Hot work die steel H13 and continuous casting and rolling manufacturing process thereof

A technology of hot work die steel and manufacturing process, which is applied in the field of steel manufacturing, can solve the problems of high viscosity of molten steel, unqualified round steel flaw detection, high alloy content, etc., and achieve the effect of reducing slag after tapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

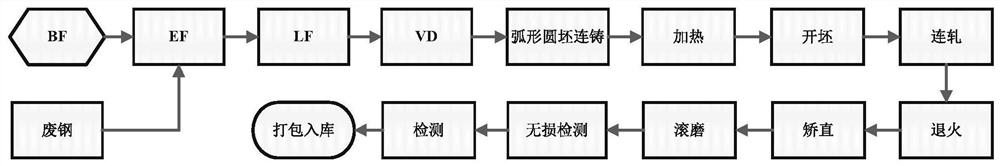

[0035] Such as figure 1 Shown, the production process of H13 continuous casting and rolling round of the present invention is shown in the appendix figure 1 , including the following steps:

[0036] Step S1, molten steel smelting: the blast furnace smelts coke and ore into molten iron, then puts molten iron and steel scrap into the electric furnace, blows oxygen into the molten pool of the electric furnace, adds lime to form slag, and the proportion of molten iron mixed into the electric furnace is not less than the total amount of molten iron and steel scrap. 85% of the quality. When the temperature is 1560°C, the phosphorus content in the steel is removed by slag replacement and furnace door slag flow. The mass ratio of tapping carbon is controlled at 0.10-0.15%, and the mass ratio of tapping phosphorus is controlled below 0.005%. The steel is tapped at the eccentric bottom of the furnace. When the molten steel reaches 1 / 4 of the ladle, lime, metal manganese, and low Ca...

Embodiment 2

[0053] A manufacturing process of high-quality hot work die steel H13 continuous casting and rolling round, its chemical composition, smelting method, and rolling process are all the same as in Example 1, the differences are as follows:

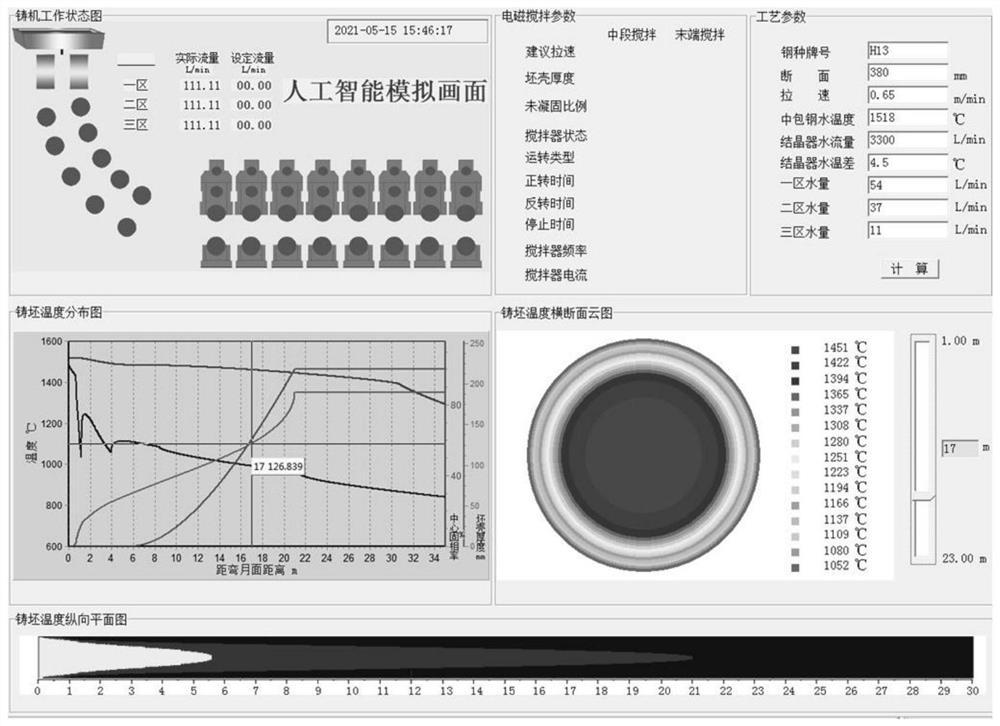

[0054] (1) if figure 2 The specification of continuous casting round billet is The casting speed is 0.65m / min, using the combination of M-EMS, S-EMS, and F-EMS, the parameters are: 250A / 2Hz, 200A / 8Hz, 1100A / 8Hz, in which S-EMS adopts forward and reverse rotation, and stops in the middle The time is 12 seconds. The samples were taken from the continuous casting tundish, and the chemical composition is shown in Table 4.

