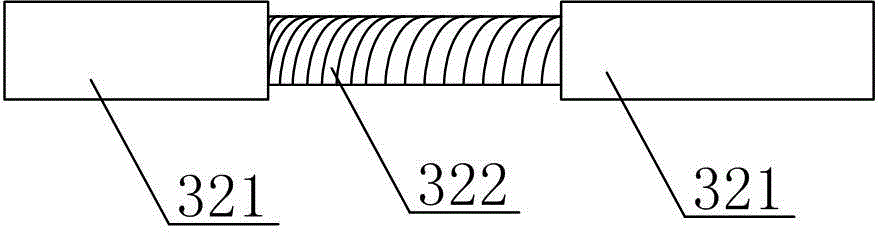

[0033] Described plasma cutting mechanism 3 comprises the rotary bar 31 that top is connected on the cutting machine installation frame 1, the plasma cutting head 33 that is fixed on the bottom end of rotary bar 31 by transverse extension bar 32, and the drive motor 34 that drives rotary bar 31 to rotate; The transverse extension rod 32 includes an inner rod 321 provided with an external thread, and two outer rods 322 provided with an outer rod 322; one end of one of the outer rods 322 is threadedly connected with the inner rod 321, and the other end is connected with the bottom end of the rotating rod 31 For fixed connection, one end of the other outer rod 322 is threadedly connected with ...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that in this embodiment, the structure of the limit block 4 and the scale 5 is added, and the specific setting method is as follows:

[0036] The plate fixing platform 2 is provided with a limit block 4; the limit block 4 is provided with a scale 5.

Embodiment 3

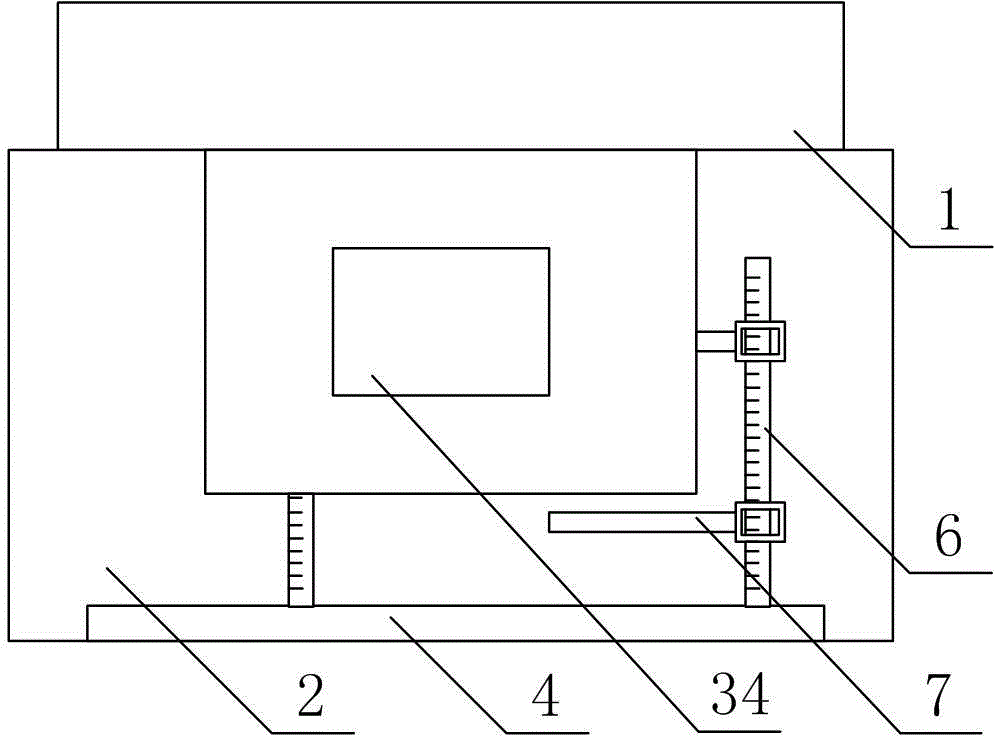

[0038] The difference between this embodiment and embodiment 2 is: the structure of pointer 6 and marking rod 7 is added in this embodiment, and the specific setting method is as follows:

[0039] The limiting block 4 is also provided with a chute, and two pointers 6 parallel to each other are installed in the chute, and the pointers 6 are located in a plane parallel to the plate fixing platform 2 and perpendicular to the chute. The pointer 6 is also provided with a scale, and a marking rod 7 perpendicular to the pointer 6 is sleeved thereon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com