Self-adhesive glue for polymer waterproof coiled material, preparation method thereof, and polymer waterproof coiled material

A polymer waterproof and self-adhesive technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve weak bonding strength, warped edges, and weak bonding of waterproof membranes and other problems, to achieve the effect of enhancing hardness, increasing bonding strength, and internal tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0043] Preparation Example 1: Preparation of Modified Nano Titanium Dioxide

[0044] S1. Weigh 60g of silane coupling agent and 400g of nano-titanium dioxide, add them into a three-necked flask, and adjust the pH to 9;

[0045] S2. Put the three-necked flask into a constant temperature water tank, control the temperature at 58°C, stir at 100r / min for 2h, filter, and wash with deionized water three times to obtain the mixture;

[0046] S3, sending the mixture to a muffle furnace, and drying at 85° C. for 2 hours to obtain modified nano-titanium dioxide.

preparation example 2

[0047] Preparation Example 2: Preparation of modified nano-titanium dioxide filled alkyd resin

[0048] S1. Weigh 200 g of the modified nano-titanium dioxide prepared in Preparation Example 1, put it into a reaction kettle together with 10 kg of alkyd resin, and stir and mix for 2 minutes to obtain a mixture;

[0049] S2. Put the mixture in an ultrasonic emulsification disperser, and ultrasonically disperse for 30 minutes to obtain a modified nano titanium dioxide filled alkyd resin.

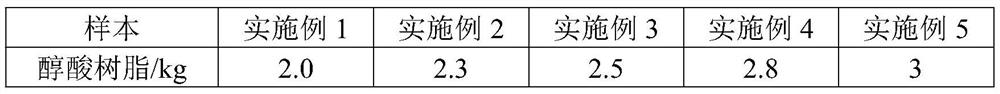

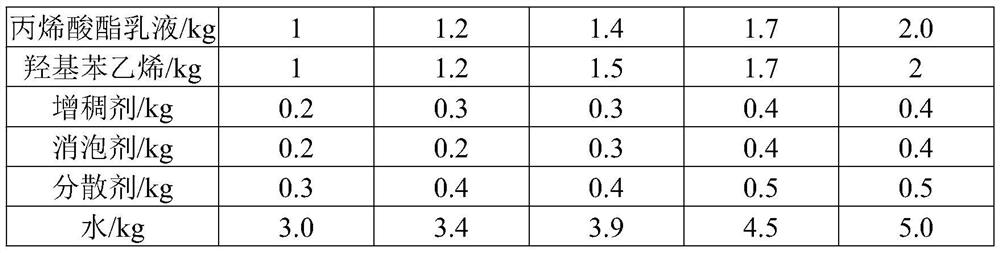

Embodiment 1~5

[0052] As shown in Table 1, the main difference of Examples 1-5 is that the ratio of raw materials is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com