Vehicular power maintenance system with maintenance tool box

A technology for power maintenance and maintenance tools, which is applied to vehicle parts, lifting devices, transportation and packaging, etc. It can solve the troublesome problems of unfolding and putting away tents, and inconvenient carrying, so as to achieve safe storage of items, avoid loss and theft, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

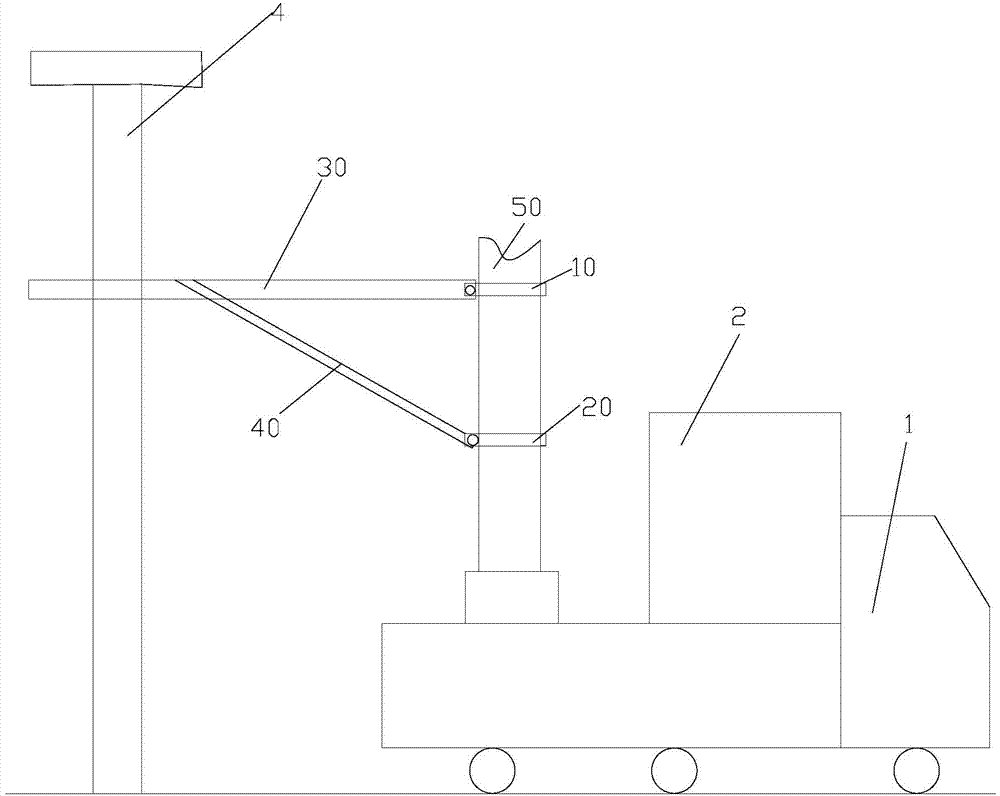

[0034] Such as Figures 1 to 5 As shown, the present embodiment has a vehicle-mounted power maintenance system with a maintenance toolbox, which is used to repair objects to be maintained, and includes:

[0035] The vehicle main body 1 is movably arranged on the ground so as to quickly reach the maintenance site;

[0036]a lifting device provided on the vehicle body;

[0037] a maintenance bracket arranged on the lifting device;

[0038] The maintenance support includes a support column 50 connected to the lifting device, a first fixing member 10, a second fixing member 20 arranged on the support column at intervals up and down, and a maintenance platform 30, the first end of the maintenance platform It is arranged on the first fixing part; it also includes a reinforcing bracket 40 connecting the maintenance platform and the second fixing part, the first end of the reinforcing bracket is connected to the second fixing part, and the reinforcing bracket The second end of the ...

Embodiment 2

[0051] Such as Figure 6 As shown, on the basis of Embodiment 1, this embodiment further includes an emergency power supply device arranged above the maintenance platform. The emergency power supply device includes a light bulb and a built-in circuit board, and the built-in circuit board is provided with a power supply circuit, a light control circuit, an external control circuit, a remote control circuit, a fault indication circuit and a battery charging circuit; , an external control circuit, and a battery charging circuit; the lamp control circuit is connected with an external control circuit and a light bulb; the fault indication circuit is connected with a lamp control circuit and an external control circuit; the battery charging circuit is provided with battery, and is connected with the light control circuit; the remote control circuit is mainly composed of intermediate relay K2, capacitor C, pulse signal switch KM, pulse signal generator MC and remote signal receiver R...

