Fast extrusion method of ZK60 magnesium alloy profile

An extrusion method and magnesium alloy technology, which is applied in the direction of metal extrusion, metal extrusion control equipment, metal processing equipment, etc., can solve the problems of restricting the expansion of application range, low production extrusion speed, and thermal cracks on the profile surface , to achieve the effect of preventing periodic extrusion cracks or oxidation, avoiding local overheating, and preventing profile fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ZK60 magnesium alloy profile rapid extrusion method, the steps of the method are as follows:

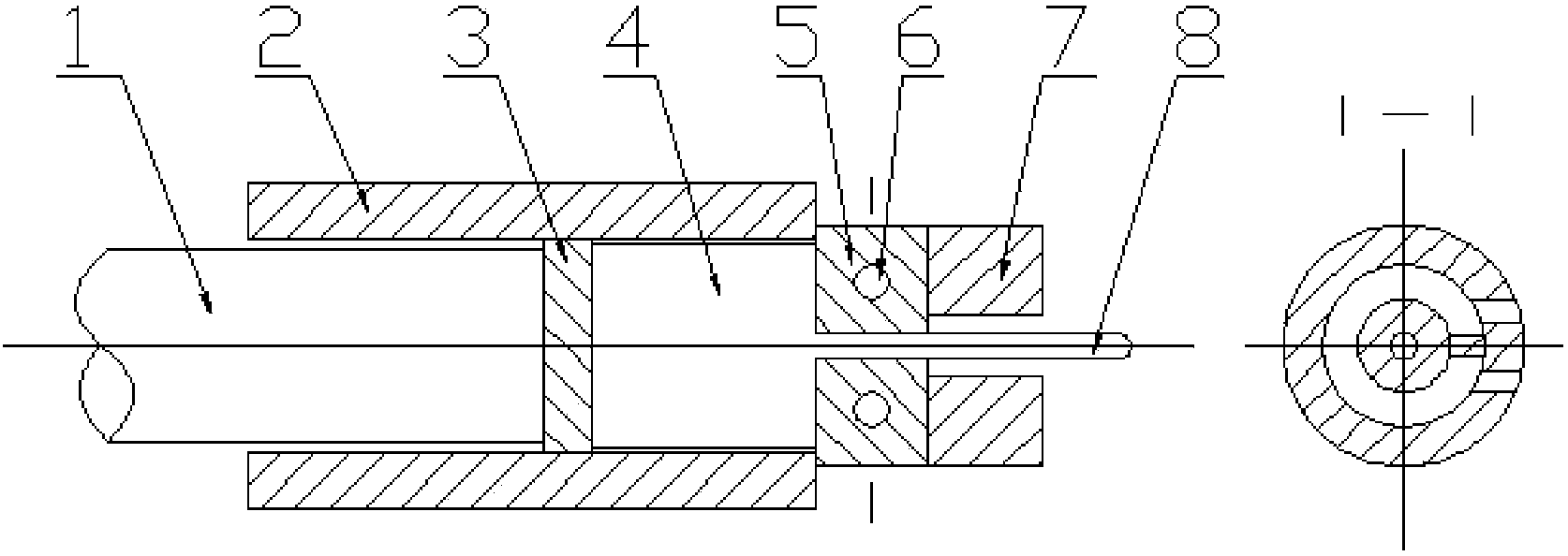

[0024] 1. The section shape of the profile is circular with a diameter of 20mm. Design and manufacture extrusion die 5 and cooling pipe 6 according to ZK60 magnesium alloy profile cross section, select 800 ton extrusion machine, extrusion barrel 2 diameter is 125mm; extrusion ratio is 39;

[0025] 2. According to the composition requirements of ZK60 magnesium alloy, the ZK60 magnesium alloy cast rod 4 with a diameter ratio of 125mm is capacity-cast, and it is homogenized in a heat treatment furnace, and the surface scale is removed by 1-2mm. The temperature is 350℃~450℃, and the time is 12~32h;

[0026] 3. Preheat the extrusion shaft 1, extrusion barrel 2, extrusion pad 3, magnesium alloy cast rod 4, extrusion die 5, the preheating temperature is 300 ° C ~ 450 ° C, and install the extrusion die 5 to the extrusion On the machine, connect the thermocouple and the mold cooling ...

Embodiment 2

[0029] The cross-section of the profile is changed to a square, the cross-sectional size is 10mm×10mm, the cooling medium used is heat transfer oil, and the rest are the same as the steps of embodiment 1.

Embodiment 3

[0031] The cross-section of the profile is changed to a rectangle, the cross-sectional size is 20mm×5mm, the cooling medium used is water, and the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com