Automatic discharging, moving and swinging device of geological exploration drill pipe

An automatic drainage and geological exploration technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of low installation flexibility, time-consuming and labor-intensive, affecting production and use, and achieve a high degree of automation, increase the selection range, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The following is a description of Embodiment 1.

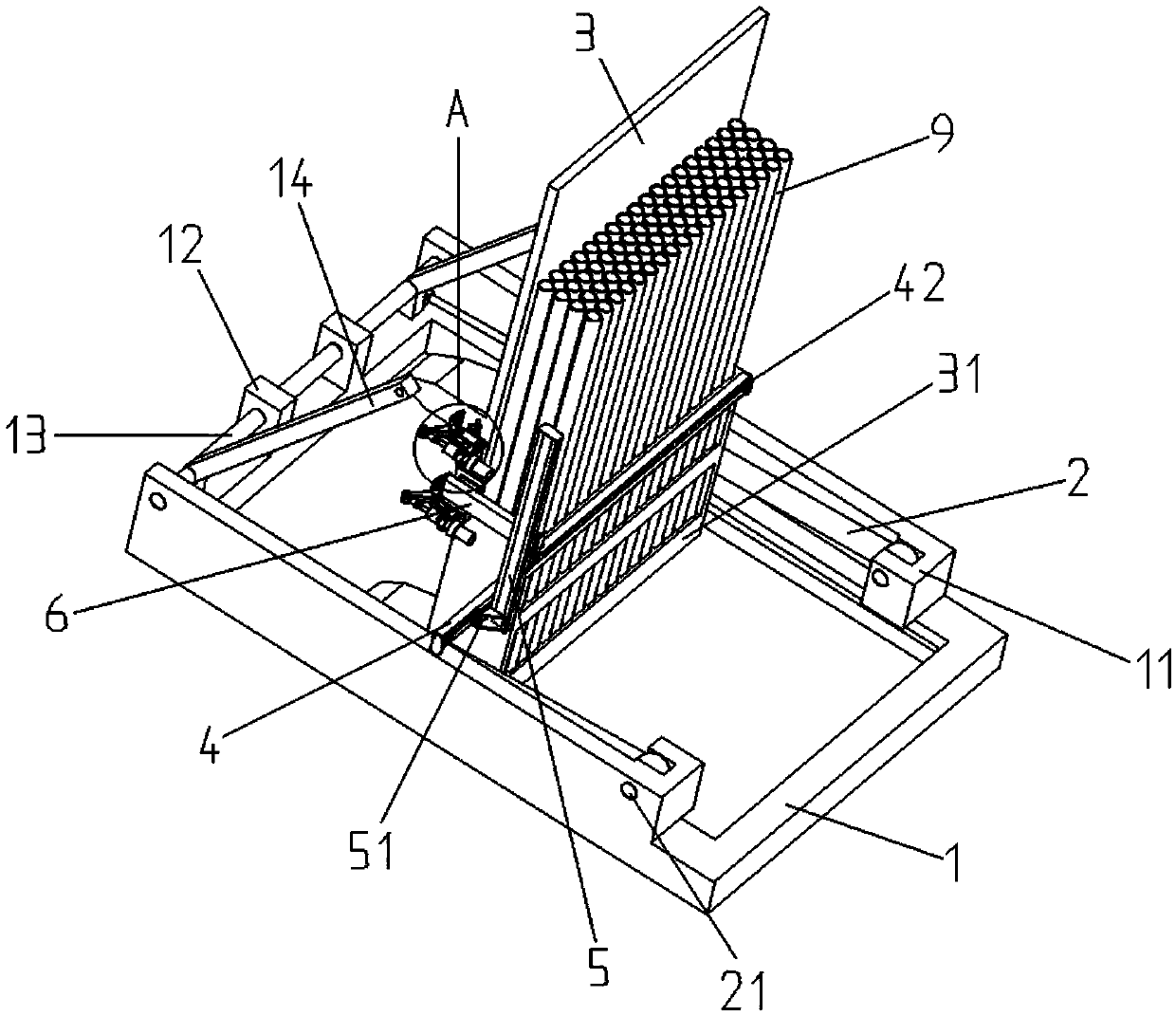

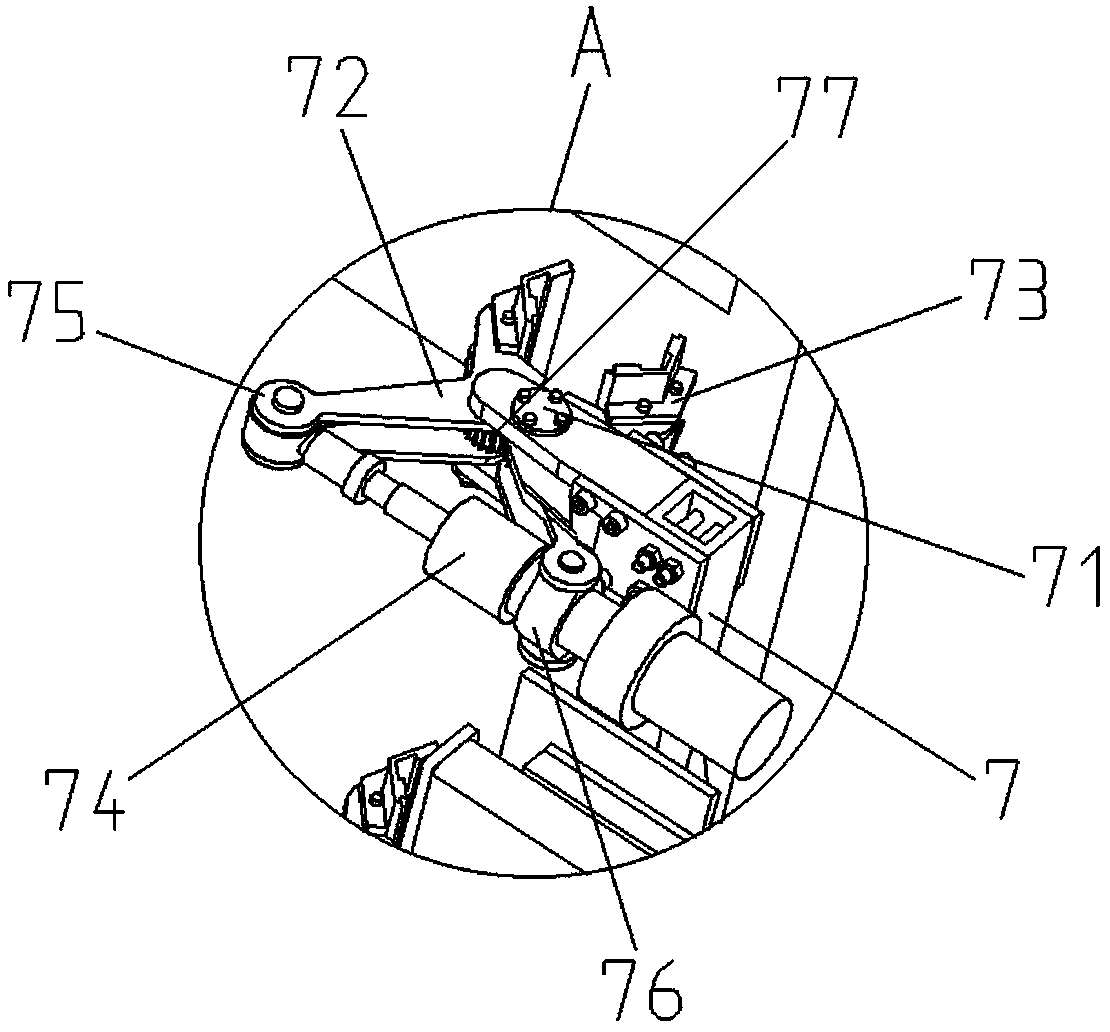

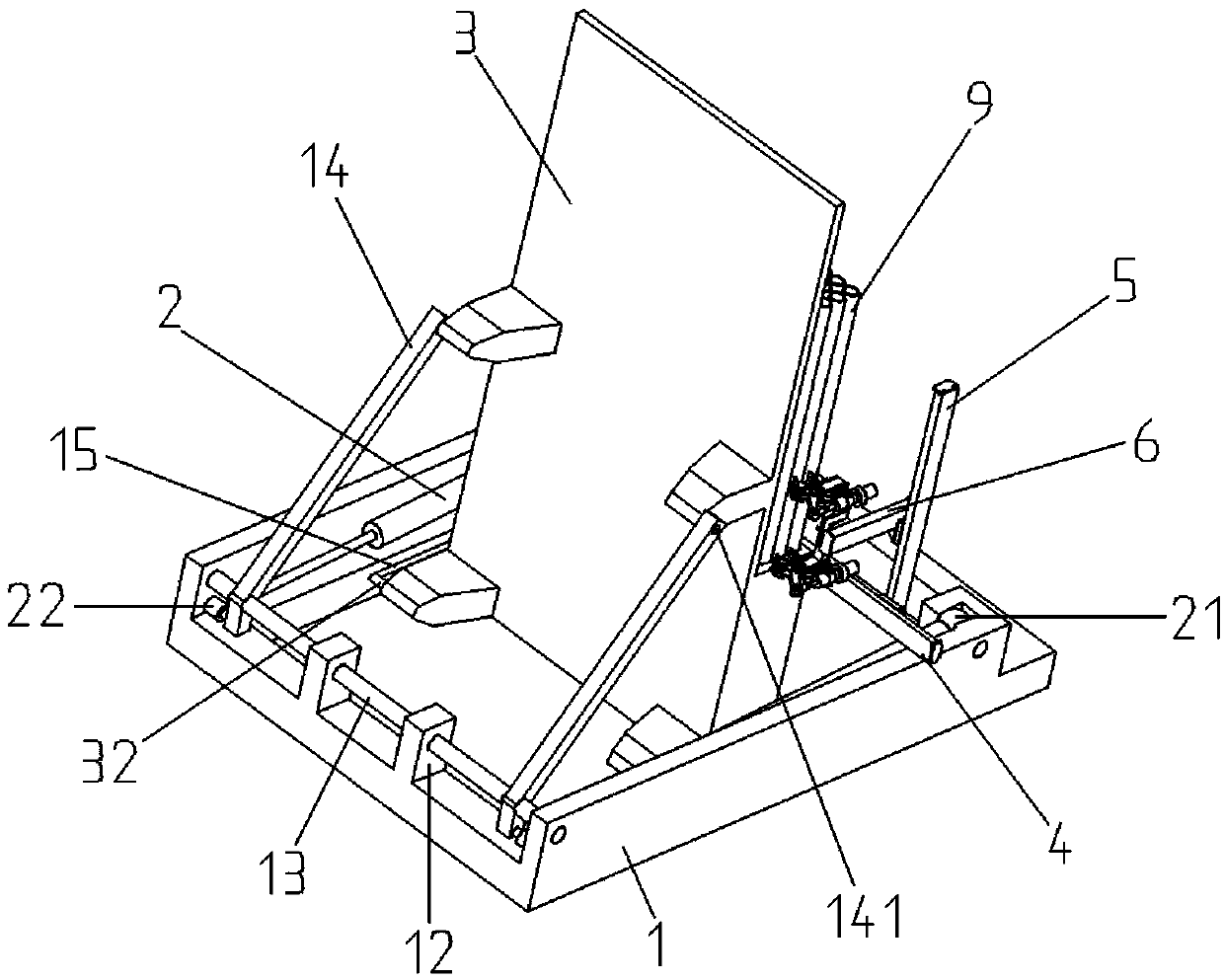

[0037] Such as Figures 1 to 8 As shown, an automatic discharge and swing device for geological exploration drill pipes includes an underframe body 1, a hydraulic cylinder shaft groove 11, an underframe positioning block 12, a support frame shaft 13, a support drive