Embodiment 3

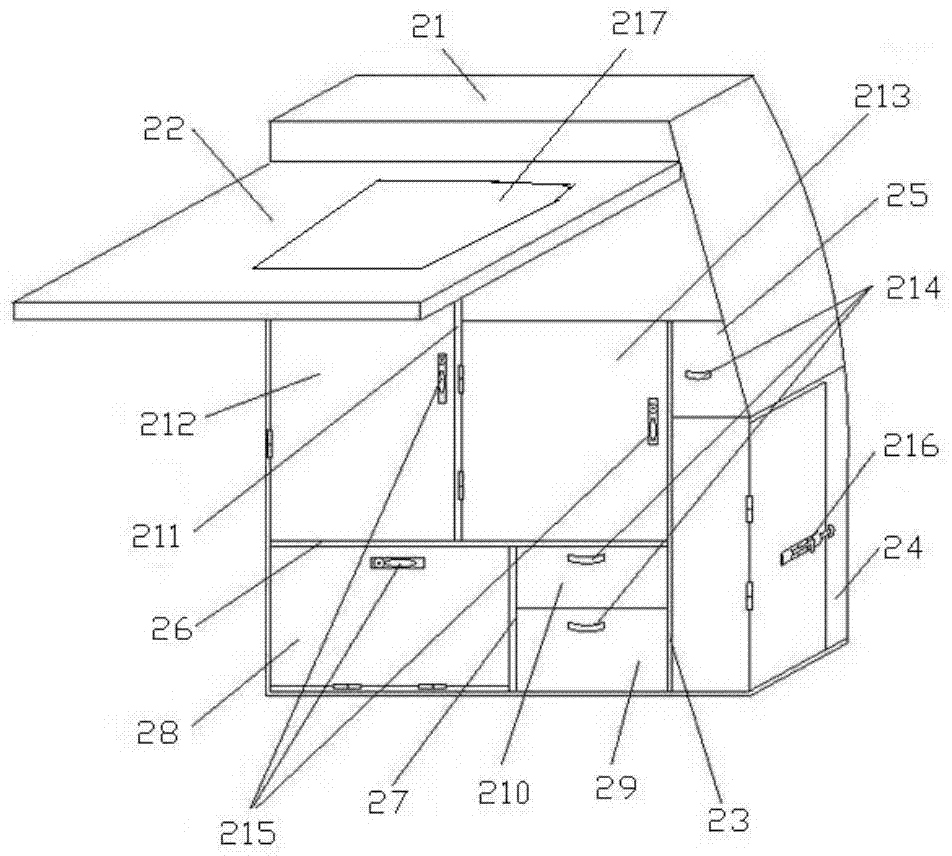

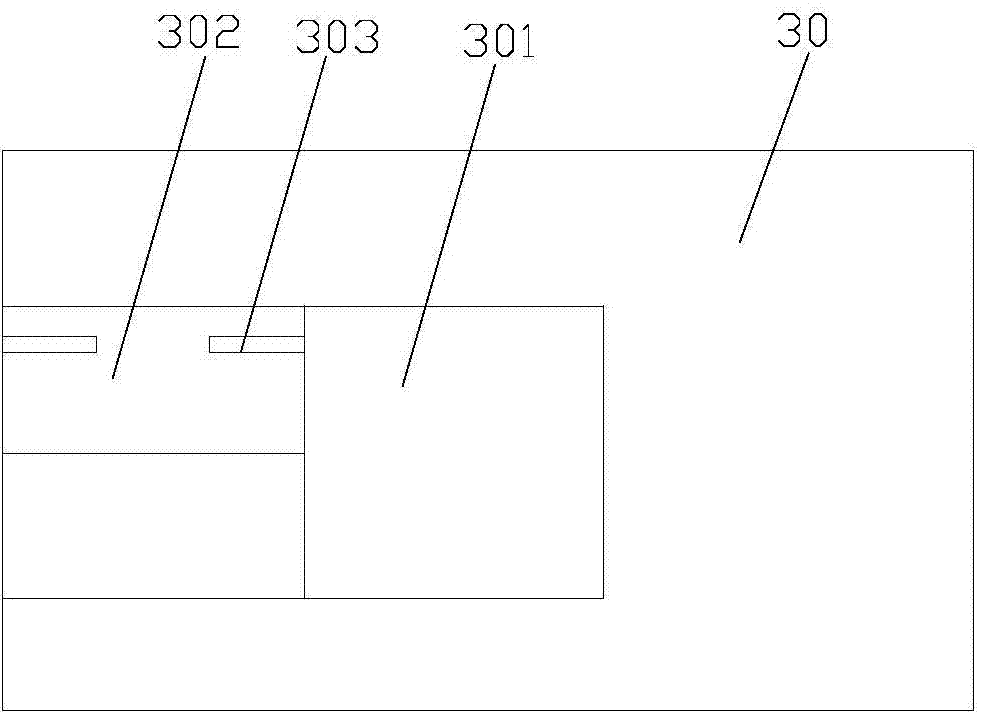

[0054] Such as Figures 7 to 8 As shown, on the basis of Embodiment 1, the vehicle-mounted power maintenance system with a maintenance toolbox in this embodiment further improves the maintenance bracket. The maintenance bracket includes a first fixing part 10 , a second fixing part 20 , a maintenance platform 30 and a reinforcement bracket 40 . Wherein, the first fixing part 10 and the second fixing part 20 are arranged on the supporting column, and are arranged at intervals up and down; the first end of the maintenance platform 30 is arranged on the first fixing part 10; the first end of the reinforcing bracket 40 is connected to On the second fixing member 20 , the second end of the reinforcement bracket 40 is connected to the second end of the maintenance platform 30 , and the second end of the maintenance platform 30 is far away from the support column.

[0055] A triangular structure is formed between the maintenance platform, the reinforcement bracket and the support co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com