ZK60 magnesium alloy and preparation method thereof

A magnesium alloy and alloy liquid technology, applied in the direction of metal extrusion dies, etc., can solve problems such as uneven plastic deformation, and achieve uniform deformation of blanks, low production costs, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical scheme of the present invention is described in detail below in conjunction with specific embodiment:

[0034] A kind of ZK60 magnesium alloy, its component mass percent is: 2.5-3% Al, 0.8-1.2% Zn, 0.15-0.2% Mn, 0.06% Si, 0.03% Cu, 0.02% Ni, 0.01% Fe, the balance of Mg .

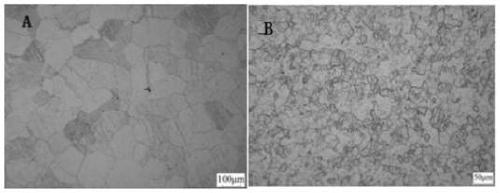

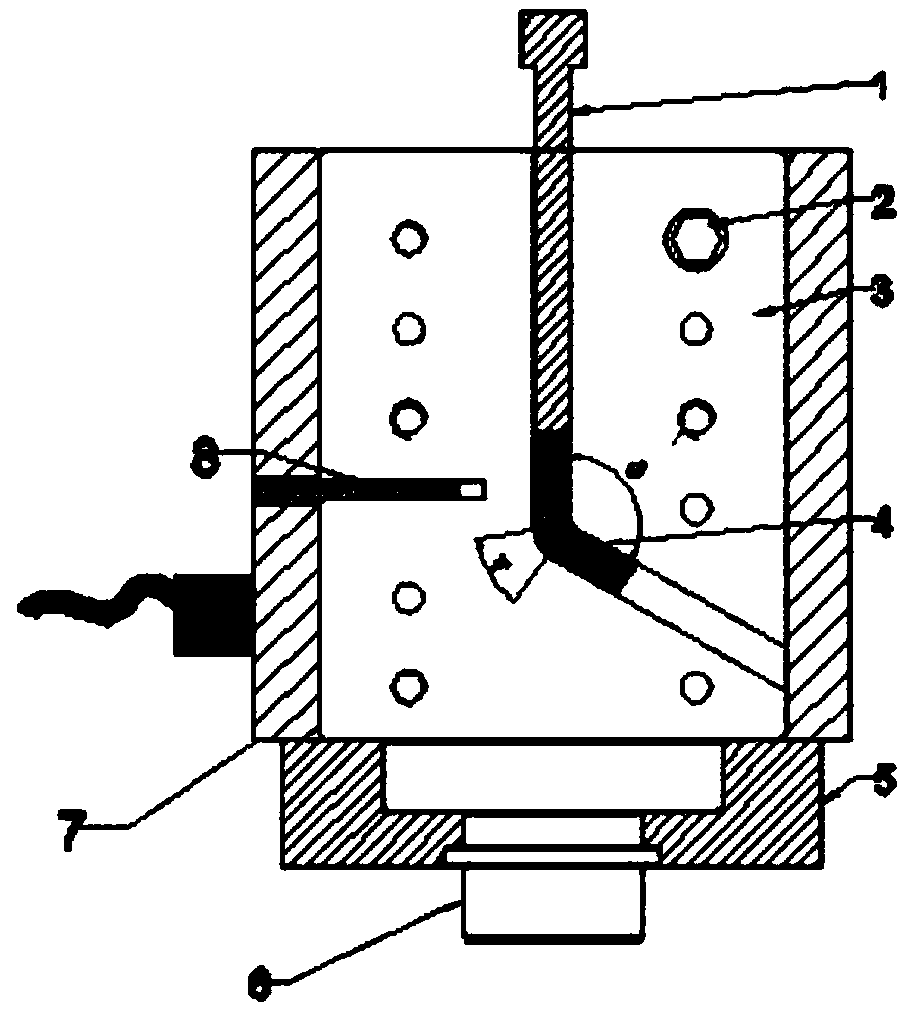

[0035] Its preparation method includes the following steps: (1) select each raw material according to the above mass ratio, and preheat the selected raw materials at 260°C respectively, heat and melt them under a protective atmosphere SF6 to form a melt, and the melting temperature is 760°C ~850°C, heat preservation, so as to form alloy liquid; (2) reduce the temperature of the alloy liquid, and then introduce high-purity argon for refining, obtain refined alloy liquid after heat preservation and standing, and the refined alloy liquid The magnesium alloy rod is poured into a mold, cooled and solidified to obtain a magnesium alloy rod, and the magnesium alloy rod is extruded through a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com