block 131, a vertical support frame 14, Connect the support shaft 141, slide groove 15, vertical drive hydraulic cylinder 2, hydraulic cylinder installation shaft 21, cylinder rod drive shaft 22, drill pipe vertical frame 3, vertical limit frame 31, limit slide rod 32, lateral slide Frame 4, horizontal rotary motor 41, horizontal screw rod 42, vertical sliding frame 5, horizontal slider 51, vertical rotary motor 52, vertical screw rod 53, lateral sliding frame 6, vertical slider 61, lateral rotary motor 62. Lateral screw 63, clamping mounting frame 7, clamping body shaft assembly 71, clamping body power arm 72, clamping claw 73, clamping driving cylinder 74,...

Embodiment 2

[0045] The following is a description of Embodiment 2.

[0046] In embodiment 2, for the same structure as in embodiment 1, the same symbol is given, and the same description is omitted. Embodiment 2 is improved on the basis of embodiment 1. A level sensor module perpendicular to the end face of the drill pipe vertical frame 3 is provided, and the level sensor module is electrically connected to the input end of the single-chip microcomputer control module 8 .

[0047] The benefit of this embodiment is: whether the vertical frame 3 of the drilling rod can be detected in real time by the level sensor module to reach the horizontal state, and sent to the single-chip control module 8 in real time, further controlling the start and stop of the vertically driven hydraulic cylinder 2, greatly The delivery accuracy and practicality of the device are improved.

[0048] When the device is in use, connect the power supply external terminal 92, and the vertical drive hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com