Fireproof interlayer glue, preparation method thereof and fireproof glass containing fireproof interlayer glue

The technology of interlayer adhesive and sol is applied in the field of fireproof glass, fireproof interlayer adhesive and its preparation, which can solve the problems of poor dispersion uniformity, poor stability, and lack of consideration, and achieve good dispersion, improve fire resistance, and prevent the effects of precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

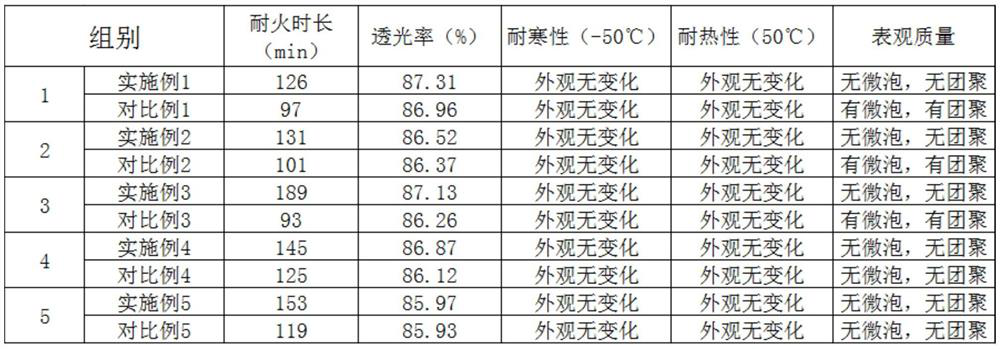

Examples

preparation example Construction

[0038] A method for preparing a fire-resistant interlayer adhesive, comprising: (1) adding a heat-resistant dispersant and a stabilizer to nano-silica sol, gradually raising the temperature to 60-80°C during stirring, and then stirring for 20-30min to obtain silicon Sol dispersion; (2) After cooling the silica sol dispersion to room temperature, add inorganic alkali solution, flame retardant, defoamer, and anti-condensation agent to the silica sol dispersion in sequence, stir evenly, and heat up to 30-80°C , and stirred under vacuum conditions for 15-40min, filtered, and cooled to room temperature to obtain a fireproof interlayer adhesive. The method only includes two steps of preparing the silica sol dispersion and mixing the silica sol dispersion with other components, the preparation process is simple, and the production cost is low.

[0039] As a further embodiment, the vacuum condition is 0.1-0.3MPa; filtration is carried out using a 150-200 mesh screen, and vacuum stirri...

Embodiment 1

[0045] A fireproof interlayer adhesive, comprising the following raw materials in parts by weight: 45 kg of nano-silica sol, 35 kg of inorganic alkali solution, 0.8 kg of heat-resistant dispersant, 0.6 kg of stabilizer, 0.2 kg of flame retardant, and 0.6 kg of defoaming agent kg, anti-condensation agent 5kg;

[0046] Wherein, the stabilizer is β-cyclodextrin; the heat-resistant dispersant is glycerin; the inorganic alkali solution is a mixed solution of potassium hydroxide and sodium hydroxide, and the moles of potassium hydroxide and sodium hydroxide The ratio is 1.5:1.

[0047] The mass concentration of the nano-silica sol is 45%.

[0048] The mass concentration of the inorganic alkali solution is 55%.

[0049] The flame retardant is liquid phosphite; the defoamer is emulsified silicone oil and polyoxypropylene glyceryl ether; the anticondensation agent is ethylene glycol and propylene glycol.

[0050] A method for preparing a fireproof interlayer adhesive, characterized ...

Embodiment 2

[0057] A fireproof interlayer adhesive, comprising the following raw materials in parts by weight: 50 parts of nano-silica sol, 25 kg of inorganic alkali solution, 1.6 kg of heat-resistant dispersant, 0.1 kg of stabilizer, 0.8 kg of flame retardant, and defoamer 0.1kg, anti-condensation agent 15kg;

[0058] Wherein, the stabilizer is β-cyclodextrin; the heat-resistant dispersant is glycerin; the inorganic alkali solution is a mixed solution of potassium hydroxide and sodium hydroxide, and the moles of potassium hydroxide and sodium hydroxide The ratio is 4:1.

[0059] The mass concentration of the nano-silica sol is 50%.

[0060] The mass concentration of the inorganic alkali solution is 45%.

[0061] The flame retardant is liquid phosphite; the defoamer is polyoxypropylene oxide ethylene glyceryl ether; and the anticondensation agent is glycerol and pentaerythritol.

[0062] A method for preparing a fireproof interlayer adhesive, characterized in that it comprises: (1) add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com