Method for improving biomedical magnesium alloy corrosion resistance through micro-arc oxidation

A micro-arc oxidation, biomedical technology, applied in anodic oxidation, medical science, prosthesis, etc., can solve the problem of weakening the corrosion resistance of the coating, and achieve the effects of easy access, excellent corrosion resistance, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

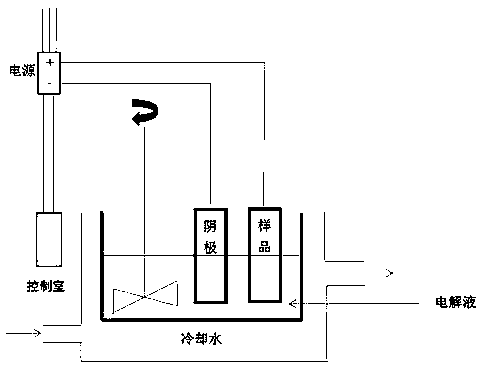

Embodiment 1

[0030] Cut the ZK60 magnesium alloy into 20*20*5mm sample blocks with an electric spark cutting machine, and drill through holes on the surface with an electric drill. Sand the magnesium alloy with 2000-grit sandpaper to obtain a bright surface. The polished magnesium alloy is ultrasonically cleaned with ethanol and dried. Harbin Institute of Technology WHD20 equipment is used, the positive voltage is 250V, the negative voltage is 20V, the working frequency is 600Hz, the positive duty cycle is 30%, the negative duty cycle is 70%, and the number of positive and negative pulses is 1. The electrolyte is 0.05mol / L Na3PO4, 0.02mol / L Na2B4O7, 0.05mol / L KOH, the reaction time is 15min, the prepared solution is poured into the electrolytic tank, and the stirring device is started to stir the solution to make the solution evenly mixed, using 304 stainless steel The wire passes through the magnesium alloy, the magnesium alloy is immersed in the electrolyte, and the stainless steel wire...

Embodiment 2

[0032] Cut the ZK60 magnesium alloy into 20*20*5mm sample blocks with an electric spark cutting machine, and drill through holes on the surface with an electric drill. Sand the magnesium alloy with 2000-grit sandpaper to obtain a bright surface. The polished magnesium alloy is ultrasonically cleaned with ethanol and dried. Harbin Institute of Technology WHD20 equipment is used, the positive voltage is 300V, the negative voltage is 20V, the working frequency is 600Hz, the positive duty cycle is 30%, the negative duty cycle is 70%, and the number of positive and negative pulses is 1. The electrolyte is 0.05mol / L Na3PO4, 0.02mol / L Na2B4O7, 0.05mol / L KOH, the reaction time is 15min, the prepared solution is poured into the electrolytic tank, and the stirring device is started to stir the solution to make the solution evenly mixed, using 304 stainless steel The wire passes through the magnesium alloy, the magnesium alloy is immersed in the electrolyte, and the stainless steel wire...

Embodiment 3

[0034] Cut the ZK60 magnesium alloy into 20*20*5mm sample blocks with an electric spark cutting machine, and drill through holes on the surface with an electric drill. Sand the magnesium alloy with 2000-grit sandpaper to obtain a bright surface. The polished magnesium alloy is ultrasonically cleaned with ethanol and dried. Harbin Institute of Technology WHD20 equipment is used, the forward voltage is 350V, the negative voltage is 20V, the working frequency is 600Hz, the positive duty cycle is 30%, the negative duty cycle is 70%, and the number of positive and negative pulses is 1. The electrolyte is 0.05mol / L Na3PO4, 0.02mol / L Na2B4O7, 0.05mol / L KOH, the reaction time is 15min, the prepared solution is poured into the electrolytic tank, and the stirring device is started to stir the solution to make the solution evenly mixed, using 304 stainless steel The wire passes through the magnesium alloy, the magnesium alloy is immersed in the electrolyte, and the stainless steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com