[0055] Table 4 Chemical composition wt%

[0056] Furnace batch number C Si mn P S Cr Ni Cu Mo V Nb Ti 3343 0.37 1.00 0.34 0.007 0.001 5.19 0.04 0.04 1.35 0.99 0.013 0.0041 Furnace batch number Al Ca B N H O Pb As sn Sb Bi ∑ five evils 3343 0.025 0.0...

Embodiment 3

[0063] A kind of manufacturing process of high-quality hot work die steel H13 continuous casting and rolling round, its chemical composition, smelting method, rolling process are all the same as Embodiment 1 and 2, the difference is as follows:

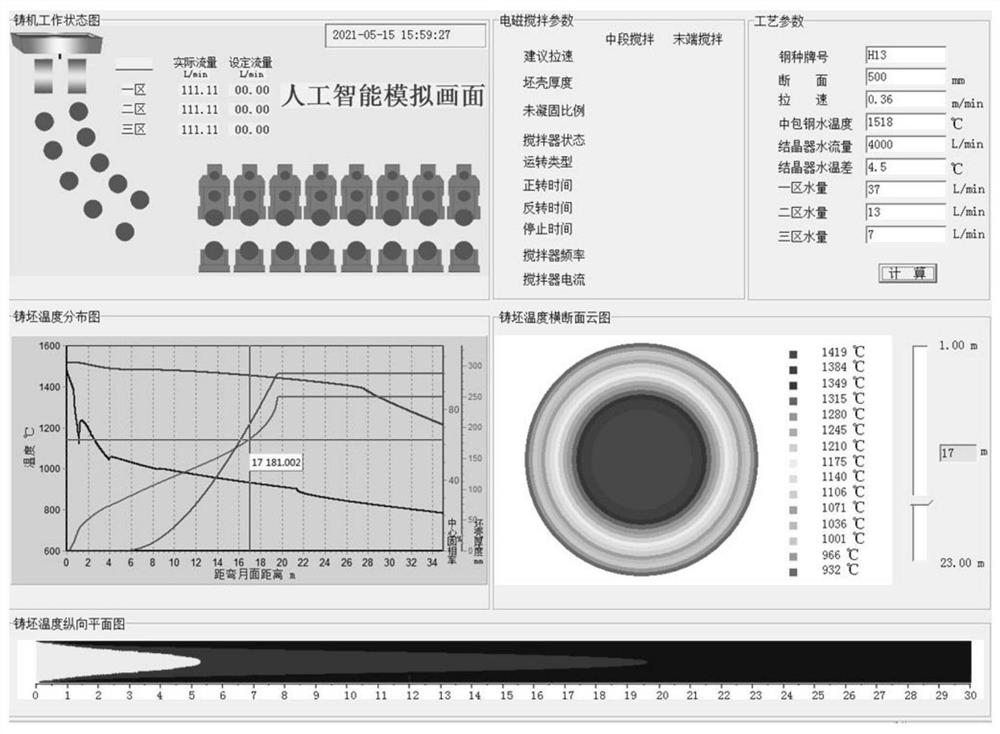

[0064] (1) The specification of continuous casting round billet is The casting speed is 0.36m / min, and the combination of M-EMS, S-EMS, and F-EMS is used. The parameters are: 250A / 2Hz, 600A / 5Hz, and 1100A / 8Hz, and the electromagnetic stirring is all forward. The samples were taken from the continuous casting tundish, and the chemical composition is shown in Table 6.

[0065] Table 6 Chemical composition wt%

[0066]

[0067]

[0068] (2) When the continuous casting slab is between 550-650°C, it is sent into the heating furnace. The actual performance of the heating furnace is shown in Table 7.

[0069] Table 7 Heating performance

[0070]

[0071] (3) After the round steel has been annealed, straightened, rolled and inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com