Ultrafast cooling device for large rolled H-shaped steel

An ultra-rapid cooling, H-beam technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of increased production cost, uneven structure, inability to meet users, etc., to improve economic benefits, reduce The effect of improving production cost and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

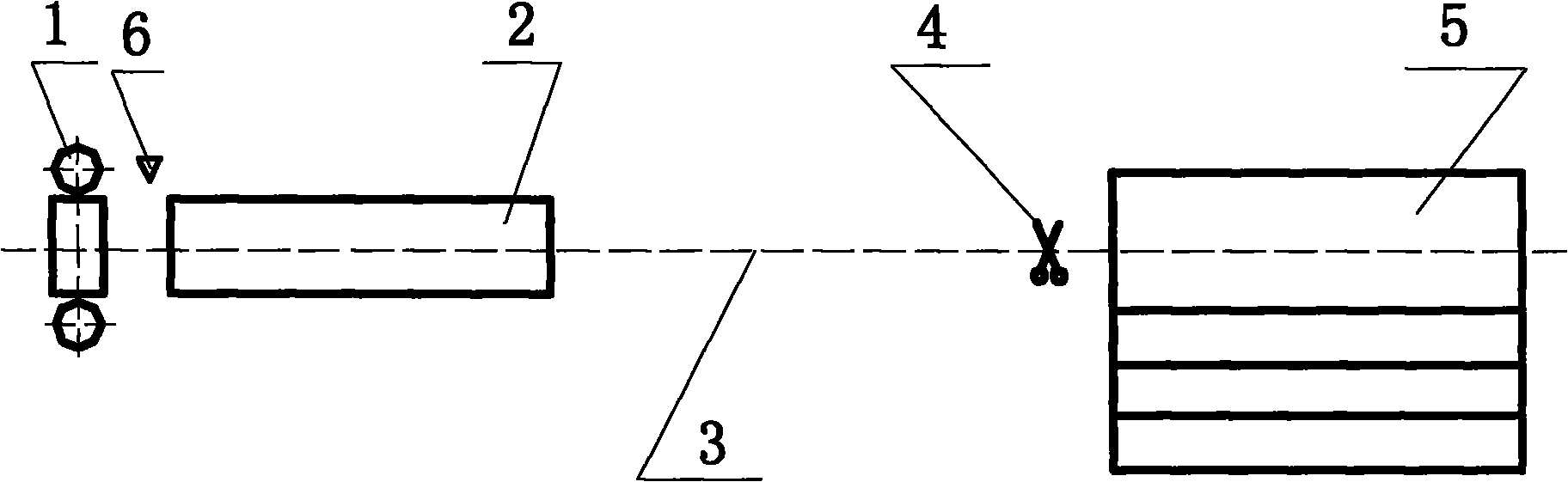

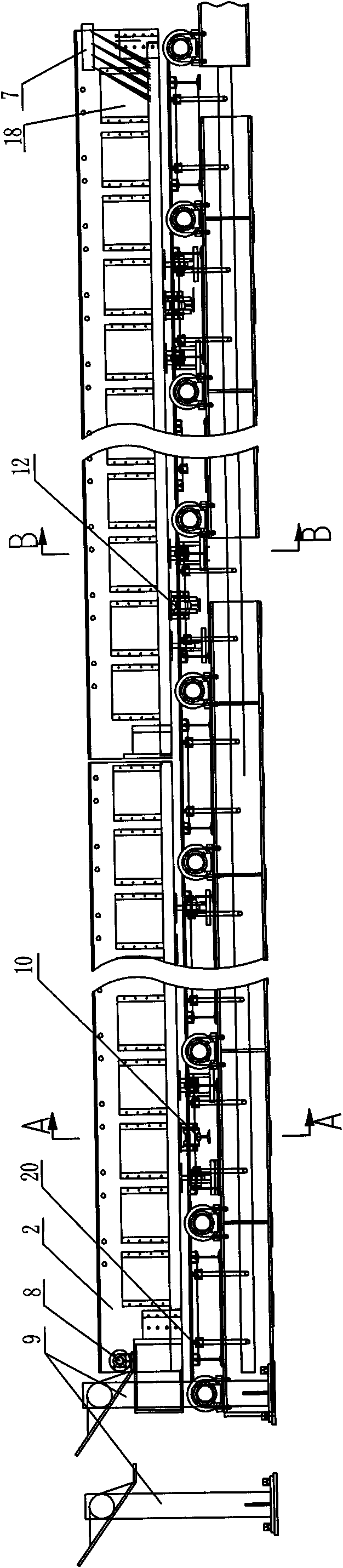

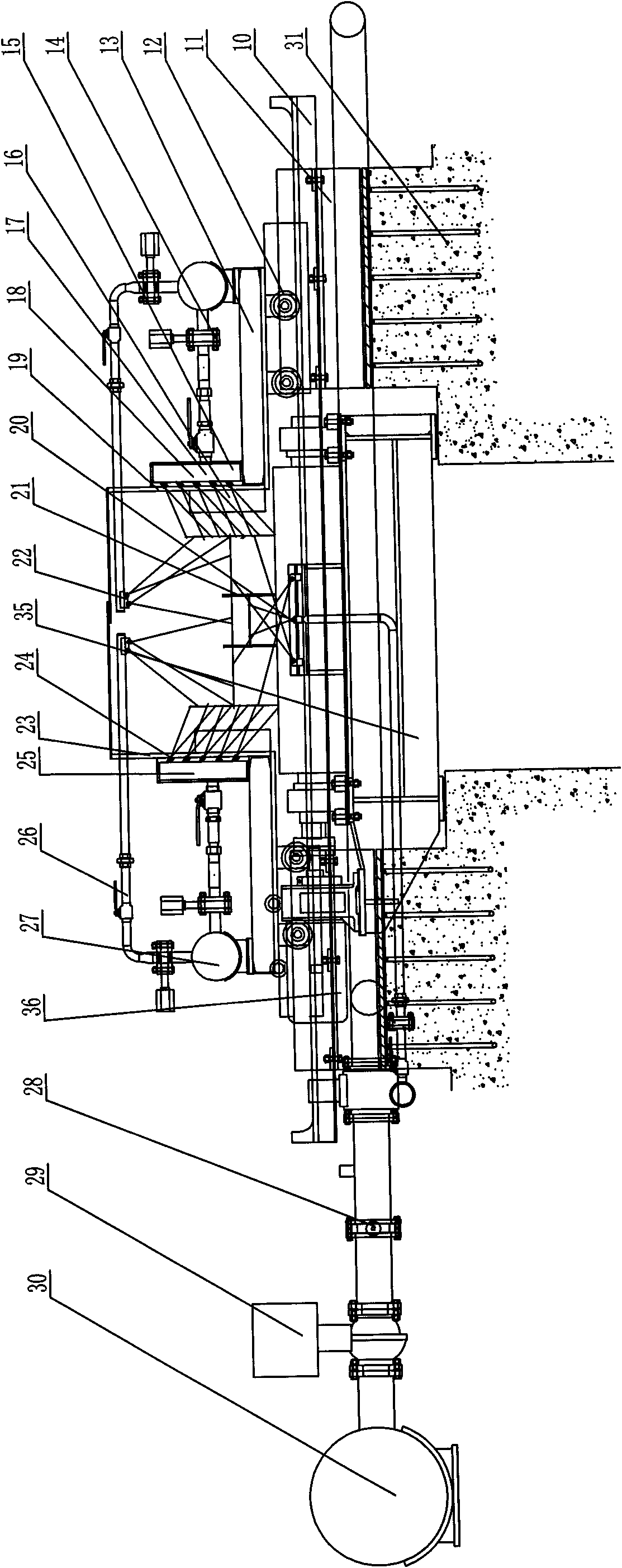

[0033] A set of ultra-rapid cooling device of the present invention was installed after the H-shaped steel finished universal rolling mill in a certain factory, and its installation position is as follows figure 1As shown, the ultra-rapid cooling device adopts water spray cooling method. The finished size of the rolled H-shaped steel is HM390×300×16×10, and the steel type is Q345B. The billet is first rolled for 5 passes in the two-roll billet mill, then rolled for 5 passes in the universal roughing mill unit in the form of UEU, and finally rolled for 1 pass in the finished universal rolling mill.

[0034] The H-shaped steel enters the ultra-rapid cooling device of the present invention to cool after the finished product universal rolling mill is rolled, and each group of upper nozzle units in the ultra-rapid cooling device has two nozzles to cool the upper R angle and the upper web of the H-shaped steel respectively. The lower nozzle unit of the group has three nozzles, resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com